GETTINGTOKNOWYOURWINCH

GETTINGTOKNOWYOURWINCH

Your 3500lb winch is a powerful piece of machinery. It is important that you understand the

basics of its operation and specifications so that when you need to use it, you can use it with

confidence and safety. Below is a list of the components of your winch and their use. Practice

using your winch before you are in a situation where you need to use it.

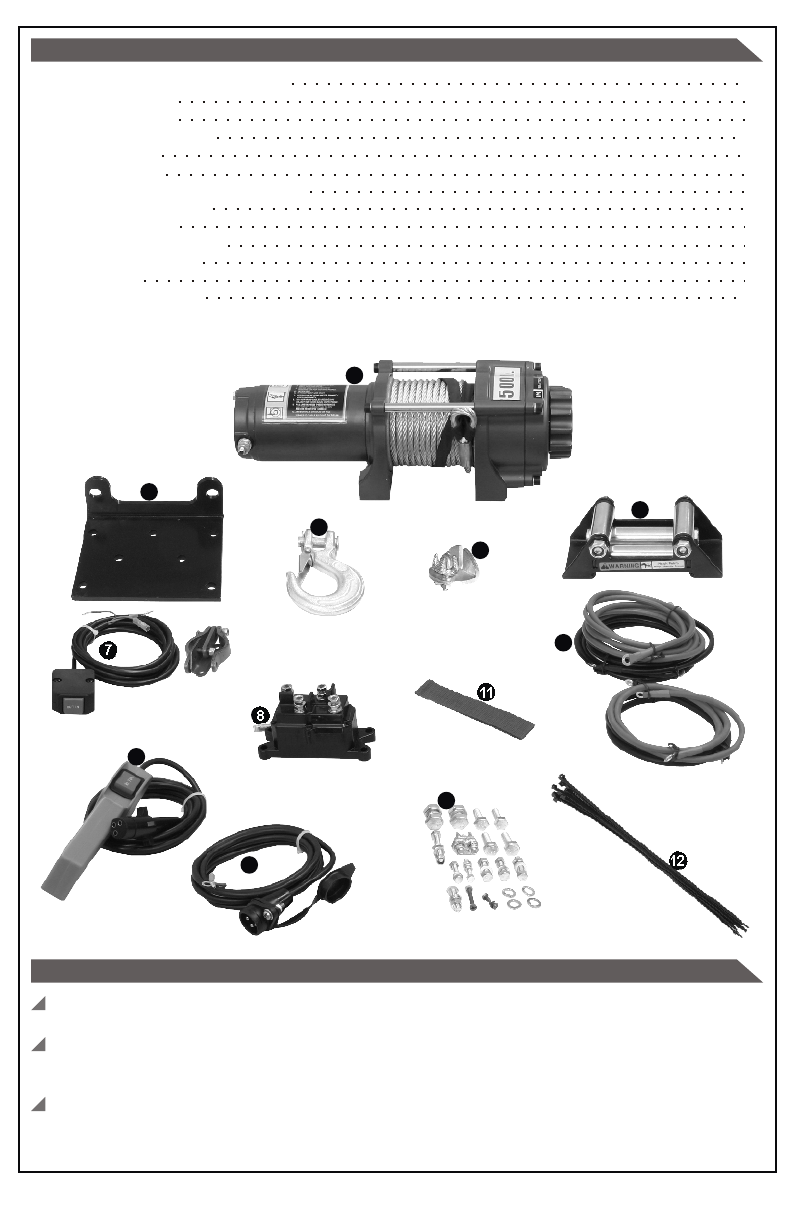

Motor: Your 1.3hp motor is powered by a 12 volt battery and provides power to the gear

mechanism which turns the drum and winds the wire rope;

Winch Drum: The winch drum is the cylinder on which the wire rope is stored. It can feed or

wind the rope depending on the remote winch switch.

Wire Rope: Your winch has a 7/32"X42' galvanized aircraft cable designed specifically for

load capacity of 3500lbs. The wire rope feeds onto the drum in the “under wind” position

through the roller fairlead and is looped at the end to accept the clevis hook pin.

Roller Fairlead: When using the winch at an angle the roller fairlead acts to guide the wire

rope onto the drum and minimizes damage to the wire rope from abrasion on the winch

mount or bumper.

Mechanic Gear System: The reduction gears convert the winch motor power into extreme

pulling forces.

Braking System: Braking action is automatically applied to the winch drum when the winch

motor is stopped and there is a load on the wire rope. The braking action is applied by a

separate mechanical brake.

Free Spooling Clutch: The clutch allows the operator to manually disengage (“Out”) the

spooling drum from the gear train, free spool. Engaging the clutch (“In”) locks the winch into

the gear system.

Control System: your winch has multiform operations for a variety of applications, you can

directly control your winch by using Power Cord/Switch Assembly, you can also control your

winch through a solenoid control box by pressing a button on the power switch you selected

to use.

Solenoid: Power from the vehicle battery flows through the weather sealed switch before

being directed to the winch motor.

Remote Switch: The Power switch leads has a dual switch for powering in or powering out

your winch drum. The Power switch leads allow you to stand clear of the wire rope when the

winch is under load.

Universal Flat Bed Mounting Plate: Your winch is being supplied with a flat bed mounting

plate that can be mounted to most flat surfaces such as trailers, step bumpers, truck beds,

etc. The mounting plate also has holes to accept your roller fairlead.

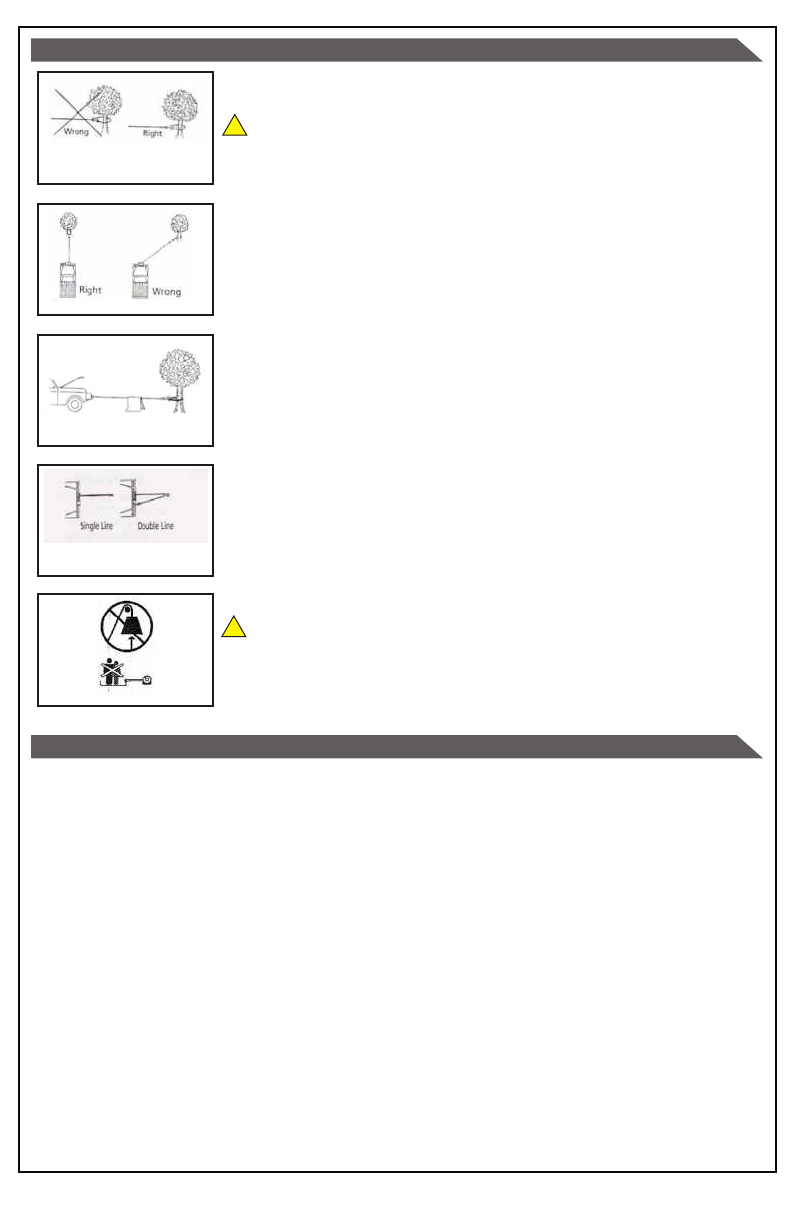

Get to know your winch before you actually need to use it. We recommend that you set up a few

test runs to familiarize yourself with rigging techniques, the sounds your winch makes under

various loads, the way the cable spools on the drum, etc.

Inspect the wire rope and equipment before each use. A frayed or damaged rope shall be

replaced immediately. Use only manufacturer's identical replacement rope with the exact

specifications.

Inspect the winch installation and bolts to ensure that all bolts are tight before each operation.

Never connect the cable back to itself. This will cause cable damage. Always use a snatch

block, sling or chain of suitable strength.

Store the remote control inside your vehicle in a place that it will not be damaged.

Any winch that appears to be damaged in any way, is found to be worn, or operates abnormally

SHALL BE REMOVED FROM SERVICE UNTIL REPAIRED. It is recommended that the

necessary repairs be made by a manufacturer's authorized repair facility.

Pull only on areas of the vehicle as specified by the vehicle manufacturer.

Only attachments and/or adapters supplied by the manufacturer shall be used.

3