Tractor Supply Traveller X Training manual

Tractor Supply Company ○

R0

www.tractorsupply.com For customer support call 1-888-376-9601 0

10000lb.Winch

User Manual & Operating Instructions

Performance Specifications

Max Line Pull

10000lbs.(4536kgs)

Gear reduction ratio

253:1

Motor

Series wound DC12V motor with 2.8hp output

Overall Dimensions

22.9in.( 582mm) L × 6.9in.( 175mm) W × 8.94in.( 227mm) H

Drum size

2.48in.( 63mm) D × 8.54in.( 217mm) L

Remote Controller

Max control distance 30m

Rope

82ft.(25.0m) L of 25/64in.(10mm) D

Net weight

69.7lbs.(31.6kgs)

Product Overview

This winch is equipped with a series wound motor and is designed for intermittent duty

general use. This winch is not to be used for industrial lifting or moving people.

Improper operation could damage the winch and void the warranty.

Free spool clutch is operated by a pull and turn knob, which disengages the gearbox,

allowing the cable to be released.

www.tractorsupply.com For customer support call 1-888-376-9601 12

INSTALLATION

Correct installation of the winch is required for proper operation.

Mount the winch on the vehicle or other fixed installation by using a screw

(M10×1.5×35mm), M10 nut, ∅10 flat washer and ∅10 spring washer (four sets).

WARNING: This winch must be mounted with the cable in an under wound direction.

Improper mounting could damage the winch and void the warranty.

Connect the red wire to the positive terminal and the black wire to the negative

terminal of the battery.(See Fig. 1).

Fig. 1

Check the rotation direction of the drum. Pull and turn the clutch knob to the

“OUT” position (drum should turn freely by hand). Pull out some cable from the

drum, and then turn the clutch knob to the “IN” position. Press the “OUT” button on

the switch; if the cable is releasing then it is properly connected. Otherwise

reverse the wire connections to the motor, and repeat the above-mentioned

operation.

www.tractorsupply.com For customer support call 1-888-376-9601 22

OPERATION

Pull and turn the clutch knob, so the drum can turn freely by hand.

Use hand saver bar to hitch the hook of the cable assembly and pull cable to the

load. Attach the cable hook to the load.

WARNING: Check that there are at least five turns of cable remaining on the drum

before operation. Ensure the clutch knob is in the engaged position.

CAUTION: Clutch must be fully engaged before winching.

Never operate the clutch while drum is turning. Do not readjust clutch knob as it has

been adjusted and permanently locked in place with a thread-locking compound in the

factory.

Press the “IN” button on the switch to re-spool the cable. Press the “OUT” button

to reverse directions. Wait until the motor stops before reversing directions.

Re-spool the cable after completing the operation.

REPLACING THE CABLE

Engage the clutch by turning the clutch knob to the “IN” position.

When inserting the cable into the drum, insert it into the correct end of the hole

provided. Tighten the screws.

Operate the winch an re-spool the cable around the drum tightly.

CAUTION: To keep the stated tension, be sure the cable is wrapped on the drum

tightly.

WARNING: Always replace damaged cable with manufacturer’s identical

replacement part.

MAINTENANCE

Periodically check tightness of mounting bolts and electrical connections. Remove

all the dirt or corrosion and always keep clean.

Do not attempt to disassemble the gearbox. Repairs should be done by the

manufacturer or authorized repair center.

The gearbox has been lubricated using high temperature lithium grease in the

factory. No internal lubrication is required except when being repaired.

When the transmitter is replaced, the same type of transmitter is required for

pairing. The pairing method is as follows:

Press the power button →Press IN and OUT button at the same time (the red light

was flashing) →Turn on receiver for 1-2s (the relay makes a sound of absorption)

www.tractorsupply.com For customer support call 1-888-376-9601 32

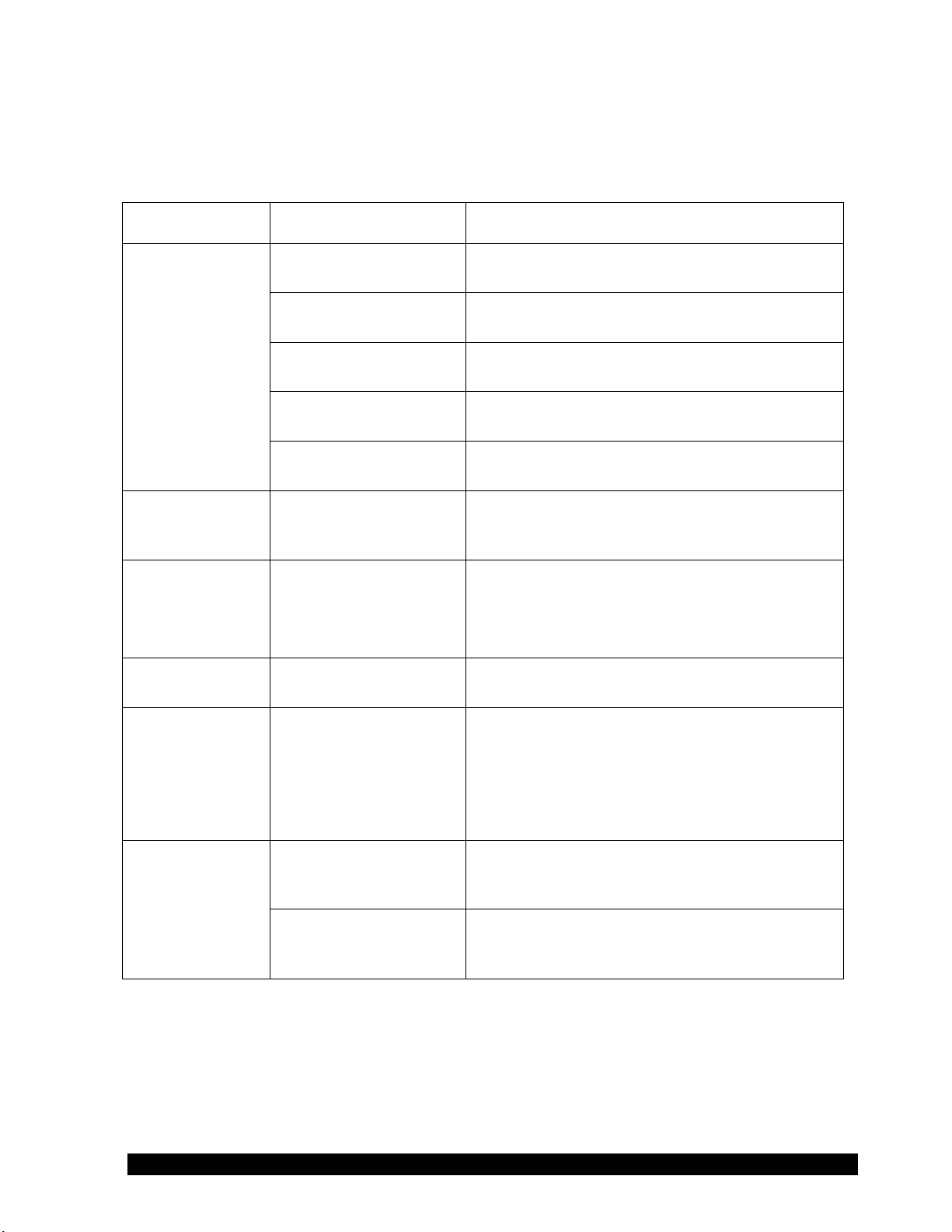

TROUBLE SHOOTING

SYMPTOM

POSSIBLE CAUSE

SUGGESTED ACTION

Motor does not

turn on

-Switch Assembly not

connected properly

-Insert switch assembly all the way into the

connector.

-Loose battery cable

connections

-Tighten nuts on all cable connections.

-Defective switch

assembly

-Replace switch assembly.

-Defective motor

-Check voltage at armature port while switch

pressed. If voltage is normal, replace motor.

-Water has entered

motor

-Allow to drain and dry. Run in short bursts

without load until completely dry.

Motor runs but

cable drum does

not turn

-Clutch not engaged

-Turn clutch to the “In” position. If problem

remains, a qualified technician needs to check

and repair.

Motor runs

slowly or without

normal power

-Insufficient current or

voltage

-Run winch with vehicle motor running.

-Recharge battery

-Clean, tighten, or replace battery cable

connections

Motor

overheating

-Winch running time

too long

-Allow winch to cool down periodically.

Motor runs only

in one direction

-Loose or corroded

battery cable or motor

cable connections.

-Defective

relay/switch/remote

controller assembly

-Clean, tighten, or replace battery cable

connections.

-Repair or Replace relay/switch/remote

controller assembly.

Winch braking

malfunction.

-Cable works in wrong

direction.

-Adjust the cable working direction.

-Clockwise direction looking from motor end.

-Brake slice worn or

breakdown.

-Replace with new brake.

www.tractorsupply.com For customer support call 1-888-376-9601 52

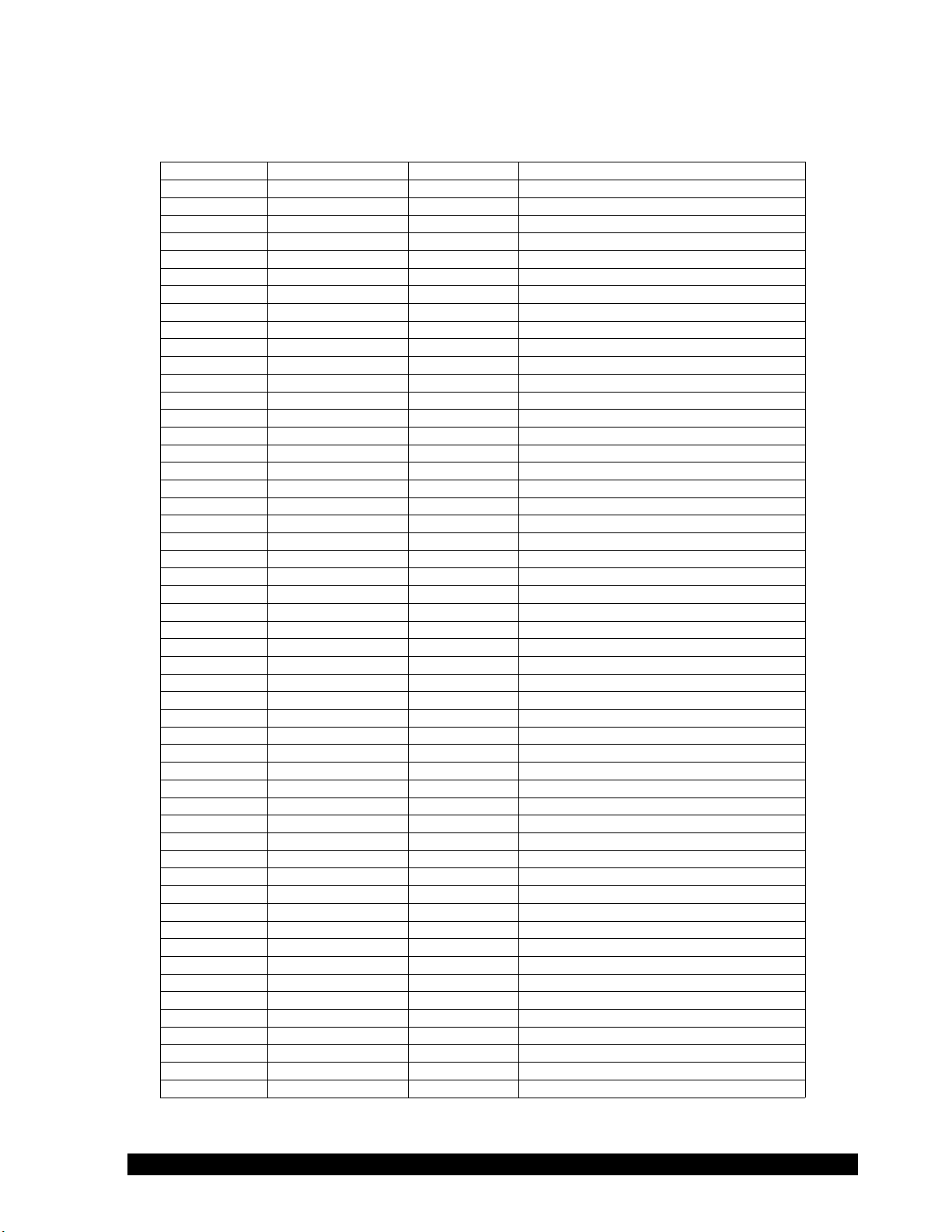

WINCH PART LIST

No.

Part #

Qty

Description

1

VT1000100

1

Motor Assembly

2

VT1000001

4

Cap Screw M10 x 35

3

VT1000002

4

Lock Washer Φ10

4

VT1000003

4

Think Flat Washer Φ10

5

VT1000004

4

Hex Nut M10

6

VT1000005

2

Bushing—Drum

7

VT1000006

2

Ring Seals

8

VT1000007

1

Tie Bar

9

VT1000008

4

Cap Screw M8 x 30

10

VT1000009

4

Lock Washer Φ8

11

VT1000011

1

Coupling

12

VT1000200

1

Drum Assembly

13

VT1000011

1

Screw M8 x 10

14

VT1000012

1

Six Angle Bar

15

VT1000013

1

Coupling

16

VT1000014

9

Screw M5 x18

17

VT1000015

9

Lock Washer Φ5

18

VT1000016

1

End Bearing

19

VT1000017

1

Gasket

20

VT1000018

1

Gear—Ring

21

VT1000019

1

Circlip For Hole

22

VT1000020

1

Bearing

23

VT1000300

1

Gear Carrier Assembly(Output)

24

VT1000400

1

Gear Carrier Assembly(Intermediate)

25

VT1000021

1

Circlip For Hole

26

VT1000500

1

Brake/ Shaft Assembly

27

VT1000022

1

Gear—Input Sun

28

VT1000023

3

Planetary Gear

29

VT1000024

1

Trust Washer

30

VT1000025

1

Bearing

31

VT1000026

1

Gear—Housing

32

VT1000027

1

Ring Seals

33

VT1000028

1

Clutch Cover

34

VT1000029

1

Clutch Shaft

35

VT1000030

1

Screw Cover

36

VT1000031

1

Clutch Handle

37

VT1000032

1

Clutch Screw

38

VT1000033

2

Cap Screw M10 x 30

39

VT1000034

1

Aluminium Fairlead

40

VT1000035

4

Think Flat Washer Φ10

41

VT1000036

2

Lock Washer Φ10

42

VT1000037

2

Hex Nut M10

43

VT1000600

1

Remote Control

44

VT1000700

1

Switch(RC8III)

45

VT1000800

1

Cable Assembly

46

VT1000900

1

Hook

47

VT1000038

1

Strap

48

VT1000039

6

Cap Screw M6 x 10

49

VT1000040

1

Motor Housing

50

VT1000041

4

Cap Screw M6 x 14

51

VT1001000

1

Control Assembly

52

VT1000042

1

Reducer Housing

www.tractorsupply.com For customer support call 1-888-376-9601 62

SAFETY PRECAUTIONS

Never lift people or hoist loads over people. Do not lift items vertically, this winch

is designed for horizontal use only.

Never overload. Be sure all equipment used meets the winch’s maximum line pull

rating. When double-lining, pulley blocks should be rated for a minimum of two

times the winch’s line pull rating.

Do not attempt prolonged pulls with heavy loads. The electric winch is designed

for intermittent use only, and should not be used in a constant duty application.

Never pull for more than one minute or exceed the rated load. If the winch motor

becomes hot to the touch, stop the winch and allow it to cool down for several

minutes.

Never operate winch with less than 5 turns of cable around the winch drum since

the cable end may not withstand full load.

Avoid continuous pulls from extreme angles because this will cause the cable to

gather on one end of the drum and damage the cable. Be aware that the winch’s

line pull capacity is the max line pull of the first layer. Never operate winch pulling

a load that exceeds the rated capacity.

Never hook the cable back to itself because it could damage the cable.

Be sure the winch is mounted securely on the vehicle or bracket before operation.

Before moving a load, inspect the cable. Prevent kinks and uneven cable layer

before they occur. Apply proper tension to loads under 100lbs.

Do not move your vehicle to assist the winch in pulling the load. It will be easy to

overload, and cause cable damage. Be aware of the danger zone. Keep away

from the danger zone during the operation. The danger zone is the area of the

winch drum, the fairlead (if fitted), the cable, the pulley block (if used), the hook,

and the motor.

Never approach or span the cable when the winch is under load.

When using the winch to move a load, place the vehicle transmission in neutral,

set vehicle brake, and chock all wheels. The vehicle engine should be running

during winch operation so that battery has fully electricity. Never use the winch

when there is a lack of voltage.

Never disconnect free spool cultch when there is a load on the winch.

Always stand clear of the cable, hook and winch. You should disconnect the clutch

first, then use the hand saver bar to hitch the hook to pull the cable.

Inspect winch, cable, hooks and other accessories frequently. A frayed cable with

broken strands should be replaced immediately. Use heavy leather gloves when

handling the cable. Do not let the cable slide through your hands. Inspect the

cable before use. Mashed , pinched, frayed or kinked areas severely reduce the

load-carrying capability. Replacement cables must be re-spooled under 100lbs.

To keep stated tensile, re-spool the cable around the drum tightly after operation.

Do not operate winch when under the influence of drugs, alcohol or medication.

Always stay alert during operation.

Wear eye protection and personal protective equipment while operating winch.

For loads over 50% of rated line pull, the use of the pulley block/snatch block to

double the cable is recommended.

Do not operate around potentially flammable liquids, gases, or debris. Sparks

may occur, resulting in the ignition of fire.

Tractor Supply Company ○

R0

www.tractorsupply.com For customer support call 1-888-376-9601 0

Line speed and Motor current(First layer)

Line Pull

Line Speed

ft./min (m/min)

Motor Current

Amps

Ibs.(kgs)

12V DC

12V DC

0(0)

29.5(9.0)

60

4000(1814)

12.1(3.7)

180

7000(3175)

9.2(2.8)

270

10000(4536)

5.25(1.6)

350

Line Pull And Cable Capacity

Layer

Rated line pull lbs (kgs)

Total rope on the drum ft (m)

1

10000(4536)

17.4(5.3)

2

7848(3560)

39.4(12.0)

3

6459(2930)

65.0(19.8)

4

5487(2489)

82.0(25.0)

Distributed By:

TRACTOR SUPPLY COMPANY

5401 VIRGINIA WAY,

BRENTWOOD, TN37027

For customer support, call:1-888-376-9601

www.TractorSupply.com

MADE IN CHINA

Table of contents

Popular Winch manuals by other brands

HADEF

HADEF 260/23 Installation, Operating and Maintenance Instruction

Harken

Harken 60.2STEC Installation and maintenance manual

Motoalliance

Motoalliance Midnight Series Installation and operation manual

VersaChock

VersaChock Davit owner's manual

Quadratec

Quadratec Q11000s Operator's guide

Harken

Harken HC9565.CLEAR User instruction manual

IKAR

IKAR PLW Log book and instructions for use

Fieryred

Fieryred WIN14500R-ROPE user manual

BRADEN

BRADEN PD18C Installation maintenance and service manual

Paccar

Paccar Braden BP200 Installation maintenance and service manual

Tulsa

Tulsa RUFNEK 15 Service manual

Andersen

Andersen WINCH 40 Mounting instruction