UNIT PROTECTION

It is your responsibility to maintain the correct chemical balance in your pool

and spa water. Improper or inconsistent chemical maintenance could cause

damage to your pool/spa equipment, pool surface or lining, pool heater and

also could be harmful to your health. Here are a few tips to avoid these prob-

lems.

Install any chlorinating devise down stream of heater with a check valve and

plumbing loop between the heater and the chlorinator.

DO NOT inject chlorine gas into your pool or spa.

DO NOT use floating chlorine tablet feeders.

DO NOT put solid chlorine tablets in the skimmer.

Maintain a consistent, chemically - balanced pool. Depriving a pool of chemi-

cals, then shocking it with heavy chemicals is an incorrect and sometimes

damaging practice when performed too often. This is common for homeowners

who are out of town for extended periods of time .

If the heat exchanger in the unit is deprived of water for several days, high

chlorine gas could cause excessive corrosion. Even if power to the unit is

turned off, be sure that water can still circulate through the unit at all times,

especially during the summer months when no heat is required.

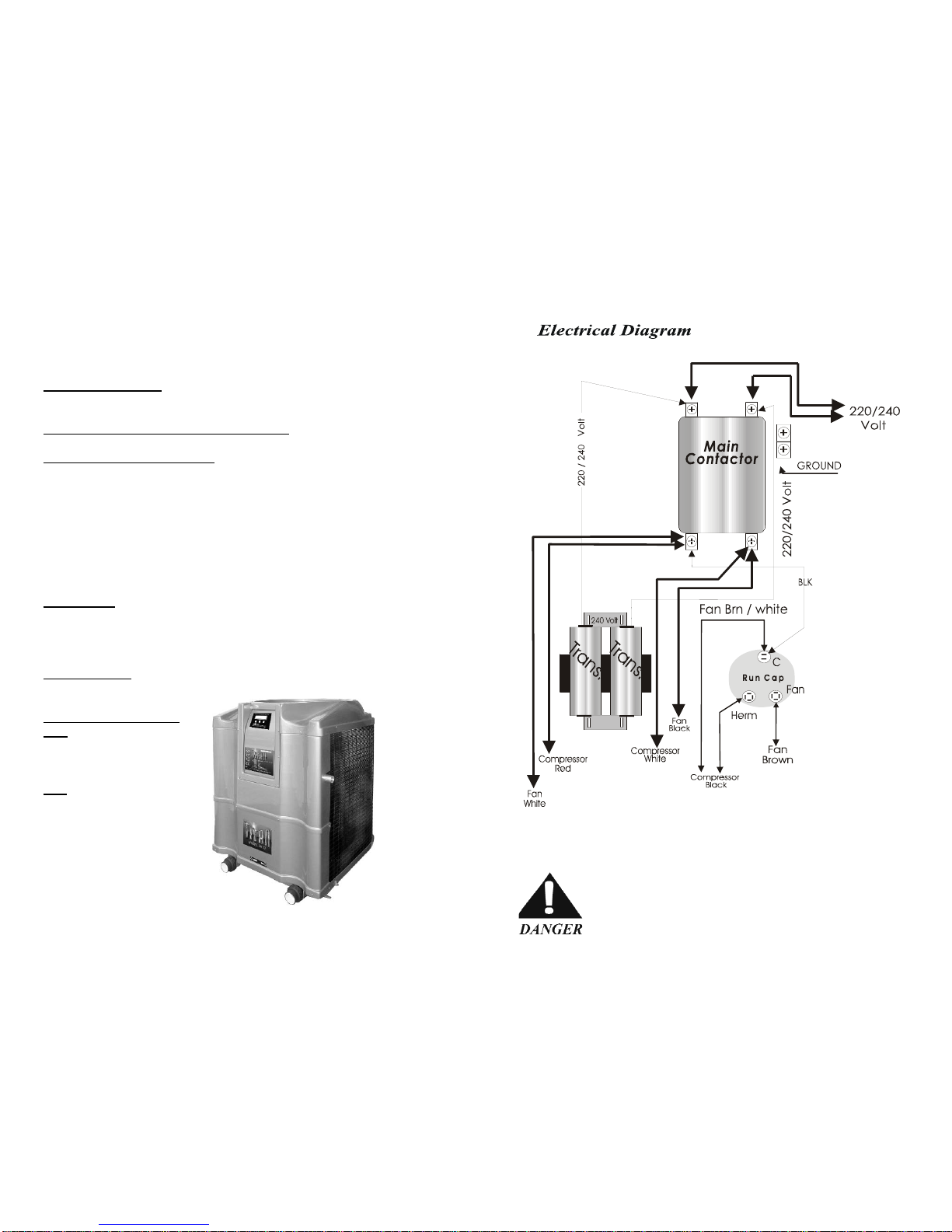

Make sure your unit is electrically bonded, as described in the electrical section

of this manual. This will help prevent electrolysis, which could damage the heat

exchanger in your pool heater.

The following are recommended water quality readings. These readings should

be maintained at all times to ensure good health while protecting your pool

Note- Damage due to abusive water chemistry or electrolysis is not covered under war-

ranty. Please have your water checked regularly by a pool professional.

PH Level 7.2-7.8

Total Alkalinity 80-100 PPM (parts per million)

Total Dissolved Solids - below 1200 PPM

Chlorine Concentration (free) 1.0- 2.0 PPM

WINTERIZING YOUR POOL HEATER

During a short term freeze, run your circulating pump continuously to prevent

damage to your filter, pump and pool heaters.

During a long-term hard freeze, disconnect the unions on the heater and

remove all the water from the heat exchanger to prevent the pipes from burst-

ing.

In addition to loosening the unions on the heater, please find the heat exchang-

er drain fitting located on the bottom right hand side of the heater. Push in the

gray retainer ring while pulling out the gray plug. Once drained simply push

the plug back into the drain fitting.

Note- Freeze damage is not covered by warranty so please take every precaution during

freezing conditions.

UNIT MAINTENANCE

Your Kopec pool heater is basically maintenance free!

Keep the condensation drain fitting free of any leaves or debris.

Hose off any debris that may be in the evaporator fins to ensure good airflow.

Clean plastic cabinet occasionally to maintain the bright shiny color

PERFORMANCE EFFECTING FACTORS

It is very important to understand that heat pump pool heaters are designed to

maintain temperature and do not heat quickly. Initial heat up time could be as

much as 24-48 hours, because it is necessary to heat the concrete walls in the

pool, as well as the water. Once your desired temperature is reached, the heat

pump will maintain the temperature, providing the circulating pump run time is

adequate, depending on temperature desired, size of pool and outside weather

conditions. Listed below are a few factors to consider when evaluating your

unit’s performance.

P-16 P-17