Assembly, use and maintenance manual 10

CHAPTER 2

IDENTIFICATION AND CONTROL OF THE MATERIAL

1.1 PREAMBLE

Each shipment of dock shelters is made of one or more packages, in case of multi-

ple orders, already placed on pallets. Max size for each package is mm 1.100 x 3.600

x height 1.300. Each package can reach max 800 kgs.

Material contained in the packages is wrapped in plastic sheets.

All packages have a label carrying the order number.

In case of supply and delivery of more than one dock shelter it could happen to have

the coverings all in one package. uts, bolts and elastic strings can also be packed

all together in one package.

To verify the completeness of the supply we suggest to check all the packages.

If packages are to be stored, the warehouse must be sheltered and dry. Packages

must not be placed one on top of the other in order to avoid damages. Take care not

to damage the PVC fabric when cutting the plastic wrappings.

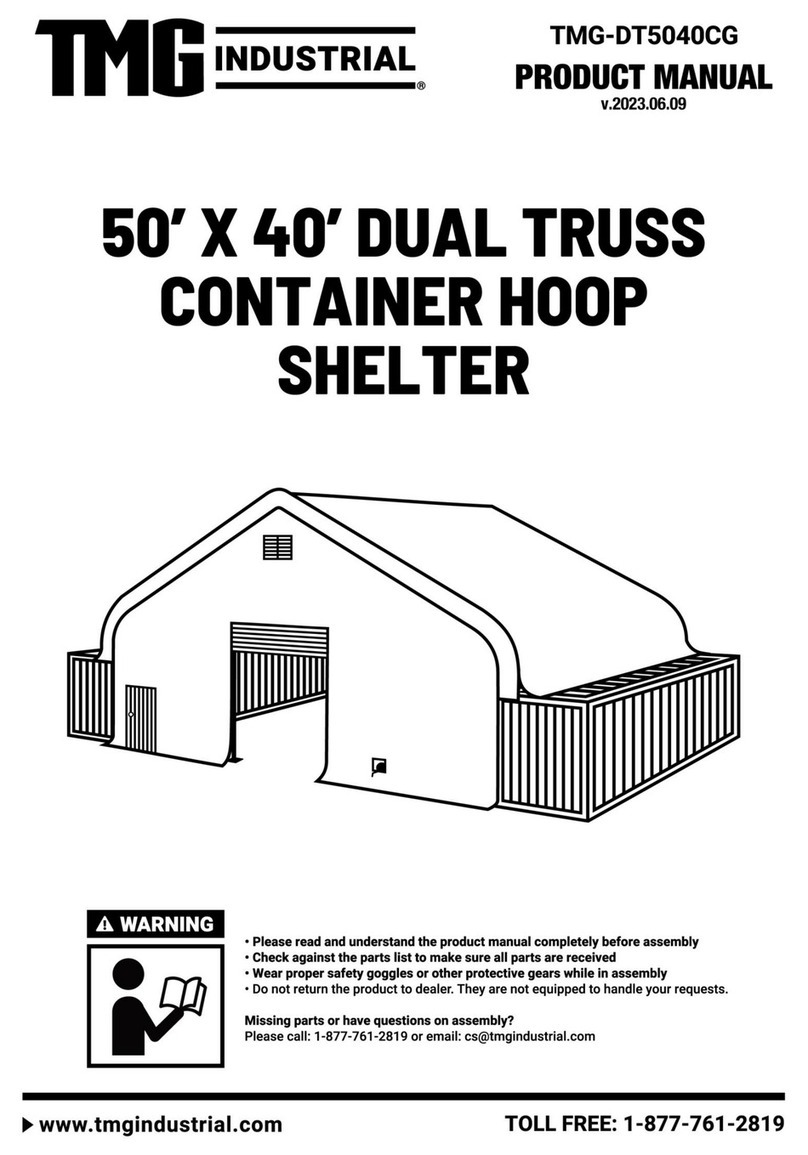

1.2 IDENTIFICATION AND CONTROL OF THE MATERIAL

Transport documents accompanying the delivery of the dock shelter also include a

packing list detailing the number of bolts, drilling screws necessary for assembly plus

dowels to fix the dock to the wall.

Upon receipt the material must go through inspection with the aid of the packing list

to verify completeness. In case of damages or missing items, written claim must be

made within seven days from delivery and sent through registered mail to Kopron

S.p.A. See drawing enclosed to better identify the details listed in the packing list.

IDENTIFICATION AND CONTROL OF THE MATERIAL