Assembly, use and maintenance manual

4

INT ODUCTION

UNIT I - DESC IPTION

CHAP. 1

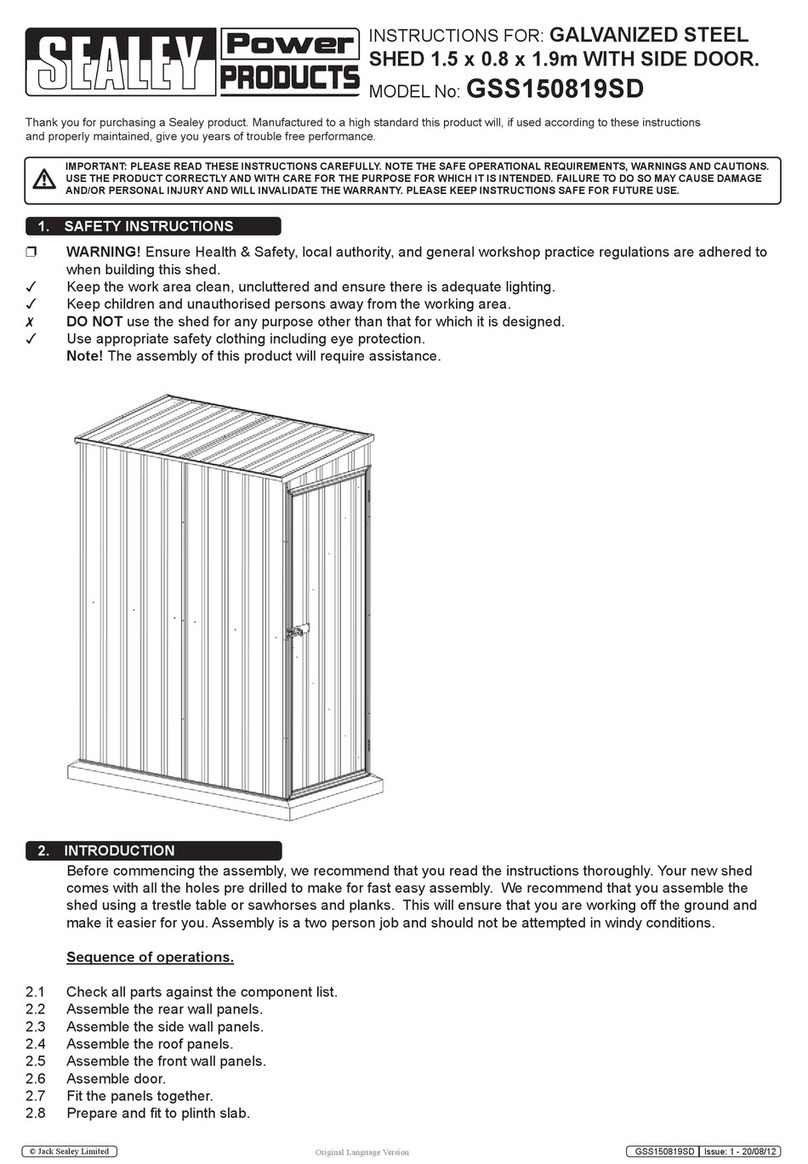

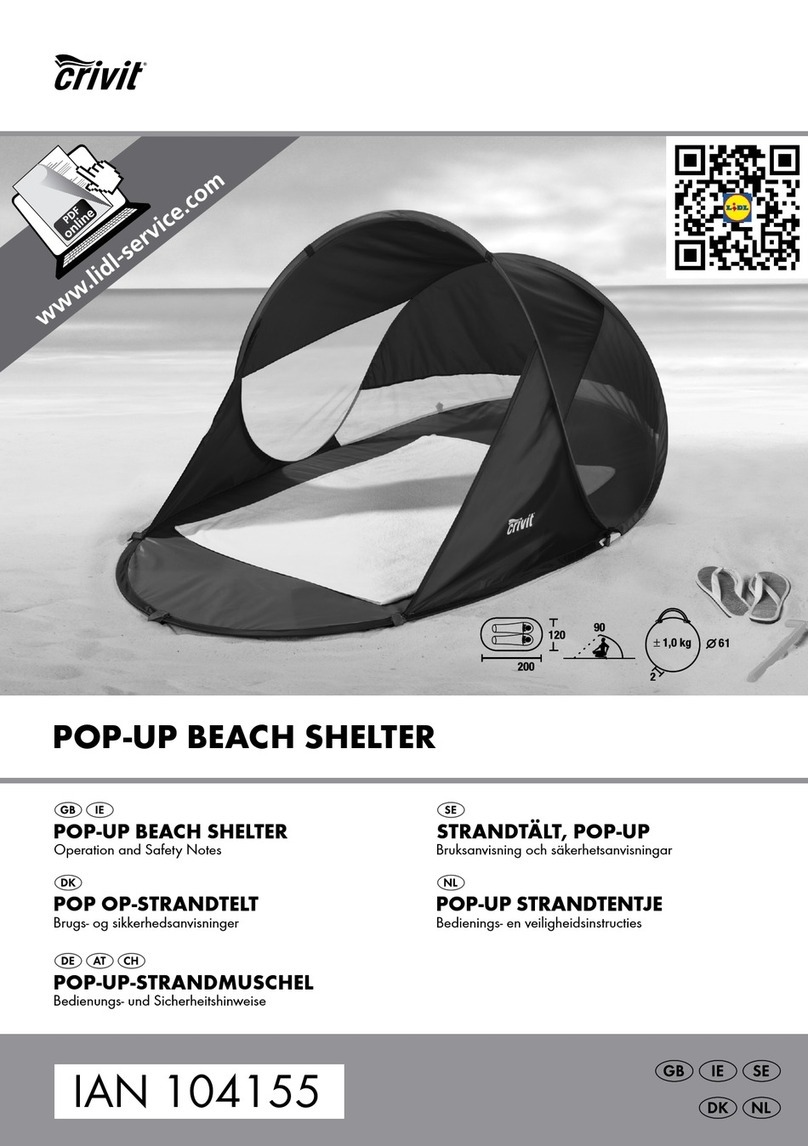

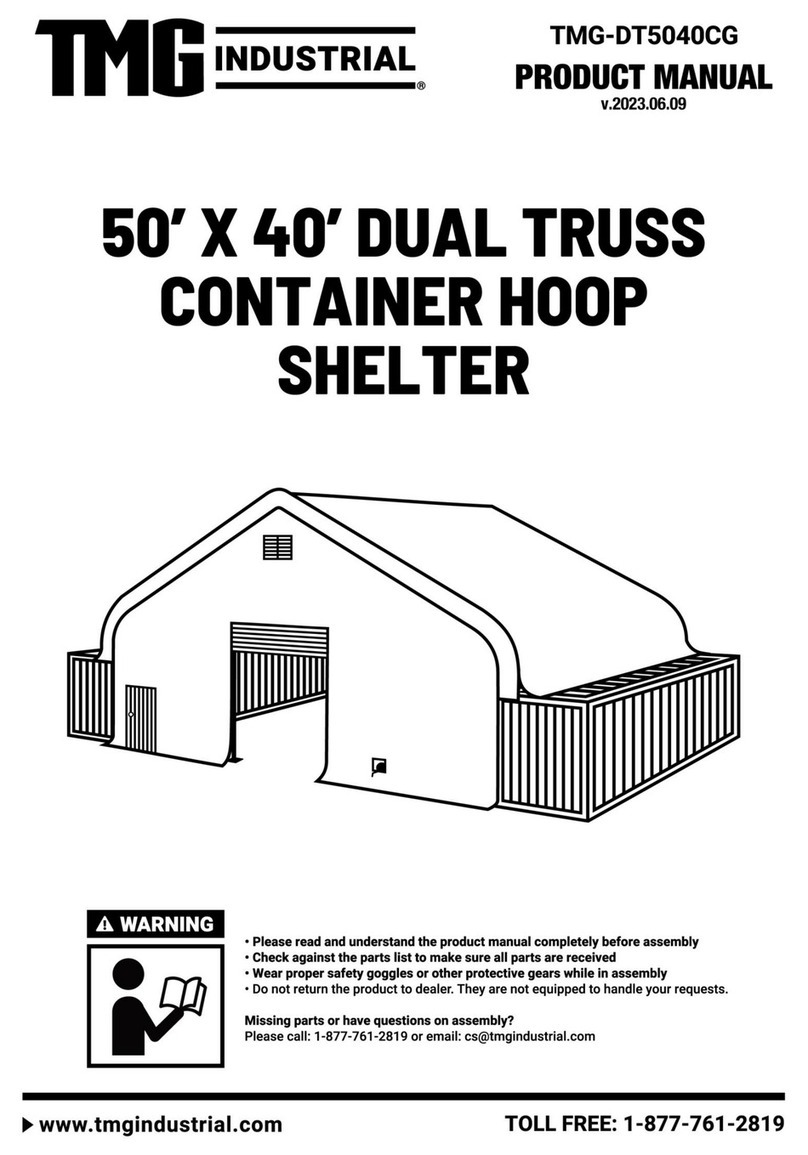

1.1 DESC IPTION OF AISED DOCK SHELTE S

1.2 IMP OPE USE

1.3 IDENTIFICATION PLATE

UNIT II -IDENTIFICATION AND CONT OL OF THE MATE IAL

CHAP. 1

1.1 P EAMBLE

1.2 IDENTIFICATION AND CONT OL OF THE MATE IAL

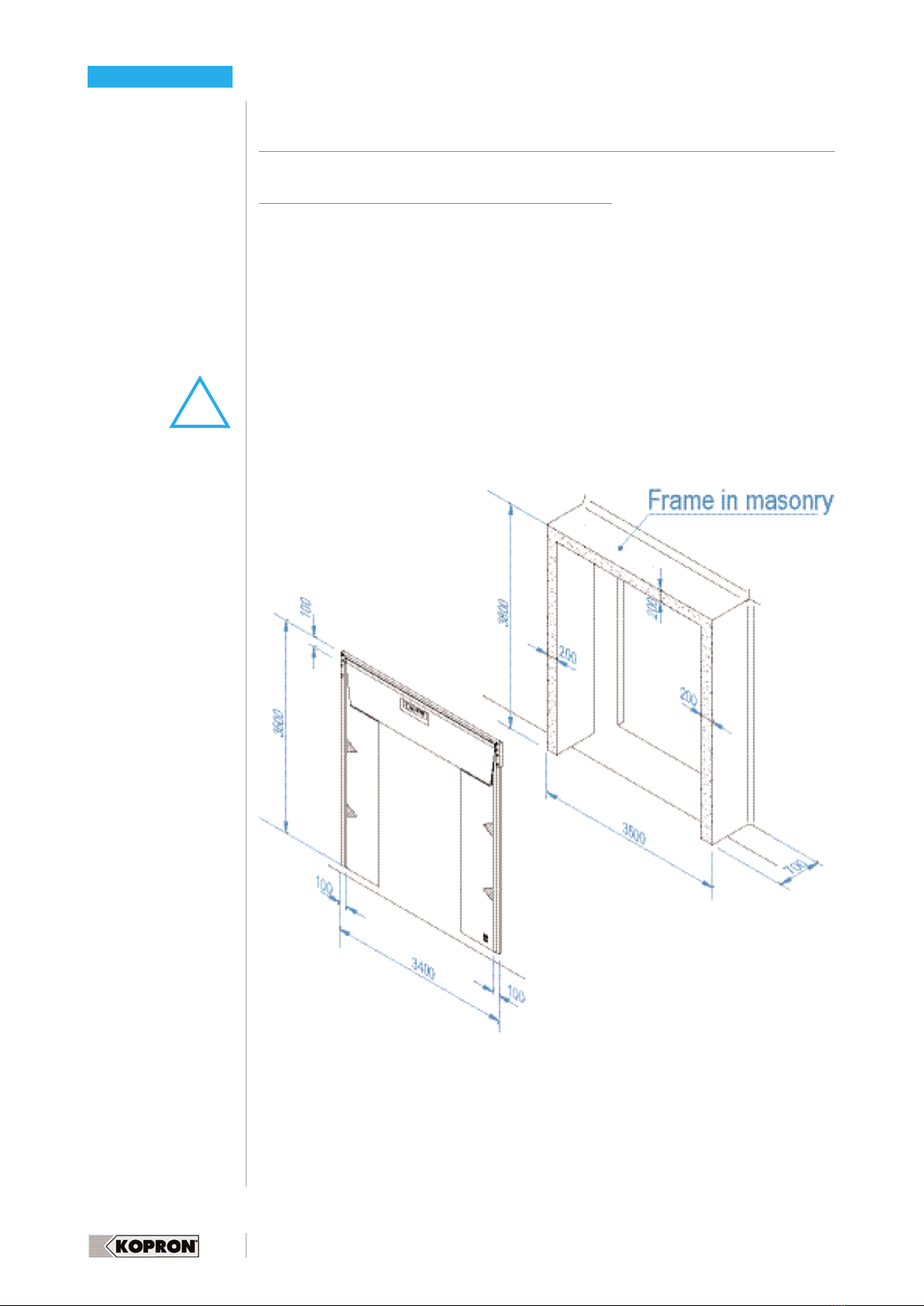

UNIT III - VE IFICATION OF THE MASON Y WO K

CHAP. 1

1.1 VE IFICATION OF THE MASON Y WO K

UNIT IV - INST UCTIONS

CHAP. 1- INST UCTIONS FO T ANSPO T

1.1 GENE AL INDICATIONS

1.2 HANDLING INST UCTIONS

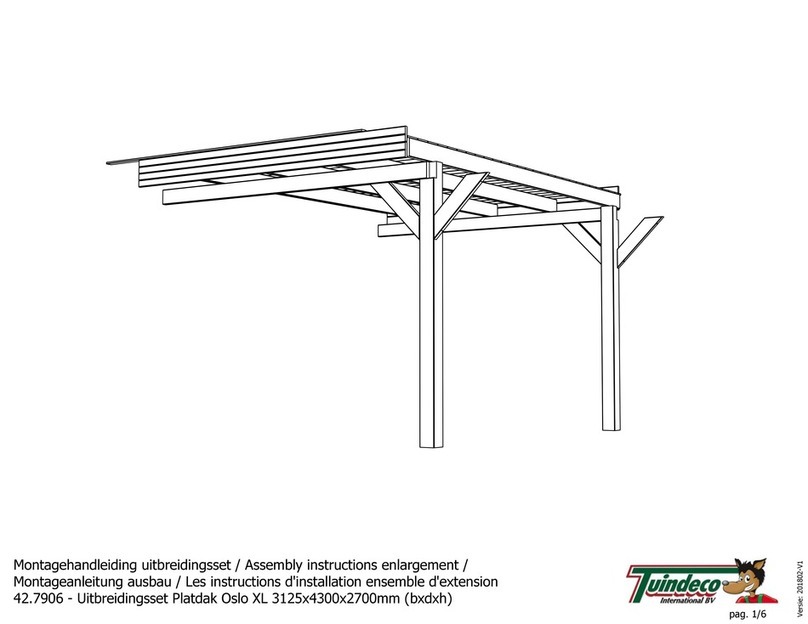

CHAP. 2 – INSTALLATION

2.1 BEFO E STA TING

2.2 F ONT SEAL ASSEMBLY

2.3 POSITIONING AND FIXING

2.3.1 NOTE ON THE USE OF THE ANCHO BOLTS

2.4.ASSEMBLY OF THE ELASTIC CO D

2.5 LIST OF TOOLS AND EQUIPMENT

2.6 EMOVAL OF EXCEEDING MATE IAL

2.7 ENVI ONMENT CONDITIONS

CHAP. 3 - USE

3.1 ISKS AND P OTECTION

3.2 FI E P EVENTION

CHAP. 4 - ANOMALIES, MAINTENANCE AND EPAI

4 1 P EVENTIVE MAINITENANCE AND PLANNED INSPECTIONS

4.2 NOTES ON THE EQUIPMENT TO USE

CHAP. 5 - INST UCTIONS ON SAFETY

5.1 OTHE ISKS

5.2 MAINTENANCE INST UCTIONS

UNIT V -ENVI ONMENT POLLUTION

CHAP. 1 -

1.1 DISPOSAL AND DISMANTELLING

UNIT VI - SPA E PA TS

CHAP. 1 –

1.1 SPA E PA TS.

UNIT VII – SE VICE / GUA ANTEE

CHAP. 1

1.1 P OCEDU ES TO EQUEST ASSISTANCE

1.2 TE MS AND CONDITIONS FO INTE VENTIONS UNDE GUA ANTEE

All drawings and technical characteristics may be subject to changes at any time,

should this occur we shall provide to update the manual as soon as possible.

Kopron S.p.A.

page 5

7

8

8

9

9

11

12

12

13

14

15

17

18

19

19

19

20

20

21

21

22

23

24

24

26

27

S MMARY