X

●If not, it may cause fire,

electric shock or the

machine malfunction

4

●There is a risk of fire or electric

shock. It may also cause the

machine malfunction

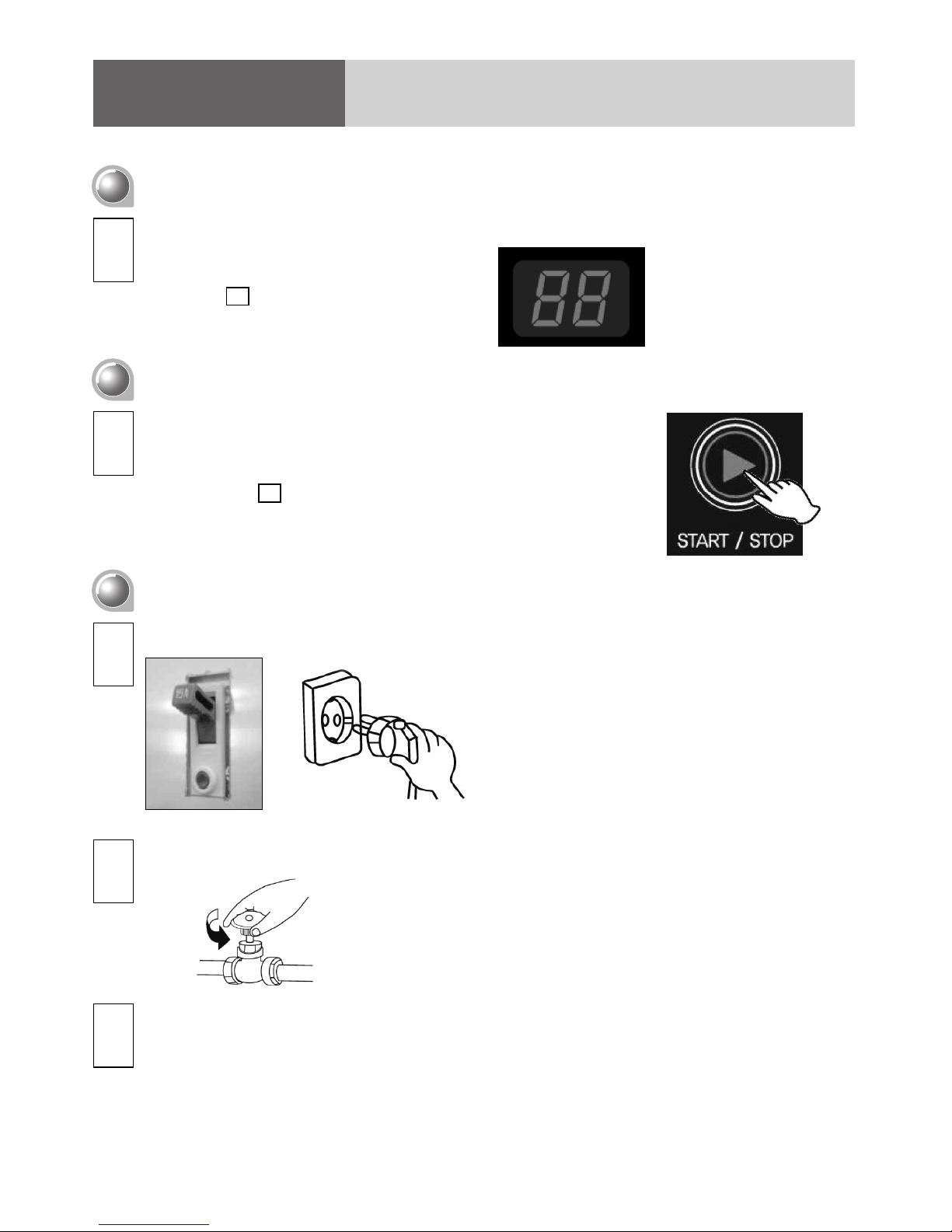

●

It may cause bad quality

or odor of the

water for ice

making)

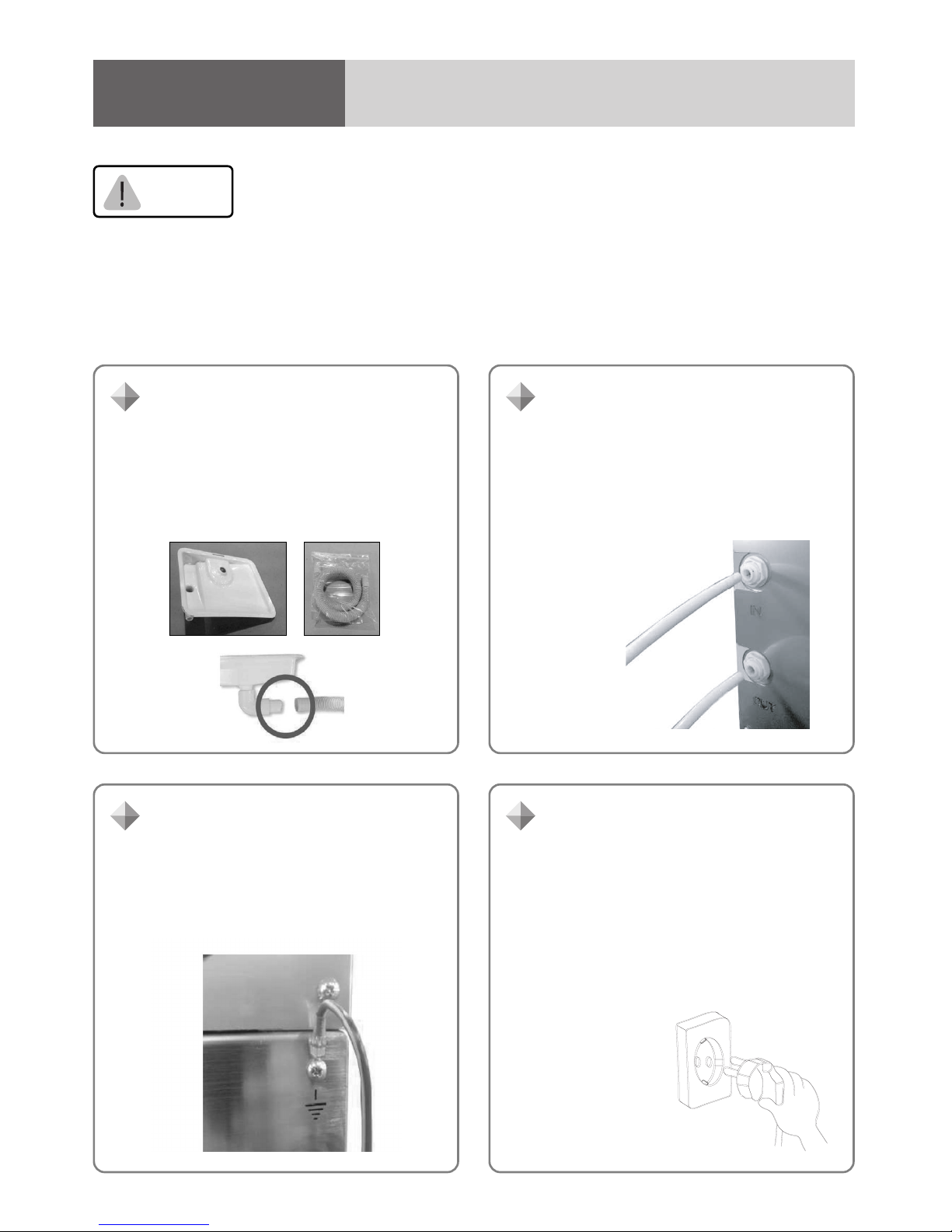

●If water in cooling water coil and pressure valve is

frozen, there may be freezing-burst

●

If not, please remove water in cooling coil and then store it

●

In case of out of temperature

degrees, it may cause damages

or malfunctions

●

Depending on temperature or

humidity, amount of ice making

can be different

●

If water pressure is higher than

6 bar, please install pressure

decrease device

●

When it is less than recommended

pressure, please install pressure

pump. Please contact to the service

center(pressure pump is an option.)

●Please keep balance

between front and back

and right and left within

2mm. (It may cause

uneven ice quality)

●If drainage is not well done,

water will overflow or standing

water may cause unhealthy use

No thinner,

organic agent,

petrol or gas

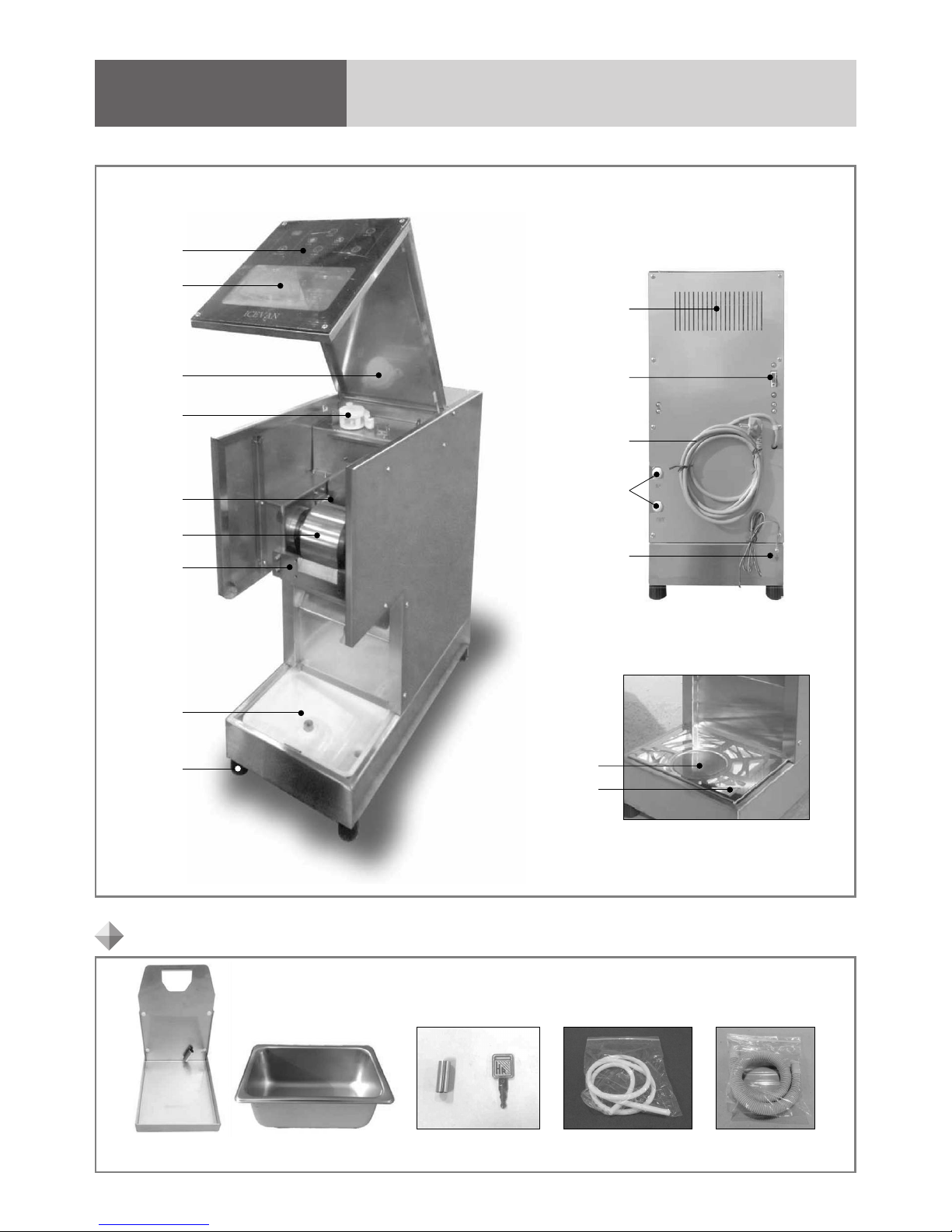

Ice making dish

Drainage dish

Material supply hose

Ice making

material container

Over 10℃

Less than 6bar

1

Preparation