4

Ice making dishLow ice container material hose

Ice making material container

Over 10℃

1

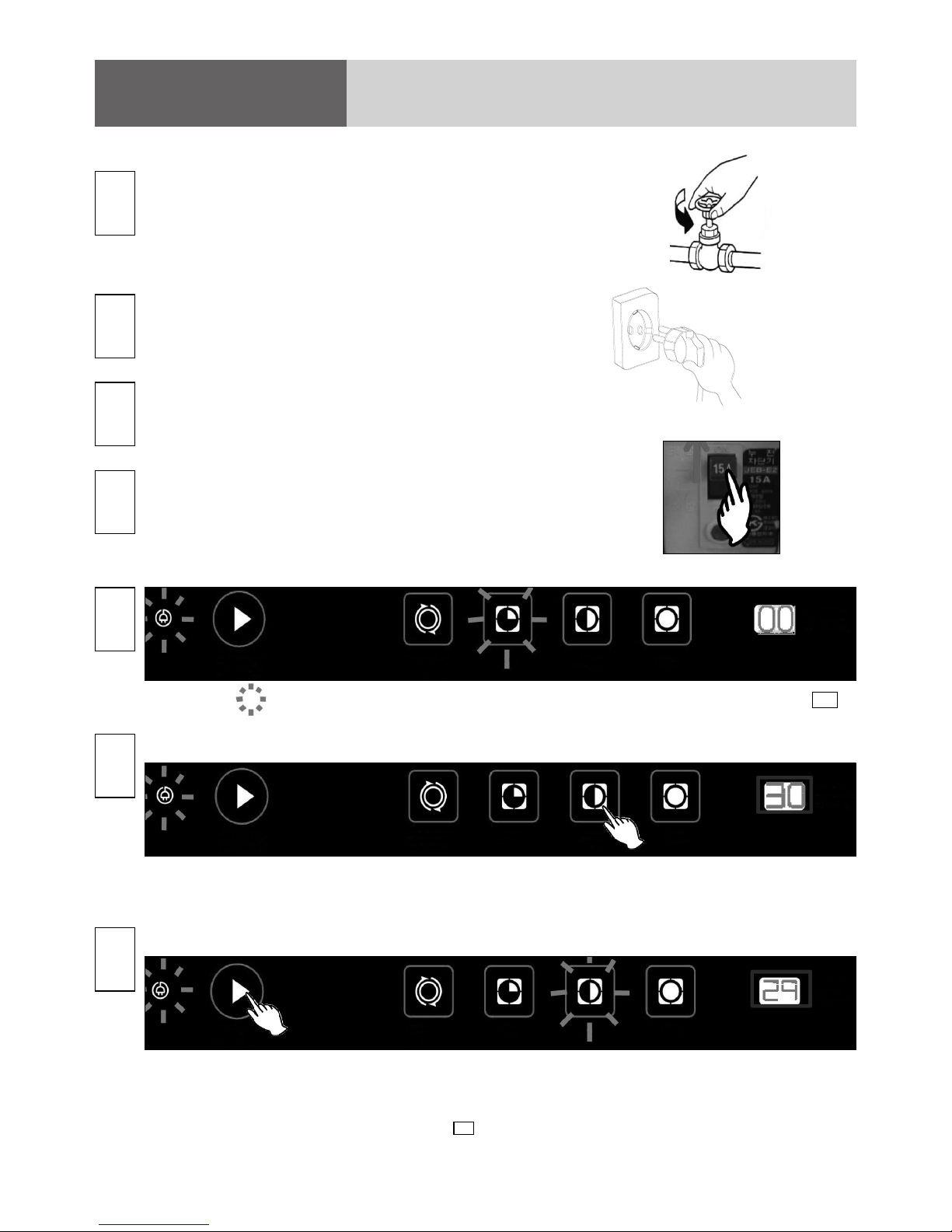

Preparation

●If not, it may cause fire,

electric shock or the

machine malfunction

X

●There is a risk of fire or electric

shock. It may also cause the

product malfunction

No thinner,

organic agent,

petrol or gas

●

It may cause bad quality or odor of the water for ice making

●If water in cooling water coil and pressure valve is

frozen, there may be freezing-burst

●

If not, please remove water in cooling coil and then store it

●

In case of out of temperature

degrees, it may cause damages

or malfunctions

●

Depending on temperature or

humidity, amount of ice making

can be different

●

If water pressure is higher than

6 bar, please install pressure

decrease device

●

When it is less than recommended

pressure, please install pressure

pump. Please contact to the service

center(pressure pump is an option.)

Less than 6bar

●Please keep balance

between front and back

and right and left within

2mm. (It may cause

uneven ice quality)

●If drainage is not well done,

water will overflow or standing

water may cause unhealthy use