Introduction

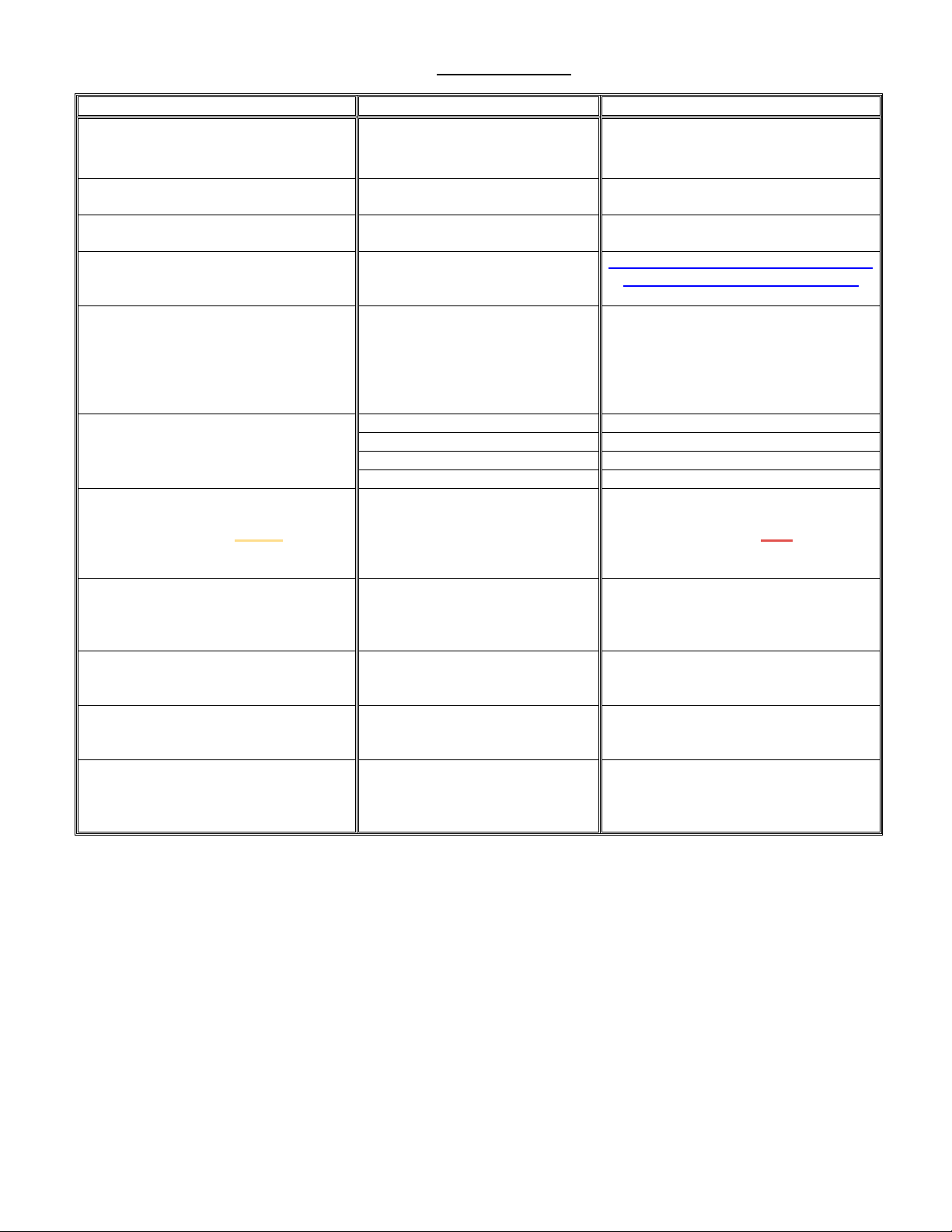

Thank you for selecting The Alloy Scout (Part No. 1545) Stainless Steel Identification Kit. This rapid

spot test kit precisely determines the presence of three common elements alloyed in stainless steels:

chromium, nickel, and molybdenum. It is especially effective at sorting between non-stainless, SS 304,

and SS 316. If the formulated test paper turns a prescribed color, the results are positive for the

corresponding element. No other element will interfere or produce the prescribed color reaction. Spot

tests are easier, faster, and cheaper than chemical analysis in sorting stainless steel scrap or inspecting

upcoming and outgoing stock.https://youtu.be/d-C7DDK7SJI

Use this kit with the utmost confidence. It is an ASTM approved method. The Scout is the first bottle-

free chemical spot test kit. Koslow’s patented Dry-Spot Technology utilizes age-old and acceptable

chemical methods but eliminates the need for bottles of solutions. Instead, cartridges dispense very

small controlled quantities of color reacting reagents.

ASTM 1476-95 is the standard guide for metals identification, grade verification, and sorting.

The Scout kit includes a small metal standard of stainless steel 316 to be used as a testing reference.

Working side by side with a known sample will show what a positive result looks like before attempting

tests on lesser-known materials. It also assures the user that the equipment and procedures are

working as they should.

The Alloy Scout (Part No. 1545) is designed to be used by inspectors, stainless steel fabricators,

process and quality control engineers, and other finishing technicians are working in applications where

verifying the grade of stainless steel is critical. With colorful results, non-technical personnel can easily

inspect parts as part of a routine quality control program. This kit can be used on many types of metal

surfaces: large tanks, pipes, welded areas, wire, and even small parts (1 sq. cm.).

Read this manual before operating your kit. This manual functions in two ways, firstly as a step by step

guide to help the user operate the instrument and secondly as a handy reference guide. This instruction

manual is written to cover as many anticipated questions as possible concerning the Alloy Scout. If

there are any doubts about the use of this tester, do not hesitate to contact a Koslow Technical Support

Representative at 011 (201) 541-9100. We want you to be happy and satisfied with your results.

Safe Handling

•We care about you. Please always wear safety equipment when using Koslow products.

•In handling any chemical, good industrial hygiene practices are imperative.

•Internal kit parts may be hazardous. Caution should be exercised in kit use.

•Use industrial Personal Protection Equipment (P.P.E.) such as gloves and eye protection.

•Use the wrist strap lanyard to prevent dropping the probe in sensitive areas.

•Work outside or in a well-ventilated area. Never work in a confined space; some vapors can be

irritating.

•Wash hands after kit use and before eating.

•Do not perform tests on energized equipment. Remove from power before metal testing.

•For general industrial safety and cleanliness, conclude test by wiping the tested metal surface

with a soft, damp cloth to remove any residual solutions. The user should then clean, condition

or sterilize as required for the intended final application.

•Only use the Scout Kit for metal testing purposes; consistent with instructions.

•Dispose of kit contents according to local regulations.

•Review all pictograms and other safety documents.