3

Cobra Tester User Manual © Copyright 2021

Introduction

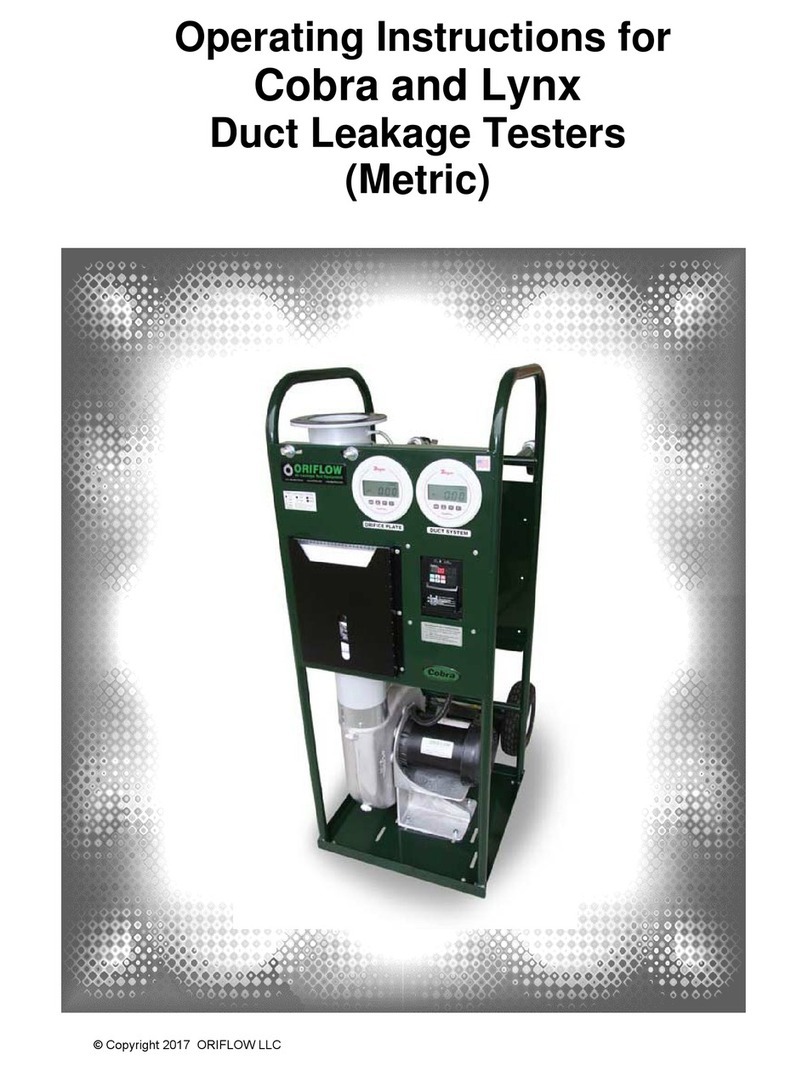

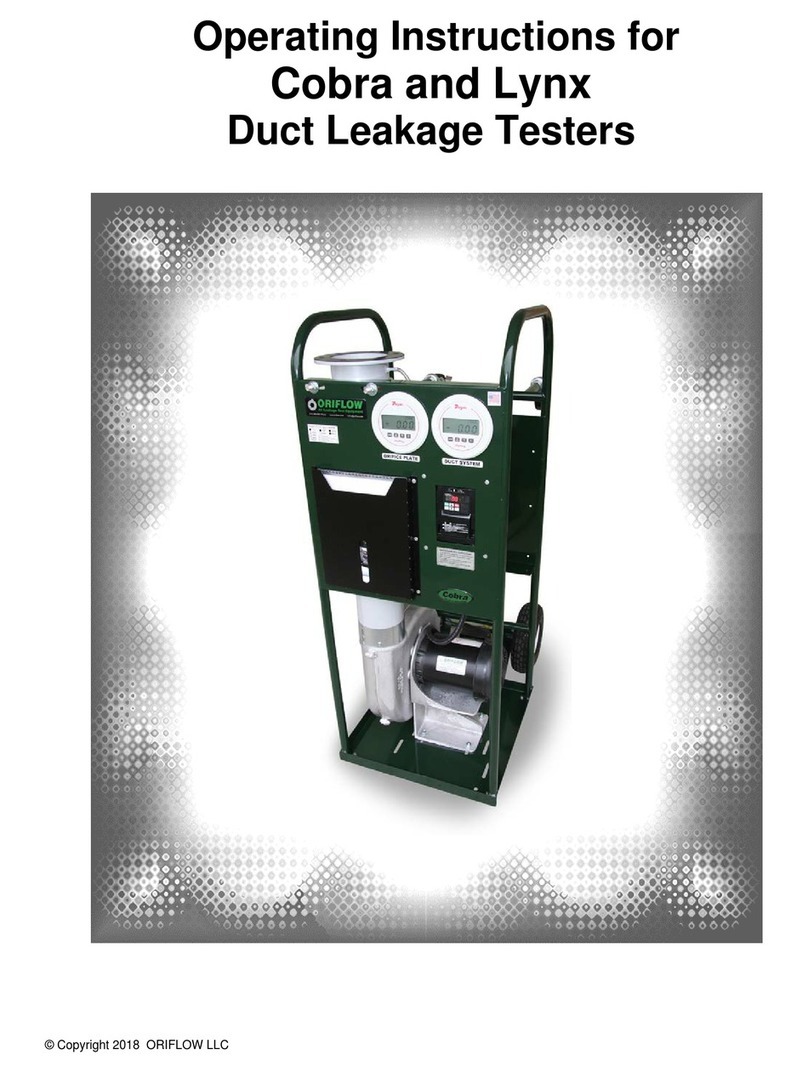

The COBRA duct leakage tester is the most widely used tester in the U.S. It is the simplest to

use tester on the market backed by unparalleled customer service and technical support. Call

us, find out.

The recommended recalibration interval for the plates is 5 years. Note the authority having

jurisdiction may override this requirement, and if so, Oriflow has reasonable rates for re-

calibrating orifice plates manufactured by Oriflow. Call us at 727-400-4881 to receive lead

time and pricing for calibration. After you order the calibration, just ship the two orifice tube

sections along with the Oriflow orifice plates to:

Oriflow Calibrations

2125 Range Rd., Suite B

Clearwater, Florida 33765

Safety Precautions

Before operating your tester, read the following safety precautions:

✓DO NOT operate the tester outdoors, in the rain, or where it will get wet,

✓DO NOT operate the tester while it is near or in water,

✓DO NOT operate the tester with a damaged electrical cord or plug,

✓DO NOT operate the tester without an inlet safety screen,

✓DO NOT put fingers, hands or any object near inlet of blower while it is running,

✓DO NOT touch the blower wheel when the unit is plugged in,

✓DO NOT look into the discharge end of the tester when the unit is plugged in,

✓DO NOT use the tester as a ladder or step stool,

✓DO NOT allow children near the tester,

Things you SHOULD DO:

✓Use an extension cord of the proper gauge (see Table 3 on page 5),

✓Make sure unit is electrically grounded,

✓Use the proper voltage and phase listed on the Voltage/Phase/Hz label (front panel),

✓Lock the casters when the tester is positioned horizontally,

✓Use the tester on level ground,

✓Secure the tester when transporting it,

✓Wear proper hearing protection, safety glasses and work gloves,

✓Seek assistance when lifting the tester (e.g., loading onto truck, going up or down

stairs).