7

EN-102B_f.1296

Heating and DHW mode with the heat pump switched off

When the outdoor temperature drops below the set shut-down temperature value,

the heat pump is automatically turned off and cannot produce heating water. In this

case, the heating and DHW mode is automatically performed by the additional electric

heater of the indoor unit.

Automatic defrost

Defrosting of the evaporator surface is done by reversing the refrigerant's circulation.

During the defrosting process the compressed gas is discharged from the compressor

to the evaporator, which melts the existing frost. The heating system cools down

slightly during this time. Duration the defrosting process depends on the degree of

frosting and the current external temperature. Active defrosting process is signaled

on the control panel by the icon .

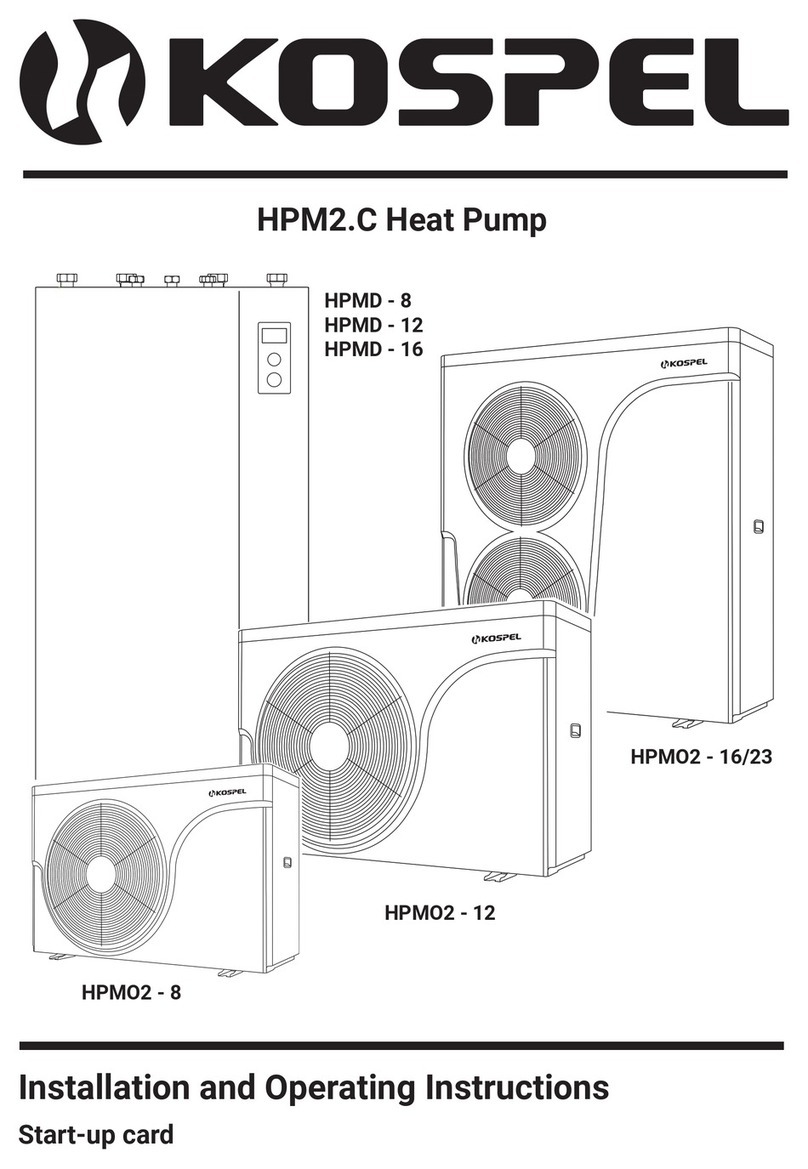

Transport and storage

The HPMO heat pump should be transported and stored in a horizontal position.

Assembly

The heat pump is designed for outdoor installation and connection to indoor hydraulic

module with integrated additional electric heater. The device must be placed on a solid,

level base or foundation concrete. For fastening, use the attached vibration isolators.

To protect the device against snow and excessive moisture, base or the foundation

should protrude around 300mm above the ground level.

Prepare the ground under the foundation for free drainage of the condensate from

the drip tray. Drainage should be below the freezing zone. The layer thickness and

level must comply with local requirements and principles of construction technique.

The hole diameter should not be less than 100mm.

Condensate drain pipe should be thermally insulated. Thorough leveling the HPMO

outdoor unit will allow for free drainage of the condensate from the drip tray.

The heat pump should not be placed against the wall of rooms where noise could

interfere; e.g. by the bedroom wall. In order to maintain the high eciency of device it

is necessary to keep minimum distance against building's walls and other obstacles.

Restriction of the air ow can lead to the intake of cooled (heated in cooling mode)

air and lead to an increase in energy consumption of the compressor.

Connect the heating medium pipes to the heat pump and hydraulic module.