10

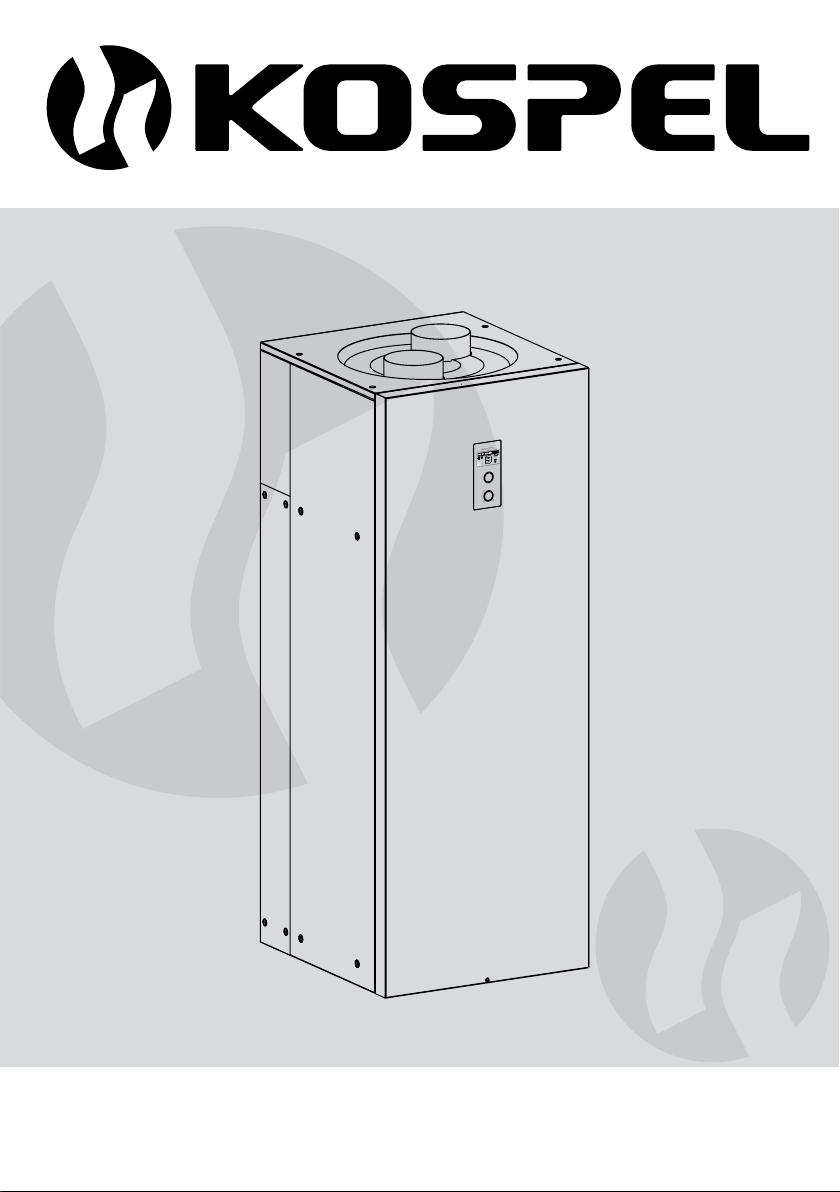

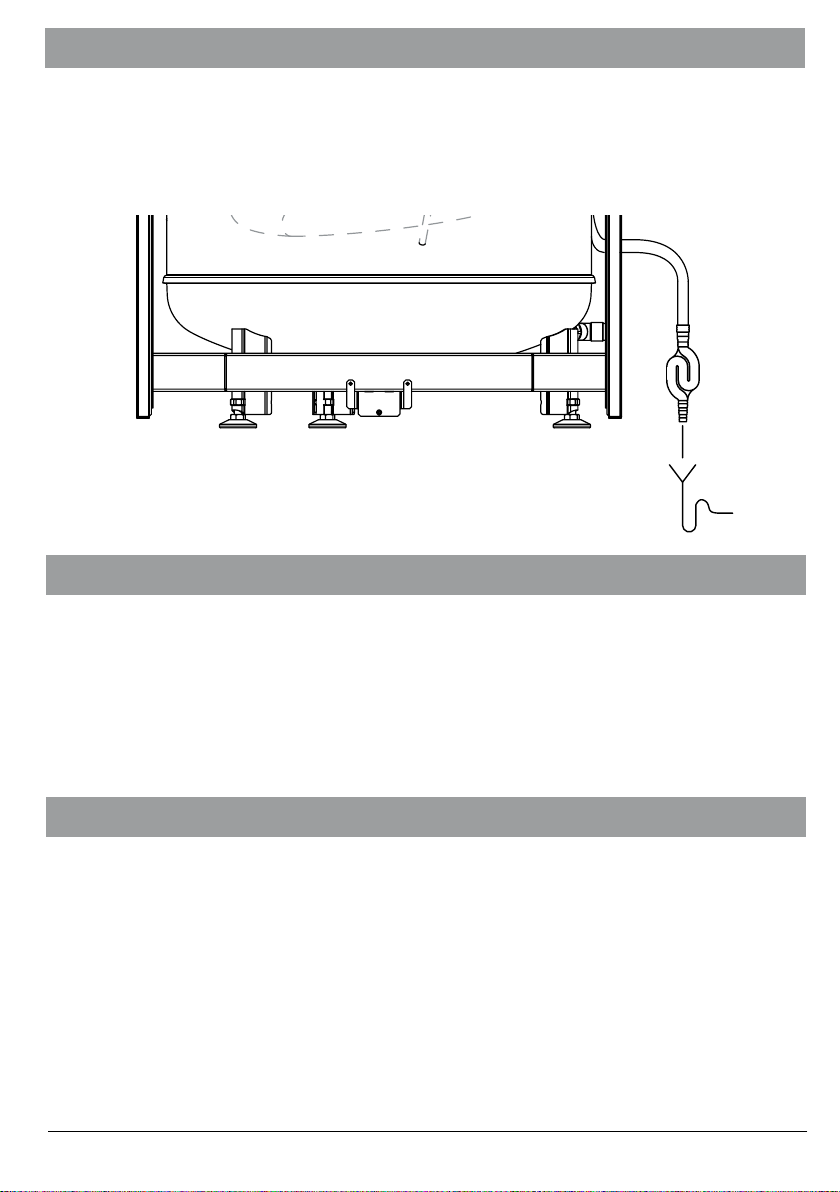

Operation of control panel

Use the lower knob to select operating mode

[3]:

- stand-by > heating pump is off, only

frost protection is active,

- compressor > according to congured

work schedule heat pump maintains

set hot water temperature if the air

temperature intake does not allow to

activate compressor, occasionally the

conditions of starting heat pump will be

veried,

- compressor + additional heat source>

according to congured work schedule heat

pump maintains set hot water temperature,

if the air temperature intake will not allow to

activate compressor additional heat source

is activated and occasionally the conditions

of starting heat pump will be veried,

- compressor + additional heat source

+ heater > according to congured work

schedule heat pump and external heat

source maintain set hot water temperature,

if the air temperature intake will not allow to

activate compressor heater is activated and

occasionally the conditions of starting heat

pump will be veried,

- additional heat source > according

to congured work schedule additional

heat source maintains set hot water

temperature,

-

turbo > selecting this mode enables

heating water with all available

heat sources until reaching the set

temperature,and returns to the previous

work mode except stand-by mode. In

[1] - display

[2] - preview and settings navigation

dial

[3] - mode dial

2

3

1

9:37 TUE 2.01.2018

17

°

41

°

12.7°

Tzad

50°

order to activate the mode enter required hot water temperature, then default

temperature of 50°C will be displayed. The temperature level can be corrected

using upper dial and then conrmed by pressing the upper dial. After around 10

seconds of inactivity the level of temperature will be automatically saved.