WWW.CN‐KOVO.COM

3

1. Safetyprecautions

1‐1General

Fuelprecautions

●Pleaseusethenon‐leadgasolineasfuel,andkeepfarawayfromfirewhenrefueling.

●Yourmuststoptheenginebeforerefueling.Wipeoffthespilledgasoline.Donotleavefueland

otherinflammablesneartheexhaustpipe.

Emissionprecautions:

●Donotoperatethewelderinsidearoom,caveandotherinsufficientventilatedareabecauseof

poisonousemissiontopeopleandanimals.

Operatingprecautions

●Dostoptheenginefordailycheck,regularinspection,oilrefillingandcleaningwithreferenceto

“OperationManual”

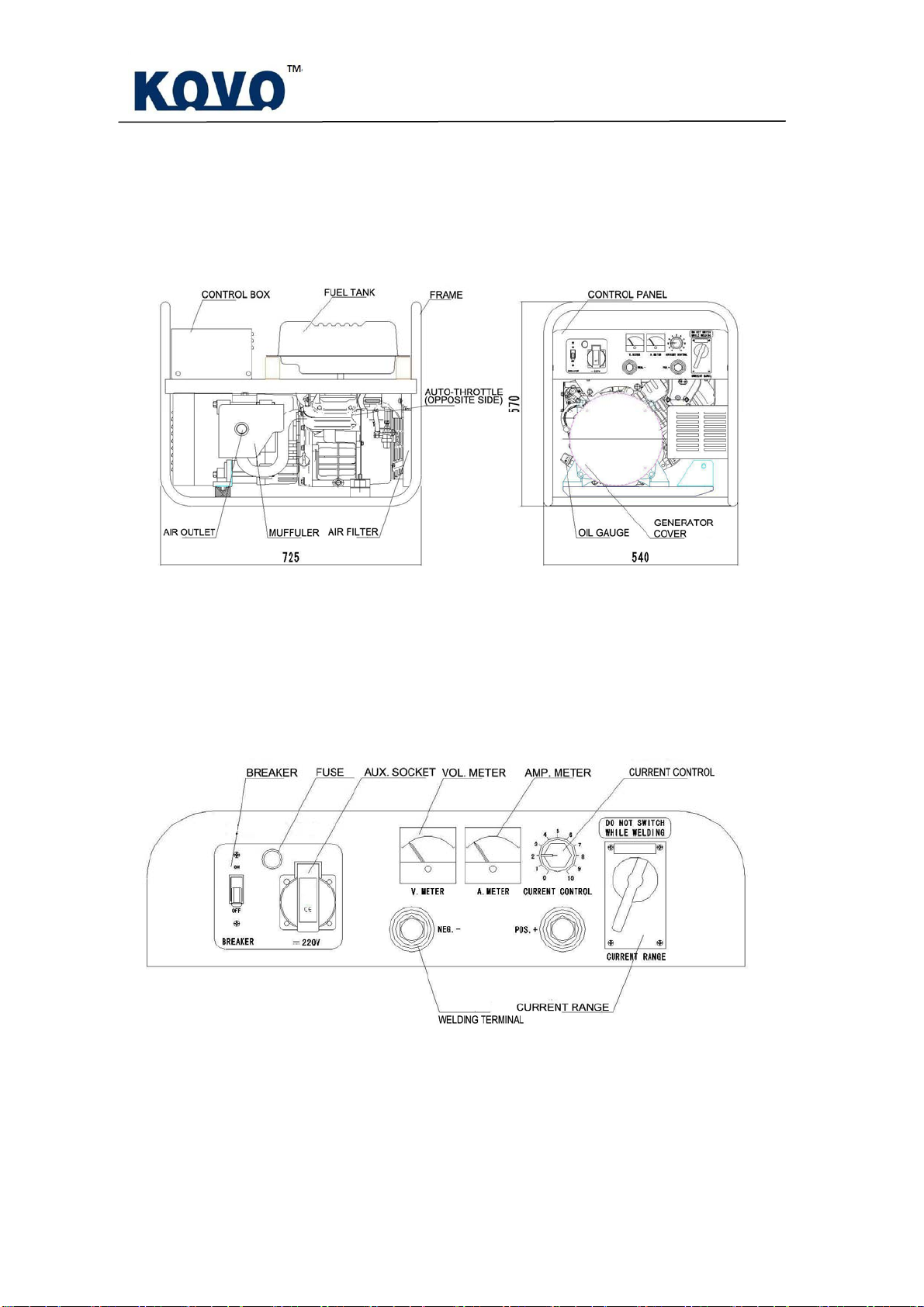

Electricshock

●Pleasedonotoperatewithwethand(s)andinrainyandsnowyday.

●Pleaseconnecttheweldingterminalsafterstopping.Donottouchtheweldingterminalsduring

operating.

●Donotusecablewithinjuredinsulatingcover.

Cleaning

●Usedryclothorpressurizedairforcleaning.Donotusewaterordetergentincaseinsulation

trouble.

Alsopleasebewareofothersafeprecautionsnotcoveredbythismanual.

1‐2Transportation

●Pleasetiethepipeframeofmachinetothecarrierofvehiclewhentransportation.Alsoput

wheel‐stopper.

●Whenloadingorunloading,pleasehangtheframebyropeandpulleyhorizontally.Donotlift

theengineorgeneratorportion.

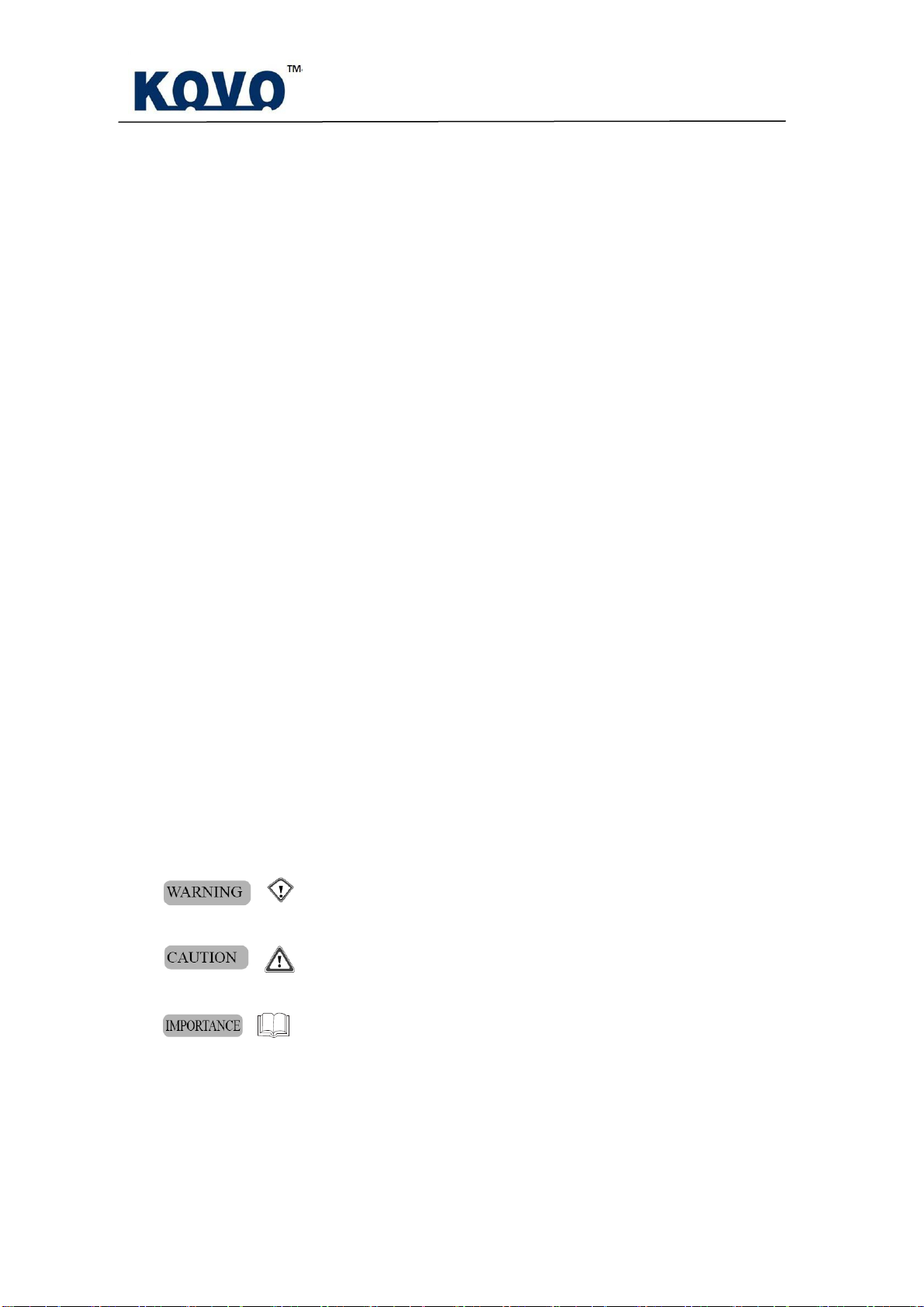

1‐3Installation

●Placethemachineinthelevelground.Thegradientdoesnotexceed5o

●Pleaseremoveobstaclesblockingairinletandoutletofmachineawayformwall.

●Whenyouoperatethemachineonsandysoil,putawoodenboardonthegroundtoavoidsand

comingintothemachine.Thesandmaycauseinsulationtroubles.