2Krampitz Tanksystem GmbH - Operation and Installation Instructions TTD for Tank System - Issue 04/2011

TABLE OF CONTENTS ................................................................................................................................................................................................. 2

SETTINGS OF THE LIMIT SENSOR FOR DAY TANK TTD ................................................................................................................................................ 3

SETTINGS OF THE OVERFLOW GUARD OF DAY TANK TTD .......................................................................................................................................... 3

INSTALLATION AND TEST CERTIFICATE ...................................................................................................................................................................... 4

PRELIMINARY NOTE ................................................................................................................................................................................................................... 5

ABBREVIATIONS USED ............................................................................................................................................................................................................... 5

1. SAFETY INSTRUCTIONS AND REGULATIONS ........................................................................................................................................................................ 5

1.1 Safety instructions .............................................................................................................................................................................................................. 5

1.2 Operation procedures ......................................................................................................................................................................................................... 6

1.2.1 General operation procedures ..................................................................................................................................................................................... 6

1.2.2 Action to take .............................................................................................................................................................................................................. 6

1.2.3 Instruction of operators ............................................................................................................................................................................................... 6

1.2.4 Repairs and maintenance ............................................................................................................................................................................................ 6

1.2.5 Safety tests and inspections ......................................................................................................................................................................................... 6

1.2.6 Handling fuel oil, Diesel fuel and mineral oil ............................................................................................................................................................... 6

2. DESCRIPTION .......................................................................................................................................................................................................................... 7

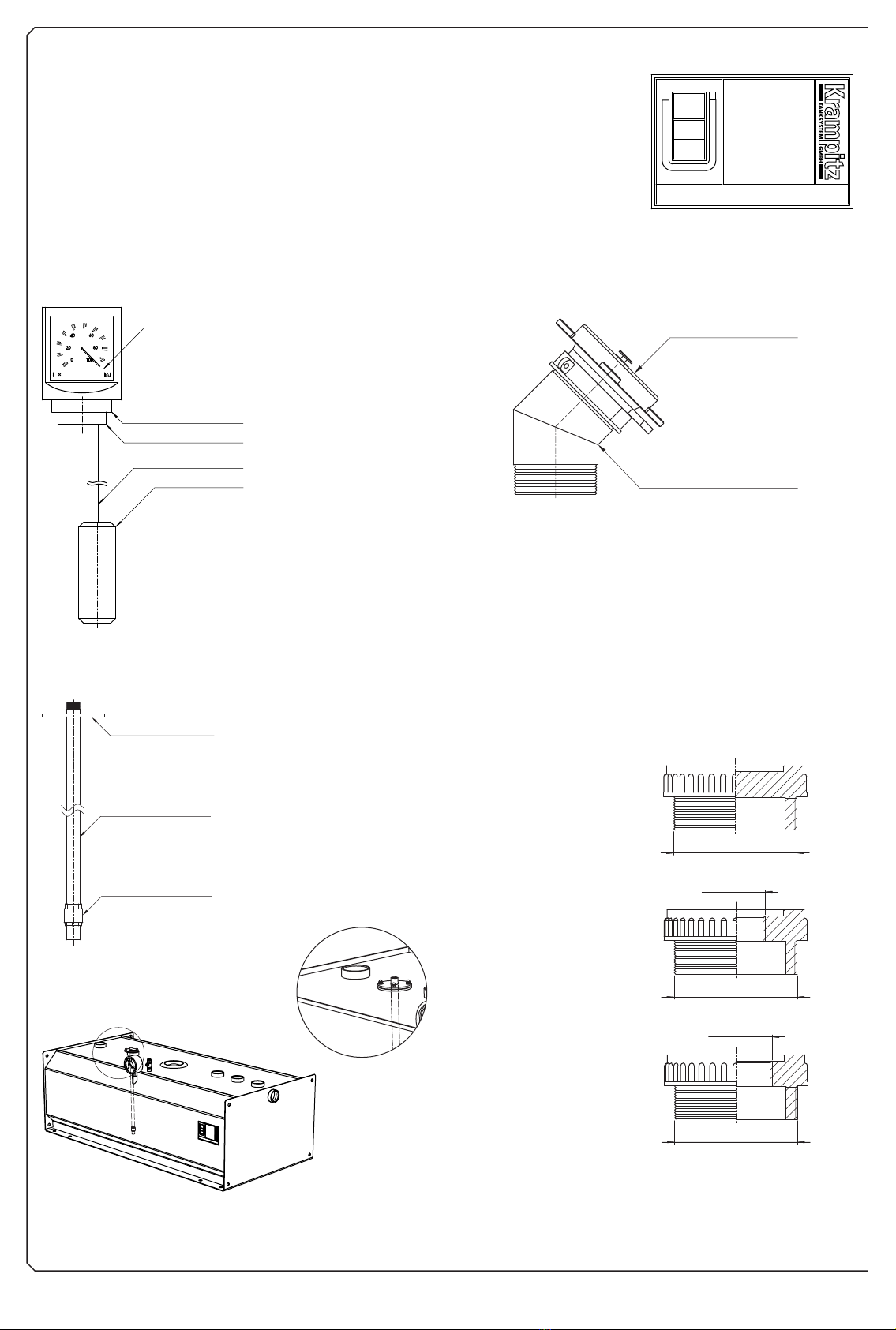

2.1 Illustration of the TTD ......................................................................................................................................................................................................... 7

2.2 Intended use of the TTD ...................................................................................................................................................................................................... 7

2.3 Specifications of the TTD ..................................................................................................................................................................................................... 7

2.3.1 Dimensions and weights of the TTD ............................................................................................................................................................................. 7

2.3.2 Connections of the TTD ................................................................................................................................................................................................ 8

2.3.3 Filling and discharge rates of the TTD from tank trucks ............................................................................................................................................... 8

2.3.4 Plant layout scheme .................................................................................................................................................................................................... 8

2.4. Units of the TTD - standard equipment .............................................................................................................................................................................. 9

2.4.1 The tank vessel ............................................................................................................................................................................................................ 9

2.4.2 The static vacuum leakage indicator ............................................................................................................................................................................ 9

2.4.3 The rupture disk ......................................................................................................................................................................................................... 9

2.4.4 The transport plug ........................................................................................................................................................................................................ 9

2.4.5 The ball valve ............................................................................................................................................................................................................... 9

2.4.6 Corrosion protection for indoor installation ................................................................................................................................................................. 9

2.4.7 The nameplate ............................................................................................................................................................................................................. 10

2.5. Connection kit .................................................................................................................................................................................................................... 10

2.5.1 The level indicator ........................................................................................................................................................................................................ 10

2.5.2 The filling socket .......................................................................................................................................................................................................... 10

2.5.3 The suction pipe - machine flow pipe .......................................................................................................................................................................... 10

2.5.4 The adapter set ............................................................................................................................................................................................................ 10

2.5.5 The machine return pipe .............................................................................................................................................................................................. 11

2.5.6 The bleeding adapter with hood .................................................................................................................................................................................. 11

2.6. Units of the TTD - special design ........................................................................................................................................................................................ 11

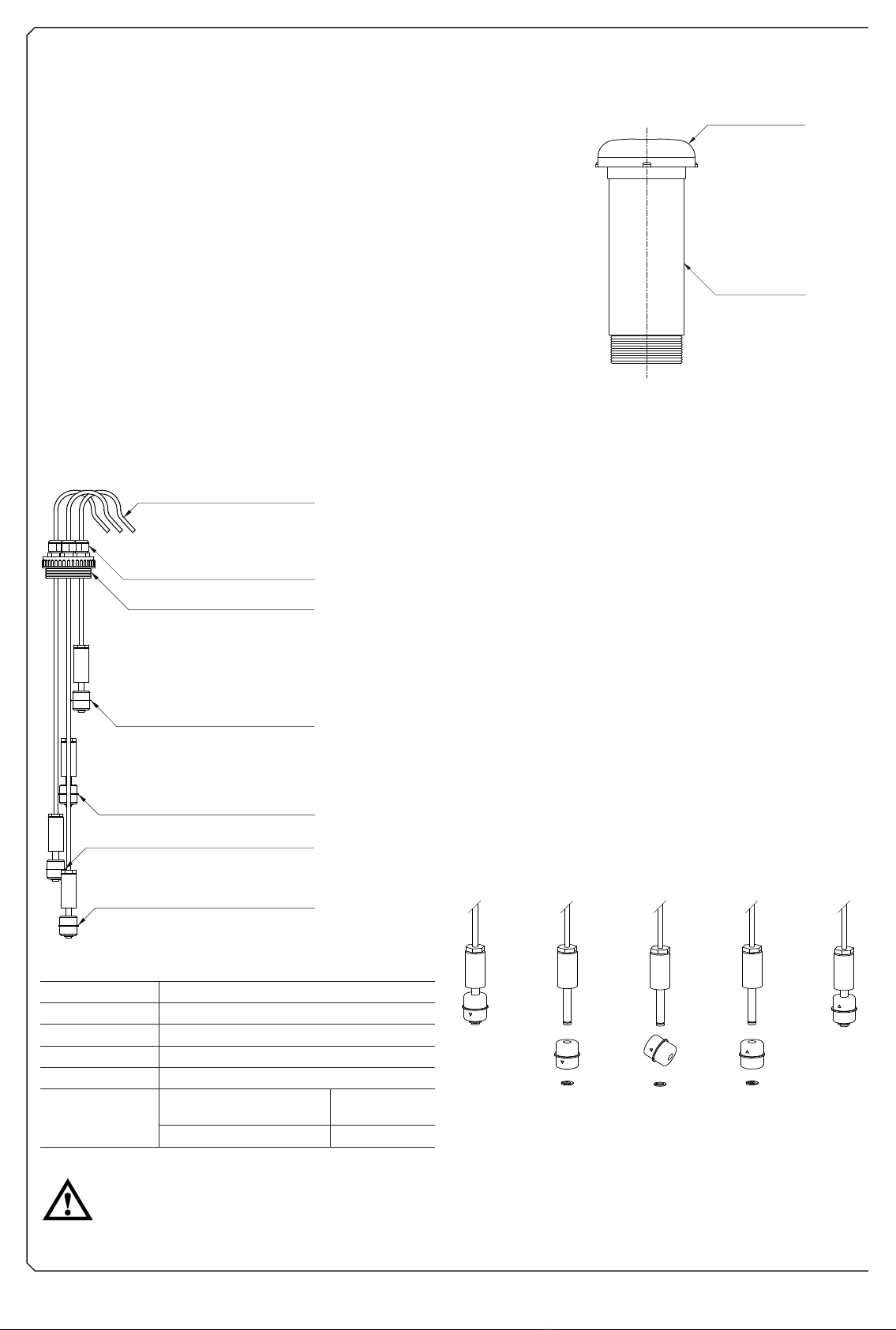

2.6.1 The level sensor ........................................................................................................................................................................................................... 11

2.6.1.1 The level switch (miniature alarm) ..................................................................................................................................................................... 11

2.6.1.2 The electronic volume indicator ......................................................................................................................................................................... 12

2.6.1.3 Floating switch volume indicator and dipstick with dipstick pipe plug .............................................................................................................. 12

2.6.2 Bearing charts ............................................................................................................................................................................................................ 12

2.6.2.1 Bearing charts for TTD 250,TTD 500 ................................................................................................................................................................ 12

2.6.2.2 Bearing charts for TTD 750,TTD 990, TTD 1500 and TTD 1950 ......................................................................................................................... 13

2.6.3 The electronic leakage indicator .................................................................................................................................................................................. 14

2.6.4 The electronic vacuum leakage indicator ..................................................................................................................................................................... 14

2.6.5 The oil warning sensor with alarm and evaluation unit .............................................................................................................................................. 15

2.6.5.1 Function of the oil alarm .................................................................................................................................................................................... 15

2.6.5.2 Configuration of the oil alarm ........................................................................................................................................................................... 15

2.6.6 The overfill guards ....................................................................................................................................................................................................... 15

2.6.6.1 The limit sensor with PTC thermistor - only for fuel oil and Diesel fuel .............................................................................................................. 15

2.6.6.2 The overfill guard with evaluation logic ............................................................................................................................................................. 15

2.6.6.3 Overview: Possible switching points and control instructions ............................................................................................................................ 16

2.6.7 The pump combination ................................................................................................................................................................................................ 16

2.6.7.1 Other pumps from the delivery range of Krampitz Tanksystem GmbH ............................................................................................................... 16

2.6.8 The tank heater............................................................................................................................................................................................................. 16

2.6.9 The wall brackets ......................................................................................................................................................................................................... 16

2.6.10 The supporting column .............................................................................................................................................................................................. 17

2.6.11 The Krampitz special nut with captive washer ........................................................................................................................................................... 17

2.6.12 The feet ...................................................................................................................................................................................................................... 17

3. START-UP ................................................................................................................................................................................................................................. 17

3.1 Transport of the TTD ............................................................................................................................................................................................................ 17

3.2 Wall mounting of the TTD ................................................................................................................................................................................................... 17

3.3 Setting up the TTD on feet / supporting column .................................................................................................................................................................. 18

3.4 First start-up ....................................................................................................................................................................................................................... 18

3.5 Operation sequence ............................................................................................................................................................................................................ 18

4. DOCUMENTATION .................................................................................................................................................................................................................. 19

5. WARRANTY ............................................................................................................................................................................................................................. 19

TABLE OF CONTENTS