1

OWNER’S MANUAL FOR #309 BLOWER

READ ALL INSTRUCTIONS BEFORE USING BLOWER

IMPORTANT: Unpack blower immediately and check for damage to shipping. Place any damage claim

with delivering carrier, saving all packing materials for inspection. Our warranty covers manufacturer’s

defects only. DO NOT return to shipper.

File instructions for future reference and ordering replacement parts.

A WORD ABOUT YOUR BLOWER. This blower is designed to blow CELLULOSE insulation fibers,

properly conditioned by agitation in the hopper. This unit is not designed to blow fiberglass, mineral wool,

or similar abrasive material, which would cause damage to fan and chamber. Consult the manufacturer for

a wide range of machines designed to handle all fibers.

Declaration of Incorporation -The 309 blower’s intended use is with cellulose machines and is an integral

part of the machine’s operation. The blower is not intended to be used as a separate piece of equipment as

this would create an unsatisfactory condition. The assembler performing final assembly of blower unit

must ensure proper installation to make certain that final health and safety requirements have been met.

Your blower is designed with an abrasive resistant fan and chamber, powered by a high speed, universal,

brush-type motor.

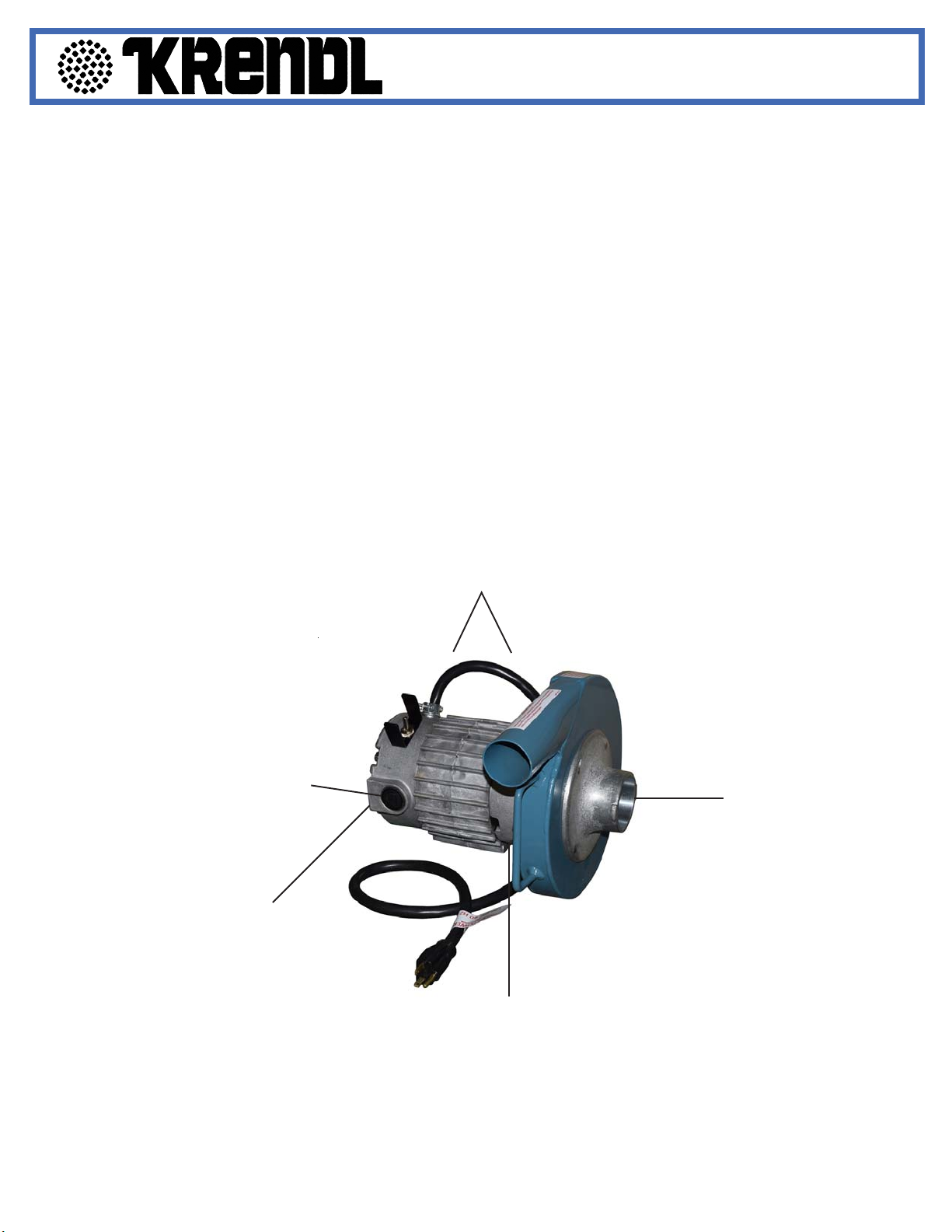

#309

16.8 amp Motor, 120V

(8.4 amp, 230V)

1.5 h.p. Motor

No load RPM 16,500

2016 Watts

CHAMBER FAN DIAMETER PRODUCTION AMPS

SMALL 9” 6 ½” 800 lbs/hr 12 | Chamber Outlet: 2” or 2 ½”

MEDIUM 10” 7 ½” 1000 lbs/hr 15 | Blower Intake: 2-3/8”

| Fan bore: 9/16”

LIMITED WARRANTY

This model carries a one (1) year warranty against defects in material and workmanship from date of

invoice to the original purchaser. If blower needs service during that time, call your supplier immediately.

Do not attempt to service blower as this would void warranty.

This warranty does not cover ordinary wear, which occurs during normal use of the machine. Materials

such as fiberglass and mineral wool, etc. because of their abrasiveness, are not recommended for use with

this blower.

This warranty does not cover damage to unit caused by heat (i.e armature, field coil). In most cases, heat

damage is a result of improper use. See operating instructions.

The warranty also excludes switches and cords – the use or abuse of which cannot be controlled.

The warranty also excludes damage or breakage due to carelessness, accidents, or improper use.

We do not assume responsibility for repairs made or attempted by unauthorized persons. Returns, in-

warranty, must be sent to our factory for examination and determination of the defect.

All blowers or parts must be returned prepaid with necessary information as to date of

purchase, model, and serial number with description of the problem and defect.