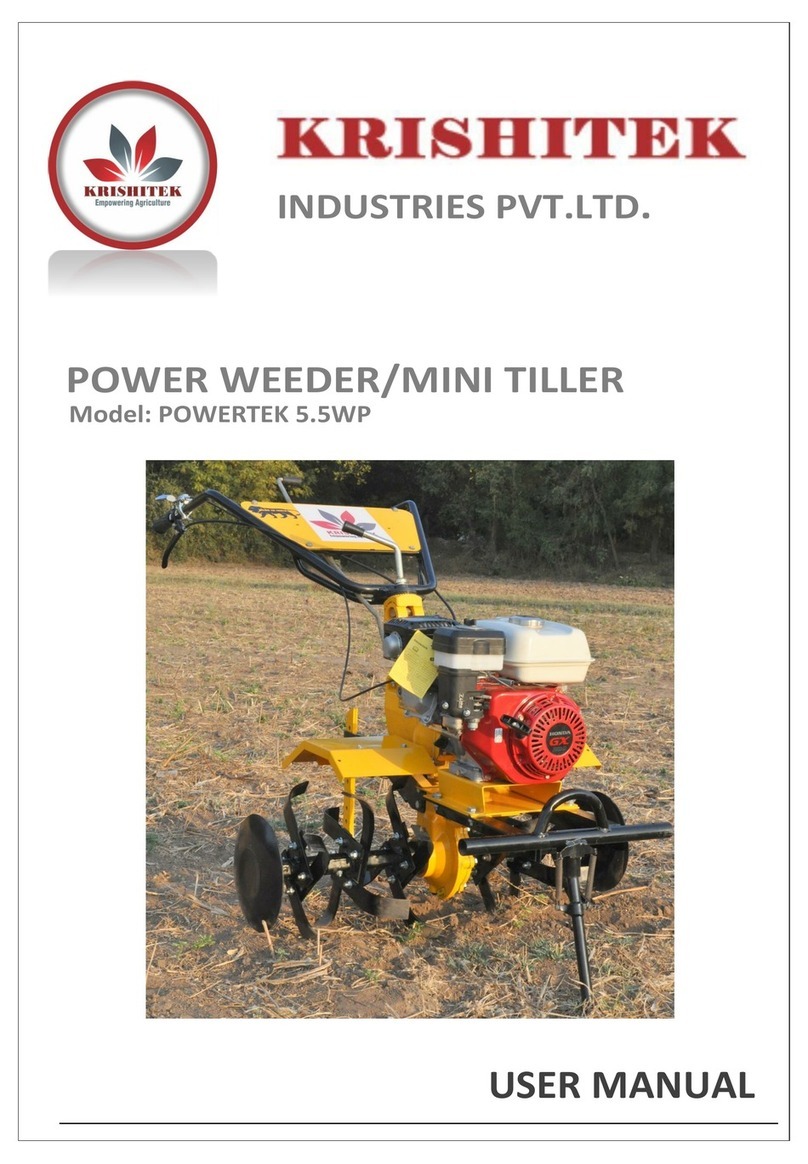

KRISHITEK POWERTEK 5.5WP User manual

Other KRISHITEK Tiller manuals

Popular Tiller manuals by other brands

MTD

MTD OHV Series Original operating instructions

YAT

YAT YT5601-01 Assembly, Use, Maintenance Manual

Craftsman

Craftsman 917.296010 owner's manual

Troy-Bilt

Troy-Bilt OEM-290-260 Operator's manual

Scheppach

Scheppach MTP560 Translation from the original instruction manual

GARDEN WAY

GARDEN WAY 12194 owner's manual

Classen

Classen STAND-AER SA-25 Operator's manual and parts list

Craftsman

Craftsman 850 Series owner's manual

DR

DR PILOT 2 Safety & Operating Instructions

Altrad

Altrad ATIKA BH 1400 N Original instructions, safety instructions, spare parts

WIL-RICH

WIL-RICH 2500 Operator's manual

Viking

Viking HB 685 instruction manual