BIC · Edition 09.22

EN-7

odourless and poisonous! Conduct a flue gas

analysis.

– The burner must only be commissioned by

authorized trained personnel.

➔If the burner does not ignite even though the auto-

matic burner control unit has been switched on and

off several times: check the entire system.

➔After ignition, monitor the flame and the gas and

air pressure measured on the burner. Measure the

ionization current. Switch-off threshold– see au-

tomatic burner control unit operating instructions.

+μA –

Z

➔

The burner must only be ignited at low-fire rate

(between 10 and 40% of the rated capacityQmax)–

see type label.

5.2 Determining the gas and combustion air

flow rates

➔Qgas: Gas flow rate in m3/h (ft3/h)

➔PB: Burner capacity in kW (BTU/h)

➔Hi: Gas heating value in kWh/m3(BTU/ft3)

➔Qair: Air flow rate in m3(n)/h (SCFH)

➔ λ: Lambda, air index

➔

Lmin: Minimum air requirement in m3(n)/m3(n) (SCF/

SCF)

➔

Information on the gas quality supplied can be

obtained from the gas supply company.

Common gas qualities

Gas type Heating value

HuHoLmin

kWh/

m3(n)

BTU/

SCF

m3(n)/

m3(n)

(SCF/

SCF)

Natural gas H 11.0 1114 10.6

Natural gas L 8.9 901 8.6

Propane 25.9 2568 24.4

Low calorific

value gas 1.7–3 161–

290 1.3–2.5

Butane 34.4 3406 32.3

➔

Data in kWh/m

3

(n) refer to the lower heating val

-

ueH

u

and data in BTU/SCF refer to the higher

heating valueHo(gross calorific value).

➔

A minimum air excess of 20% (lambda=1.2) should

be set in a cold furnace for initial adjustment since

the air volume falls as the temperature rises.

➔

Fine adjustment should be carried out at max.

furnace temperature and at as high a capacity

demand as possible.

5.3 Notes on the flow rate curve

➔

If the gas density in the operating state differs from

that reflected in the flow rate curve, convert the

pressures according to the local operating state.

pB = pM .

B

➔

δM: Gas density reflected in the flow rate curve

in kg/m3(lb/ft3)

➔ δB: Gas density in operating state in kg/m3(lb/ft3)

➔pM: Gas pressure reflected in the flow rate curve

➔pB: Gas pressure in operating state

5.4 Burners without gas measuring orifice

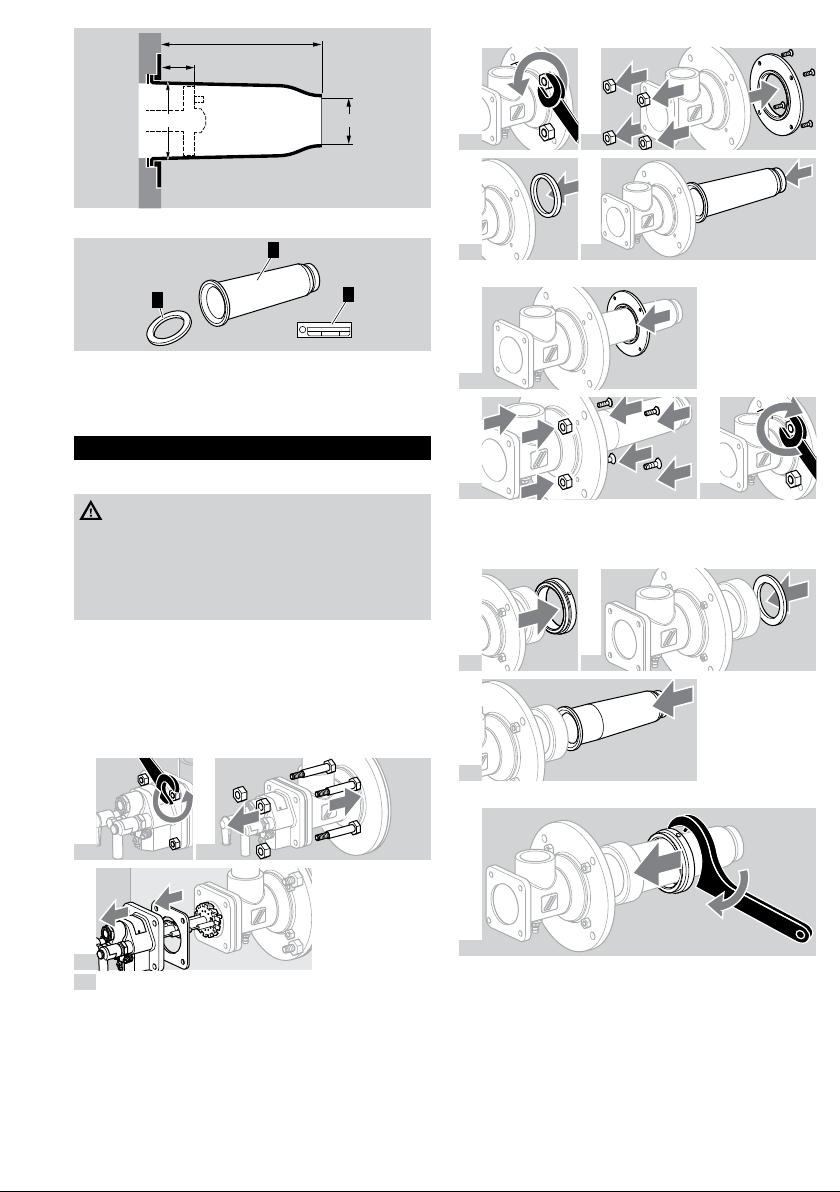

1 Read the gas pressure pgas and air pressure pair

from the enclosed flow rate curve for cold air on

the basis of the calculated flow ratesQ.

[mbar (inch WC)]

[m3/h (ft3/h)]

pgas pair

pair

pgas

Qair

Qgas

➔

Note possible capacity changes due to positive

or negative pressures in the furnace/combustion

chamber. Add positive pressures or subtract neg-

ative pressures.

➔As not all the effects caused by the equipment are

known, setting the burner using the pressure values

is only approximate. It is possible to set the burner

precisely by measuring the flow rates or flue gas.

5.5 Burners with gas measuring orifice

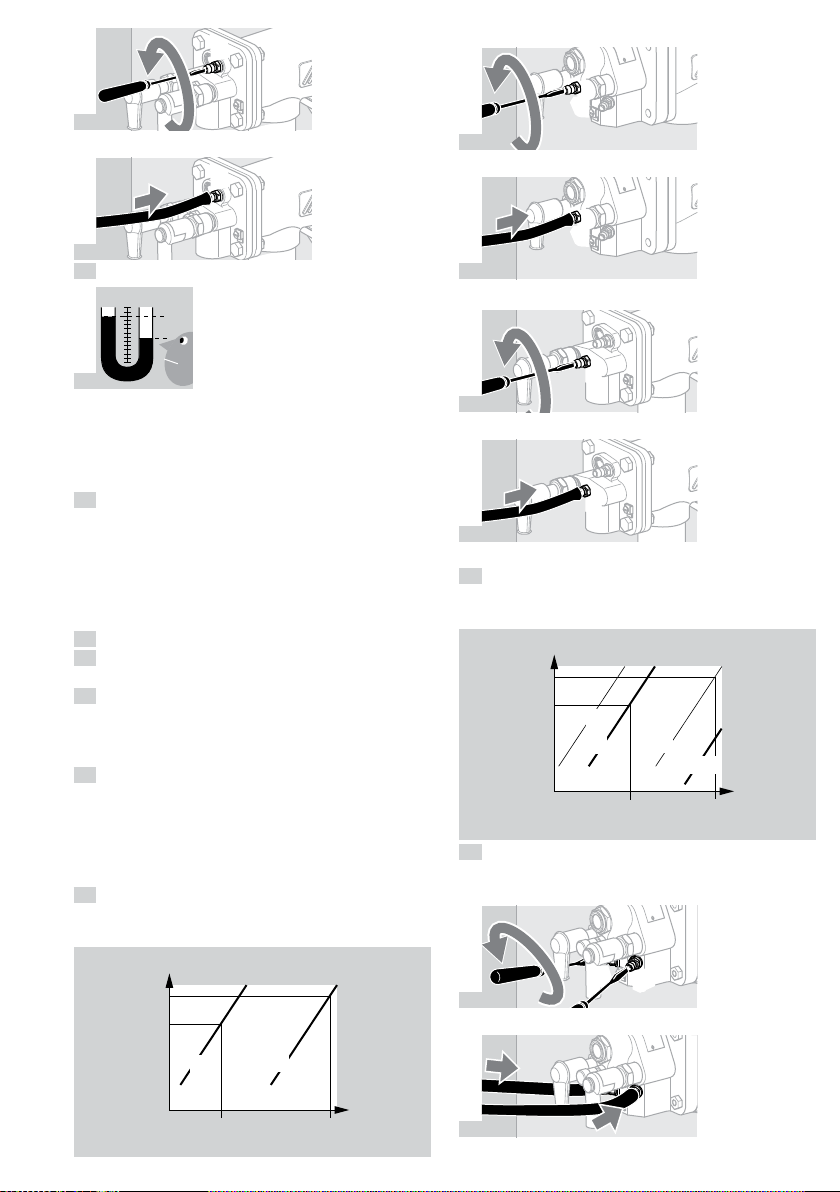

1 Read the differential pressureΔpgas and air pres-

surep

air

from the flow rate curve for cold air on the

basis of the calculated flow rates.

[mbar (inch WC)]

[m3/h (ft3/h)]

Δpgas pair

pair

pgas

Qair

Qgas

pgas

∆pair

➔Note possible capacity changes (air) due to pres-

sure loss in the furnace/combustion chamber. Add

positive pressures or subtract negative pressures.

➔

The differential gas pressure Δp

gas

measured on

the integrated gas measuring orifice is independent

of the furnace chamber pressure.