3

1. Safety instructions

The warnings in the manual are marked with a triangular warning sign.

Failure to comply with these warnings may result in serious consequences or even death.

Warnings

This water heater is not suitable for water heating in swimming pools.

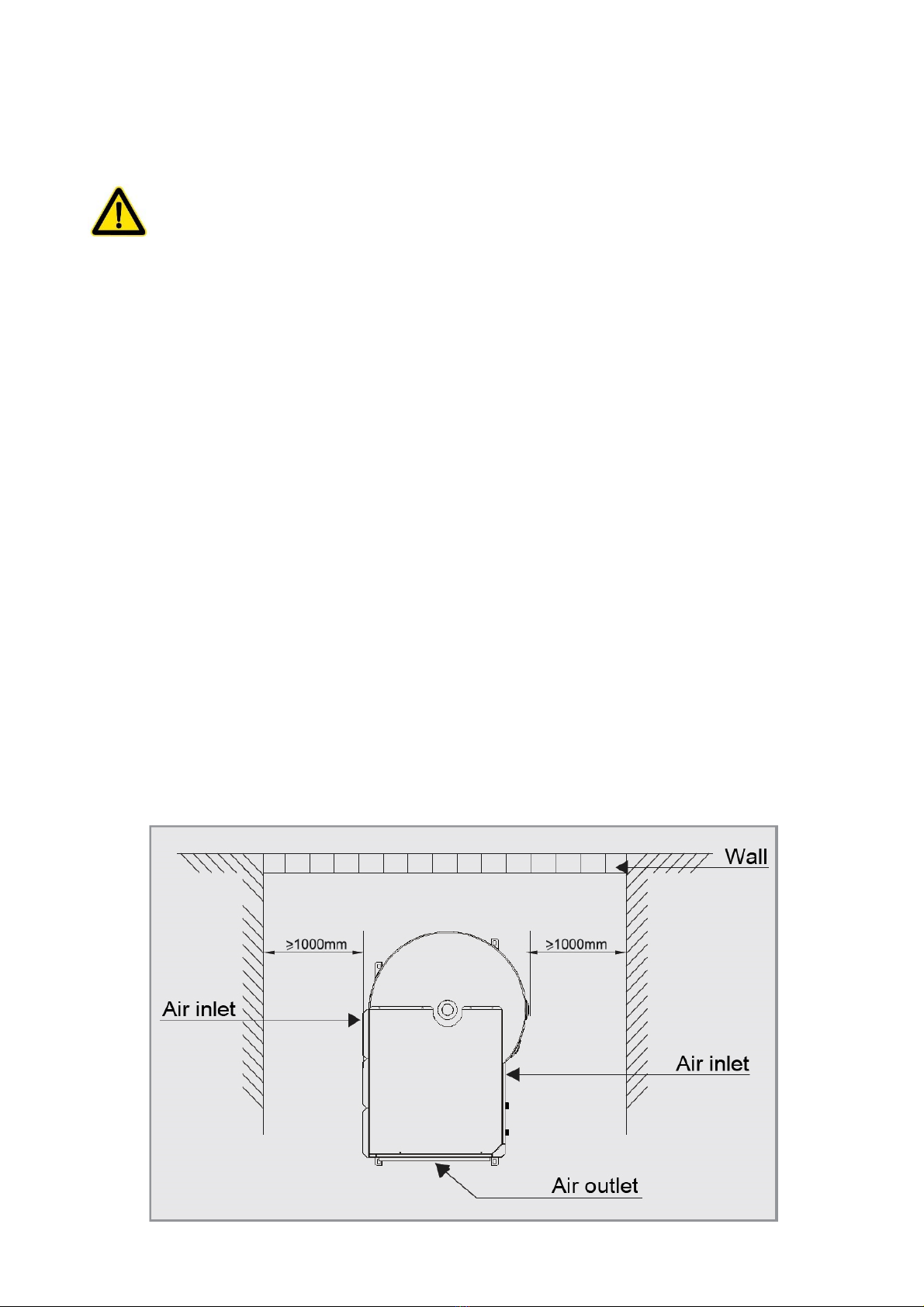

The water heater should be placed where it won’t damage the adjacent area or underlying

structure of the heat pump water heater even if there is leak at the water heater or the joint. When

these installation locations cannot be avoided, it is recommended to install a suitable water drain

pan in the lower part of the water heater for adequate drainage of water.

If the water heater is installed in a closed water supply system, measures should be taken to

prevent hot water from flowing back; for example, a check valve is installed on the cold water

supply pipeline to prevent hot water from flowing back due to thermal expansion.

Before manually operating the temperature and pressure safety valve (hereinafter referred to as

P/T valve), preventive measures must be taken to avoid the risk of scalds by the hot water flowing

out from the P/T valve.

The thermal expansion of the closed water supply system may cause the P/T valve to periodically

relieve pressure. Contact the water heater supplier for how to correct this situation. DO NOT

BLOCK THE P/T VALVE.

The P/T valve should be inspected every 6 months for its performance or replaced at an interval

of not more than 2 years. The P/T valve should be replaced more frequently in the high-occurrence

areas of water subsidence.

When using and reusing the refrigerant, please comply with relevant environmental regulations.

The refrigerant is not allowed to be discharged into the environment. R134a refrigerant is used

for this equipment, which is non-flammable and does not have a devastating effect on the ozone

layer.

When processing or operating components related to the refrigerant circuit, the refrigerant should

be discharged to ensure safe operation.

The high pressure insulation test of the water heater can only be carried out between the live wire

and the ground wire as well as the null line and the ground wire. The test between the live wire

and the null line will damage the electronic equipment.

All electrical installation and wiring must be performed by qualified professionals and subject to

wiring rules and the requirements of the local authority.