2

1

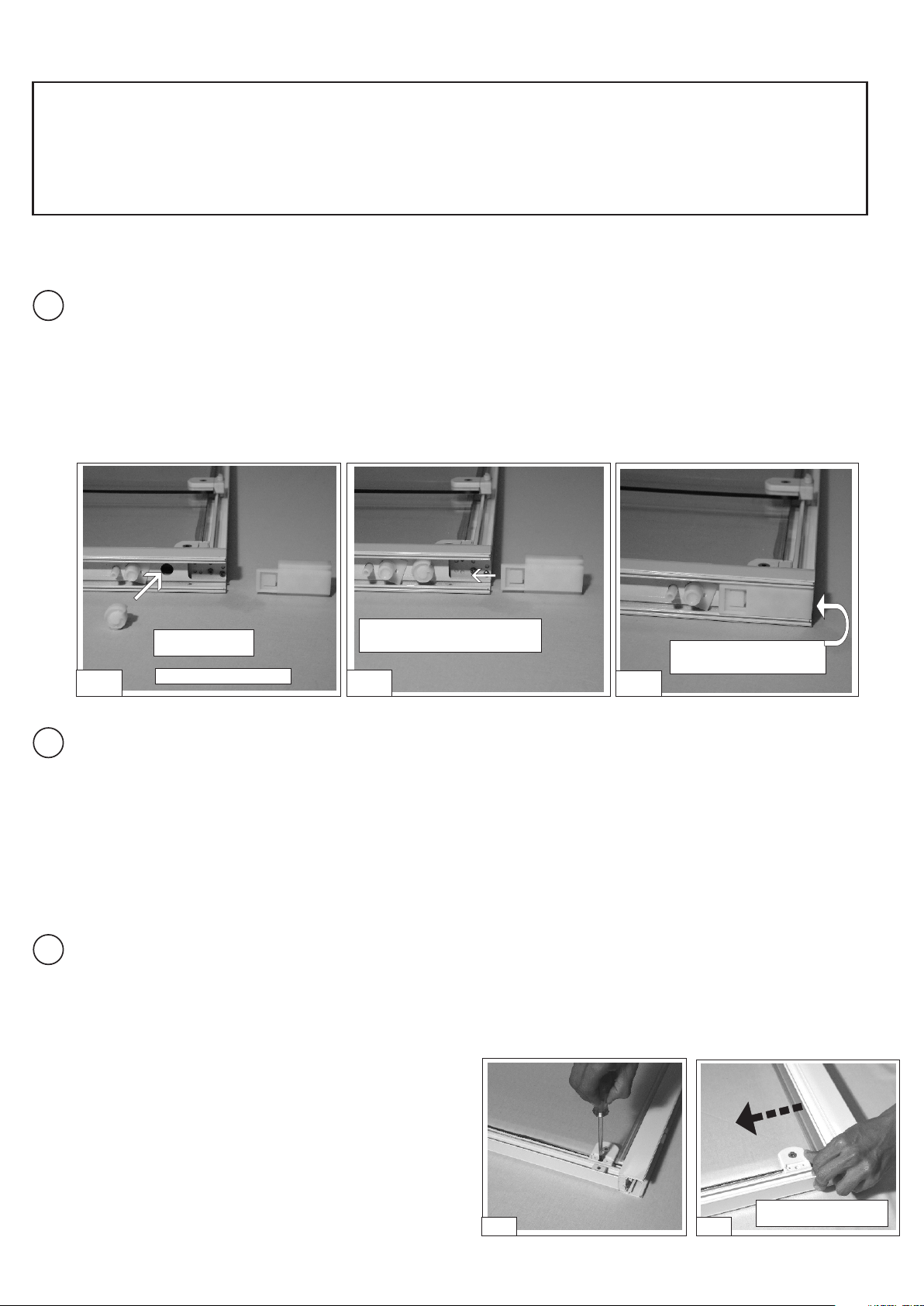

14 15 16

17 18 19

20 21

Seal shown shorter

for clarity

Insert glazing seals as

shown, around the

outside of the fixed panel.

Also at this stage fit the inner fixed

patch covers as shown, you will not

be able to fit all of these once the

door glass is installed.

Remove the wheel patch

fixings from the door glass

using the 4mm allen key

supplied. Sit these patch fittings into

TOP rail upside down then turn the

right way around to lock them into the

rail.

Carefully feed the glass into

the unit and match up the top

holes with the wheel patches.

Screw the inner cover back on.

Ensure the shoulders of the patch

fittings are tight against the top edge

of the glass.

If the handing of the door glass is

being changed then you will need to

remove the quick release patches

and splash seal and ensure they are

to the bottom of the door with the

levers pointing towards each other.

FIT COVER CAPS, to all

patch fittings and each wallpost

Secure wallpost cover caps

using No.4 x 10mm long screws

provided.

FIT VERTICAL DOOR seal

onto the opposite edge of the

sliding door to the handle.

Position stop blocks to prevent the

handle of sliding door impacting on

edge of fixed panel, then tighten allen

key grub screws with 2.5mm Allen

Key.

TIP

If seals feel tight, then

wetting in clean water

will help. Ensure you do

not stretch the seals. Trim

to correct length.

Adjust the hanging of the door

so that the closing edge of the

glass meets the closing seal

evenly over it’s entire height. Gain

access to screw “A” by removing the

top patch cover.

SLIDING DOOR

VIEW

FROM INSIDE

TOP

TO RAISE THIS

SIDE OF DOOR

USE SCREW

‘A’

TO LOWER

THIS SIDE OF

DOOR USE

SCREW ‘B’

A

B

TO RAISE THIS

SIDE OF DOOR

USE SCREW

‘A’

TO LOWER

THIS SIDE OF

DOOR USE

SCREW ‘B’

A

B

A

B

Roller bearing adjustment- using

screwdriver, loosen screw (do not remove), re-

position in slot and re-tighten.

Patch fitting adjustment- using allen key,

loosen screw (do not remove), lower glass and

re-tighten.

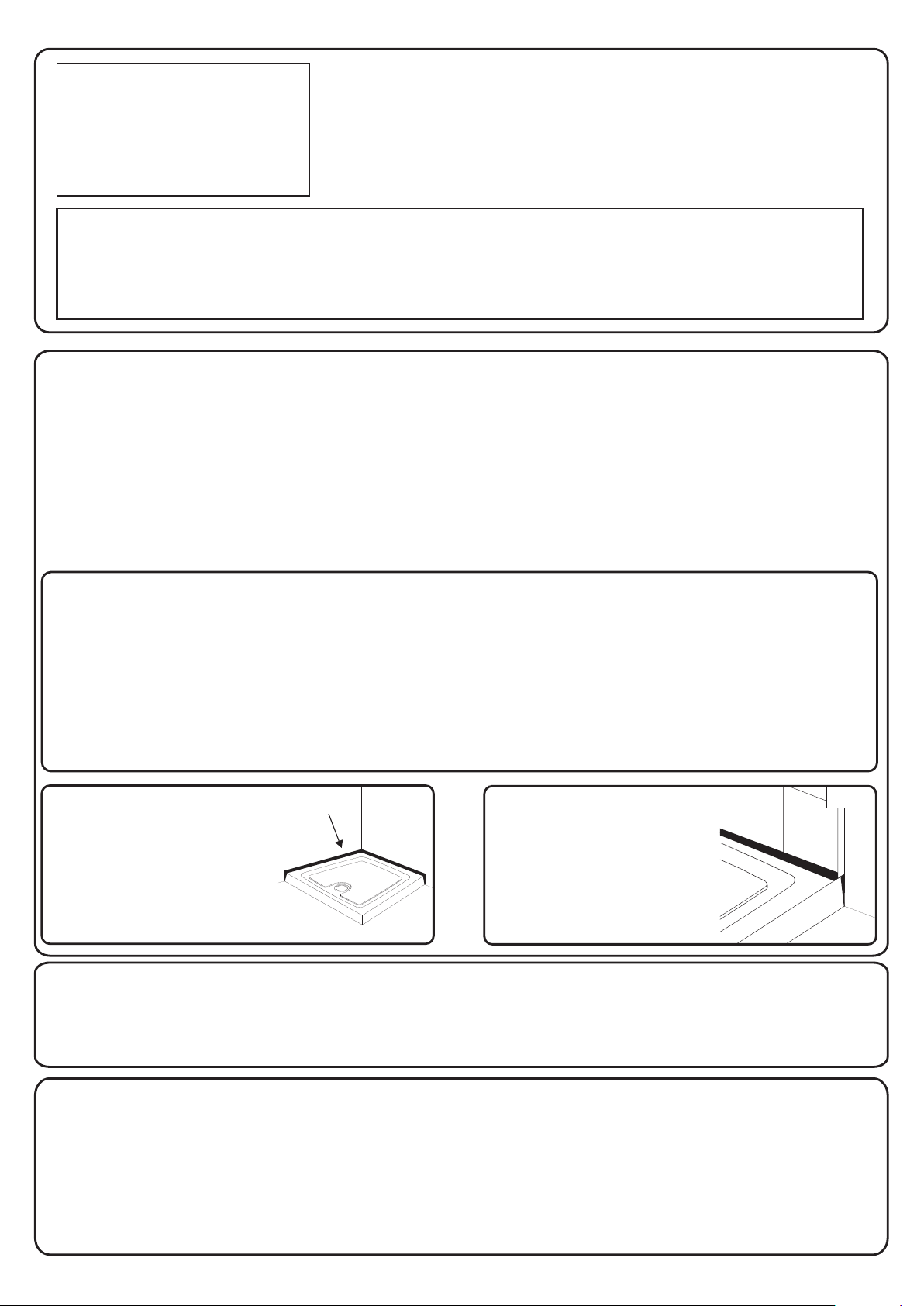

FIXED

DOOR

Silicone seal the wallposts.

Both wallposts should be

sealed vertically to the tiled /

panelled walls on the Outside &

Inside of the enclosure.

Silicone seal the enclosure

to the tray on the outside only

You should also seal the joint

as shown.

IMPORTANT!! Do not seal to the tray

on the inside, this will prevent drainage

of the frame work and will cause

leakage problems

Seal joint at both ends

of the bottom rail

Keep inner fixings

to hand when

positioning the

glass door

?

?

Check the running of the

door, vasaline can be applied to

the bottom track to improve the

sliding action

Check that the shim strip has

been installed under the bottom

rail

?Check that all the screws and

fittings are fully tightened

?Ensure that the quick release

levers are to the bottom of the

door

?Leave for 24hrs before use to

allow silicone sealant to cure

Bottom & Top

TIP

Support weight of

glass on your foot

when securing to the top

wheel patches

PLEASE ENSURE THAT AFTER ADJUSTMENT

ALL SCREWS ARE FULLY TIGHTENED