- 3 -

BASICPRINCIPLES

1. Inadditiontotherecommendationsgiveninthismanual,legislationonworksafetyandaccidentpreventionmust

alsobe respected.

2. Adviceis indicatedonthe machine, specifyingsafetyrecommendations in ordertoprevent accidents.

3. Beforetravellingonpublicroads,theoperatormustensurethatthemachineconformstoroadtrafficregulations.

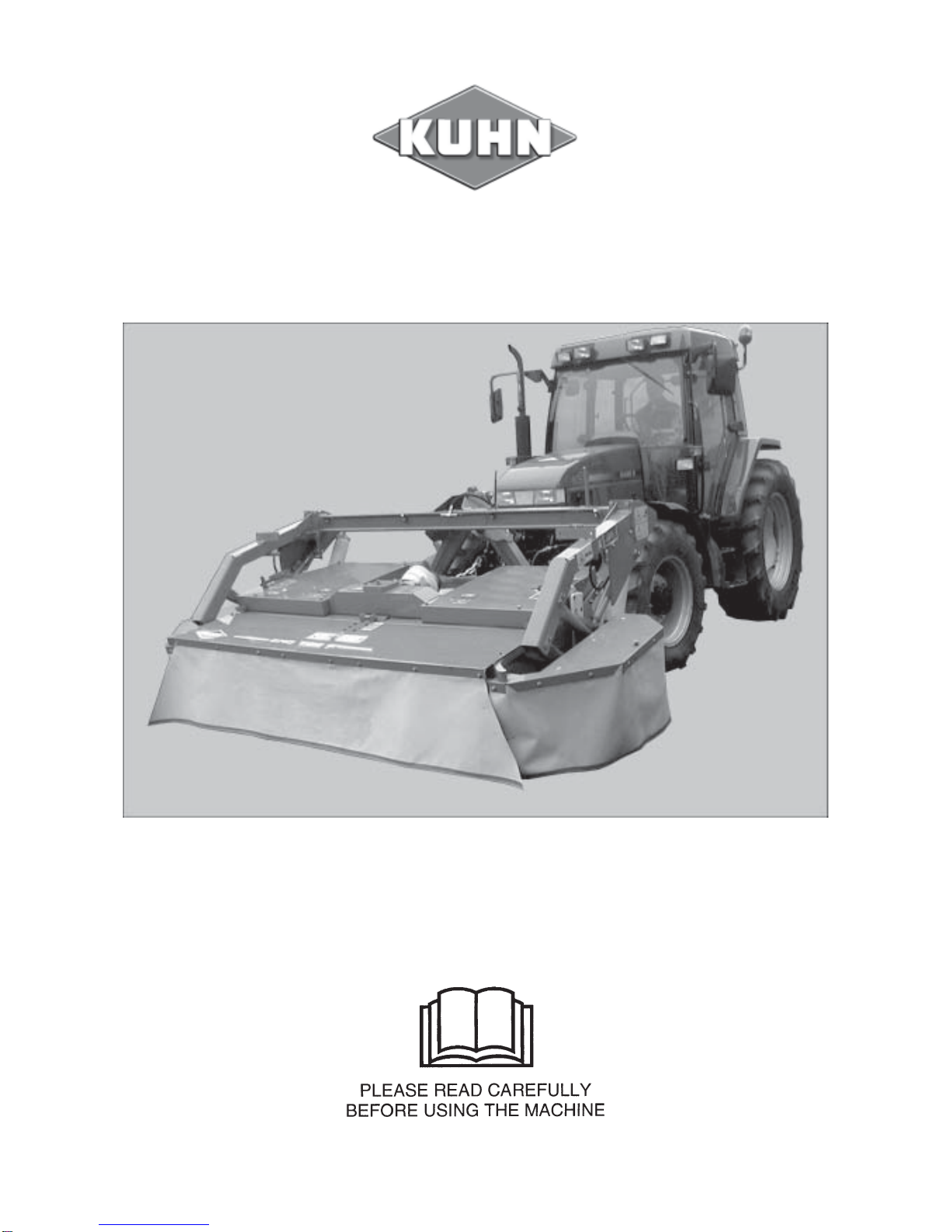

4. Before starting work, the operator must be familiar with all machine controls, handling devices and their

functions. Once at work, it is too late to do so !

5. Donot wear loose clothingwhich could becomecaught up inmoving elements.

6. Useatractorequippedwithasafetycab.Keepwindowsandroofhatchclosedforreducedsoundlevelwhile

operatingthePTOdrivenimplement.

7. Beforestartingupthemachineandbeginningwork,checkthesurroundingarea(bewareofchildren!).Make

surethereissufficientvisibility.Keepallpeopleandanimalsawayfromthedangerzoneofthemachine(risk

ofprojection!)

8. Carryingpeople oranimals on themachine when workingorin transport isstrictly forbidden.

9. Machine must only be attached to tractor using means provided and in accordance with current safety

standards.

10. Whenattaching or removing the machine,placetheparkingstandinto the corresponding position.

11. Specialcare should be takenwhenattaching or removing themachinefromthe tractor.

12. Beforeattaching the machine, make surethatthemaximum permitted front axle weightandgrossweight of

thecombinationare not exceeded.

13. Donot exceed themaximumpermittedlength and widthauthorizedbyroad traffic regulations.

14. Beforetransportingthemachineonpublicroads,ensurethatalllegallyrequiredguardsandindicators(lights,

reflectors...) are in place andin good operation.

15. All operating controls (cords, cables, rods ...) must be positioned so that they cannot be set off accidently,

riskingaccidentor damage.

16. Before travelling on public roads, put the machine into its transport position as instructed in this operator’s

manual.

17. Neverleavethe tractorseatwhilethe machineisoperating.

18. Drive speed must be adapted to ground conditions as well as to roads and paths.

Alwaysavoidabruptchangesofdirection.

19. Precisionsteering,tractoradherence,roadholdingandefficientbrakingareinfluencedbythetypeofimplement,

weight, ballast of front axle, ground or road conditions. It is therefore of utmost importance to be cautious in

everygivensituation.

20. Beparticularlycautiouswhenturningcorners,payingattentiontomachineoverhang,length,heightandweight.