2. - Contents

FC813R

3

KN013CGB K

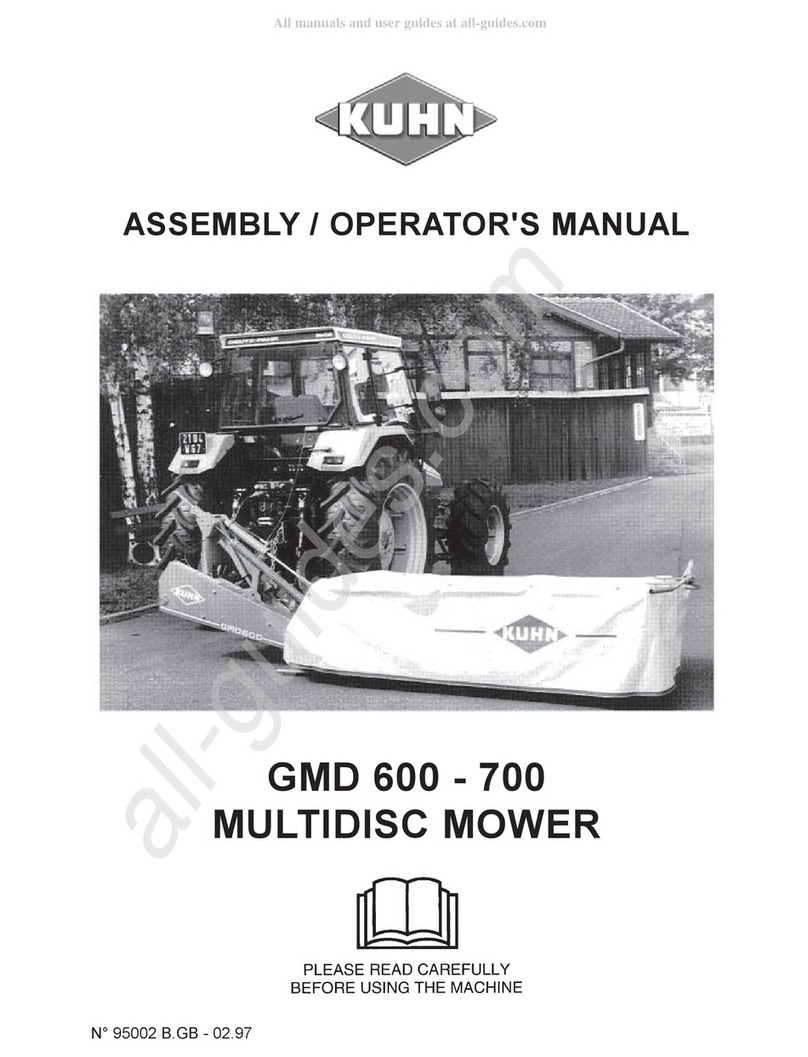

Mower conditioner

5. Machine specifications................................................................................................ 31

5.1 Description and glossary ............................................................................................................... 31

5.2 Technical specifications................................................................................................................. 34

5.3 Sound levels.................................................................................................................................. 34

6. Putting into service...................................................................................................... 35

6.1 Description of control elements ..................................................................................................... 35

6.1.1 Positioning and parking....................................................................................................36

6.1.2 Description of the controls................................................................................................37

6.1.3 Putting the machine from headland turn into transport position and vice versa............... 38

6.1.4 Control box protection...................................................................................................... 40

6.1.5 Description of the connection........................................................................................... 41

6.2 Coupling and uncoupling............................................................................................................... 42

6.2.1 Description of coupling elements ..................................................................................... 42

6.2.2 Preparing the tractor......................................................................................................... 43

6.2.3 Coupling the machine.......................................................................................................44

6.2.4 Hydraulic connections......................................................................................................47

6.2.5 Electrical connections....................................................................................................... 49

6.2.6 Primary PTO shaft............................................................................................................ 50

6.2.7 Intermediate PTO shafts................................................................................................... 52

6.2.8 Adjusting the machine......................................................................................................55

6.2.9 Uncoupling the machine................................................................................................... 56

7. Instructions for transport............................................................................................ 58

7.1 Putting the machine into transport position ................................................................................... 58

7.2 Conformity with the road regulations............................................................................................. 63

8. Instructions for work................................................................................................... 64

8.1 Putting the machine into work position.......................................................................................... 64

8.2 Putting the machine in headland turn position............................................................................... 68

8.3 Adjustments in working position .................................................................................................... 69

8.3.1 Cutting height................................................................................................................... 69

8.3.2 Ground pressure .............................................................................................................. 70

8.3.3 Conditioning intensity....................................................................................................... 74

8.3.4 Swathing system.............................................................................................................. 75

8.4 Machine use .................................................................................................................................. 76

8.4.1 Lateral offset..................................................................................................................... 78

8.4.2 Drive speed...................................................................................................................... 80