5

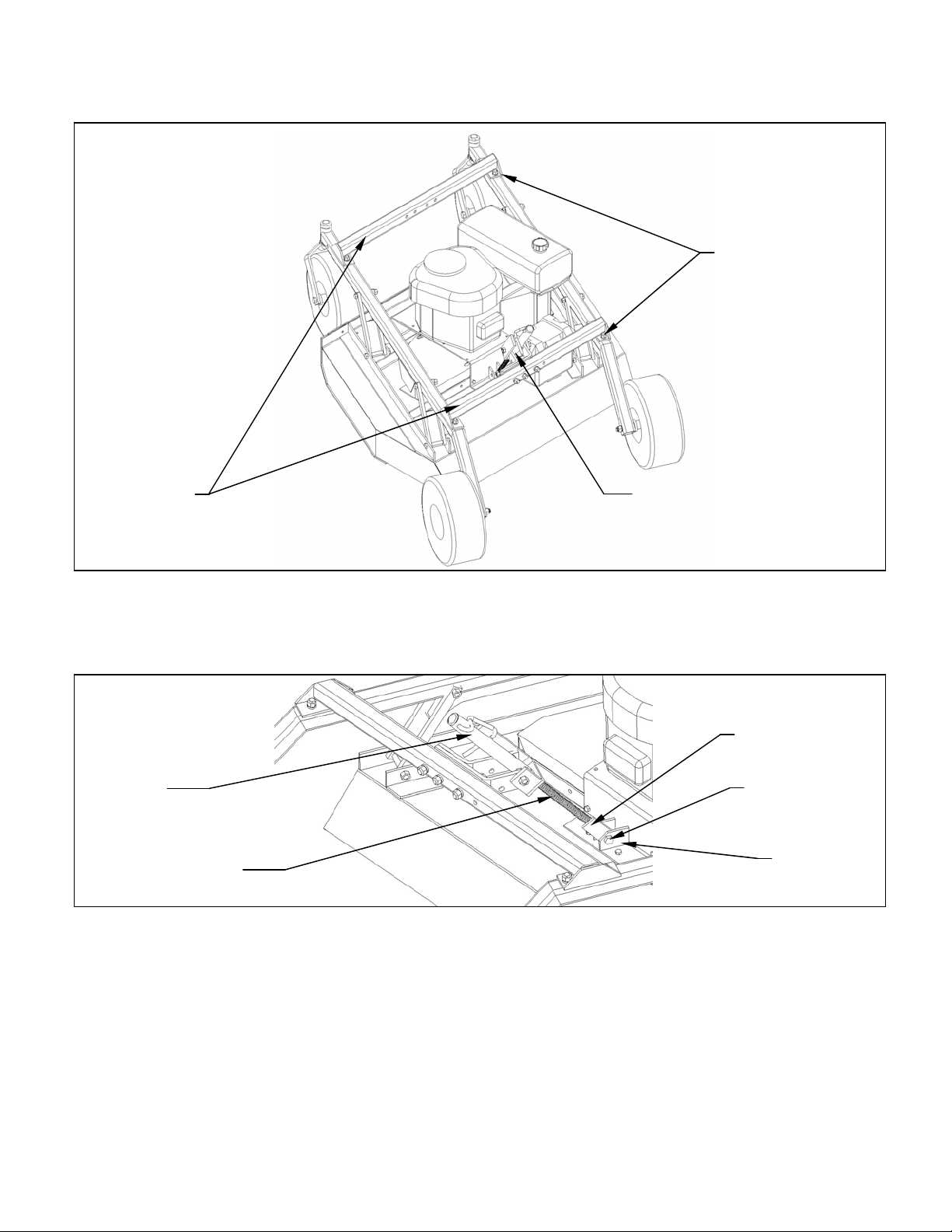

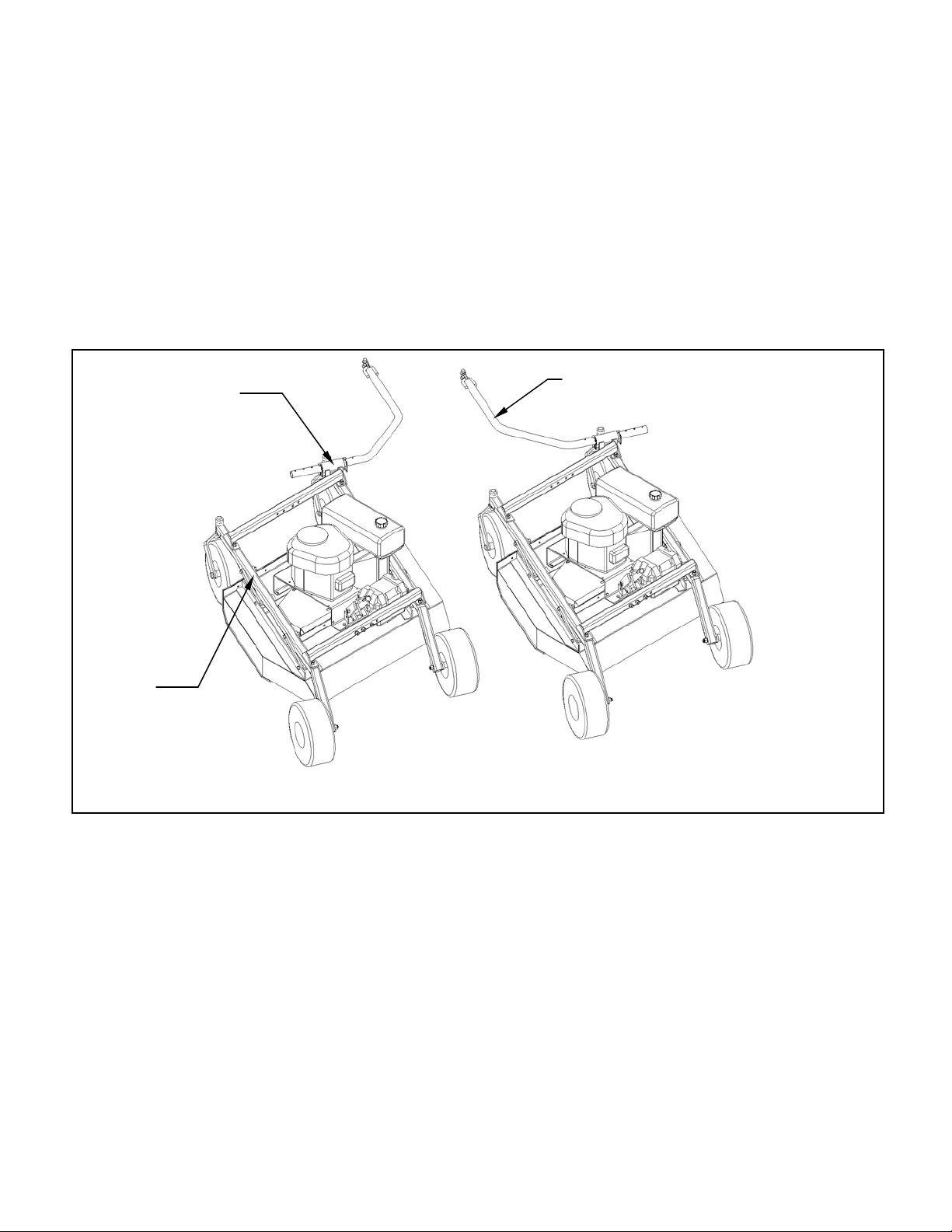

3. Install the two carrier arm assemblies in the pivot arms, which are located on the mower deck

assembly. Place the assembly so that the castered tires are on the front and the fixed tires are

on the back. See figure 2. Secure with 1/2" x 3-1/2" hex head bolts and lock nuts provided on

the pivot arms.

Note: Tighten 1/2” x 3-1/2” hex head bolts until just snug. This area needs to pivot when

adjusting the height. Under tightening can result in excessive wear and flexing. Over

tightening will make adjusting the cutting height very difficult.

Figure 2: Carrier Arm Installation

B. INSTALLATION OF CROSS BRACE TUBES AND HEIGHT ADJUST ASSY.

For this section, if your mower was purchased with an Electric Lift Kit (Part #003912), refer to

Section C of the Electric Lift Kit Owner’s Manual.

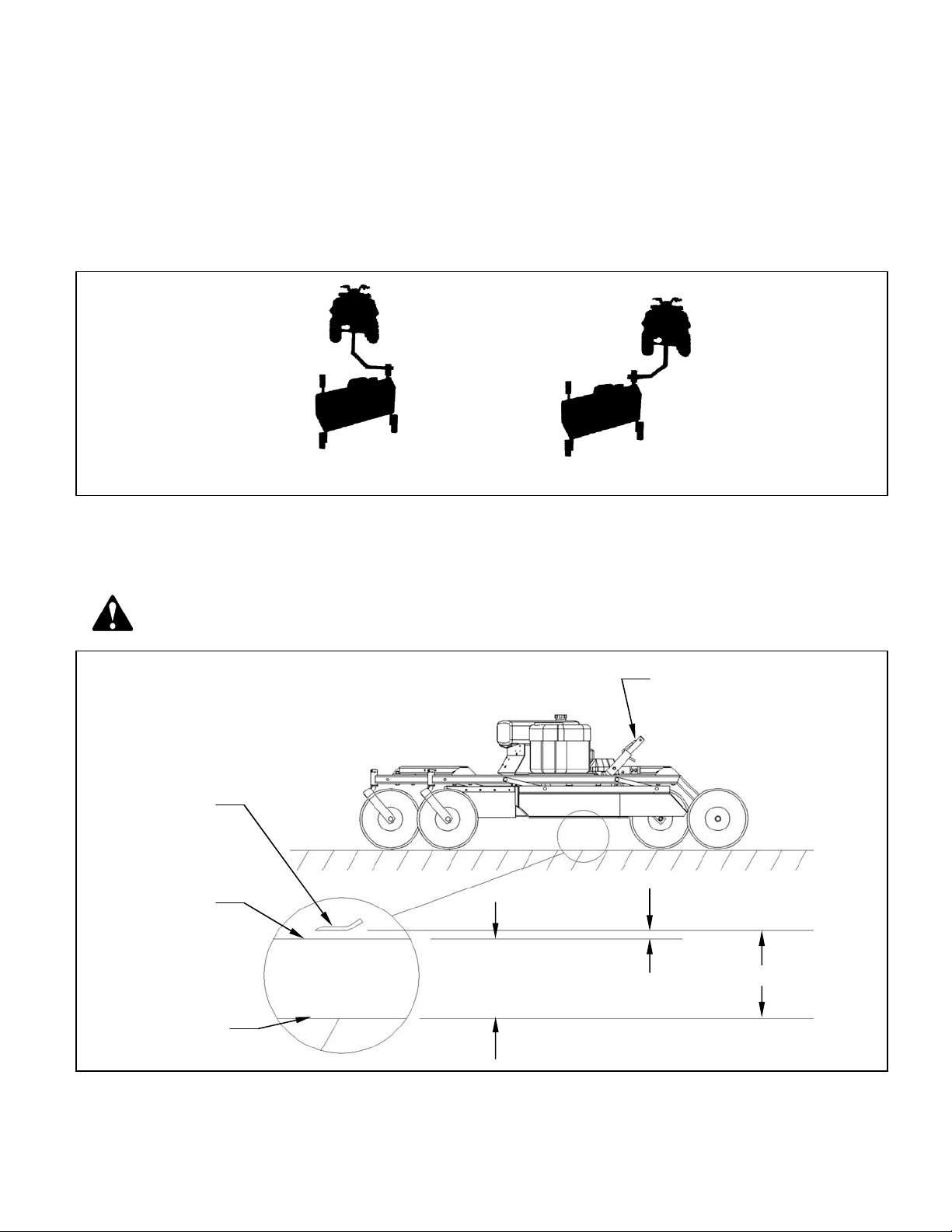

1. Remove the 1/2” x 3” hex head bolts, lock washers and nuts that are located on the top of

each carrier arm (four per carrier arm). The removed hardware will be used in step 2.

2. Install the cross brace tubes on the carrier arms with the 1/2” x 3” hex head bolts, lock washers

and nuts. Only hand tighten the hardware for this step. The support that has the height adjust

assy. fastened to it needs to be placed on the rear location. Orientate the support such that

the height adjust assy. hangs towards the engine. See figure 3.

3. Remove the 1/2” x 1” bolt and lock nut from the lower deck mount. Manually turn the screw

down towards the deck until the screw mounting flat hole lines up with the lower deck mount

hole. After achieving alignment, attach the screw mounting flat with the 1/2” x 1” hex head bolt

and secure the bolt with the provided lock nut. Do not over-tighten. This location must be able

to pivot. See figure 4.

Rear Tire Assy.

(Attach on outside for

both left and right sides)

Pivot Arm

Front (Rubber

Flap Side)

Carrier Arm

Assy.

1/2” x 3-1/2” Bolt