Innovation—Environment—People

Telephon Support + 49(0) 81 41 / 95 74 00

5307760 12/2011

1 Safety Advice

Secondary-air appliances interact with the flue gas system

and the fireplace. Therefore you should inform your

responsible building control before installation. The appliance

will only work flawlessly if the installation instructions are

followed. Only a trained expert should take care of the

installation.

2 Range of Use

Approved standard individual fireplaces (example: stoves in

living areas) with vertical flue outlet and external air supply

on the appliances back side.

3 Di ensioning the Supply Air Routing

The dimensioning of the supply air routing has to follow

effective rules, laws, guidelines and norms. In addition to the

air requirement of the fireplace, the secondary-air appliance

has an air requirement of 75 m3/h at Δp 5 Pa or 160 m3/h at

Δp 40 Pa.

4 Installation / Mounting Position

Install the casing pipe vertically on the fireplace. Align the axis

of the secondary-air appliance horizontally (see section 9 / fig.

3, side view and fig. 4, front view). Set the secondary-air

appliance as described in section 5. Now attach the

connection piece to the reception tube. Connect the oval

supply-air duct, e.g. using a flexible aluminium pipe Ø 100

mm, with the supply-air pipe of the fireplace.

5 Setting the Secondary-Air Appliance

The secondary-air appliance should be set to open at the

fireplace's minimum required draught. Please check the

documentation or the type plate of the fireplace for the

required draught. The secondary-air appliance can be

removed from the reception tube for setting. Simply push the

control wheel open and carefully pull the frame. Set the

desired value by turning the two setting weights (see section

5 / fig. 1, Adjusting the Setting Weights) and then lock them

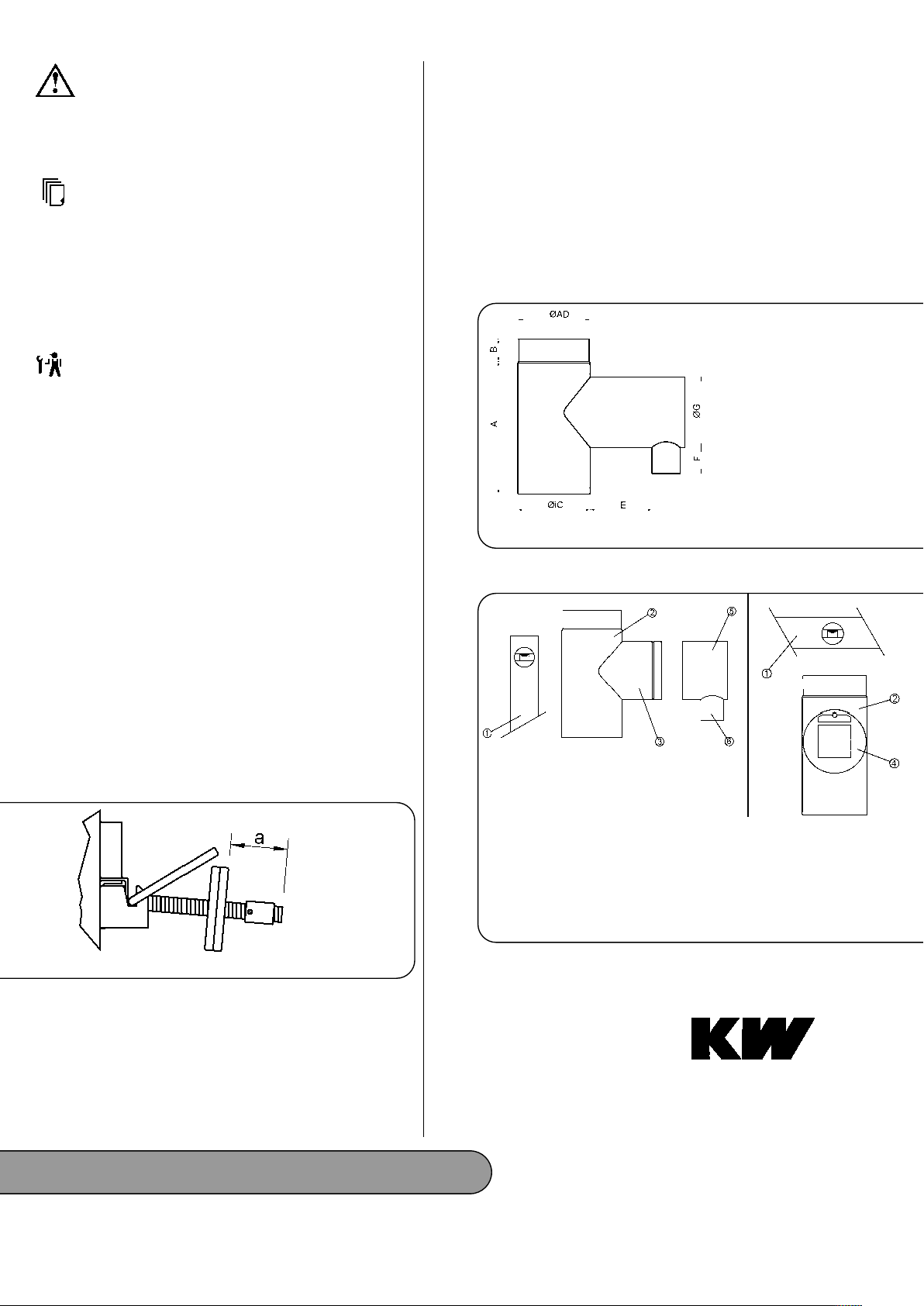

against each other. The measure "a" - 2 corresponds to the

opening value in Pa.

Exa ple: Desired opening value = 14 Pa ➞required measure

"a" = 16 mm.

Afterwards, use light pressure to let the secondary-air

appliance latch back into the reception tube. Make sure it is

aligned correctly as illustrated in section 9 / figure 4, front

view. If the opening value of the secondary-air appliance is set

too low (minimum required draught of the fireplace is not

reached), there will be disruptions of the combustion in the

fireplace!

Kutzner + Weber GmbH

Frauenstrasse 32

D-82216 Maisach

Tel.: +49 (0) 81 41 / 9 57-0

Fax: +49 (0) 81 41 / 9 57-5 00

www.kutzner-weber.de

info@kutzner-weber.de

KUTZNER + WEBER

7 Maintenance / Cleaning

Before the heating period begins, make sure that the

secondary-air appliance can move freely. If dirt or soot

has set on the control wheel, t-piece or the connection

piece, remove it carefully to ensure that the draught

regulator works flawlessly. If necessary, you may

lubricate the bearings with a drop of non-resinous oil

(e.g. sewing machine oil). Do not lubricate or grease the

bearings excessively since this only increases the build-

up of sediments. If the fireplace is used regularly, the

maintenance should be repeated during the heating

period. For this the secondary-air appliance can be

removed, as described in section 5.

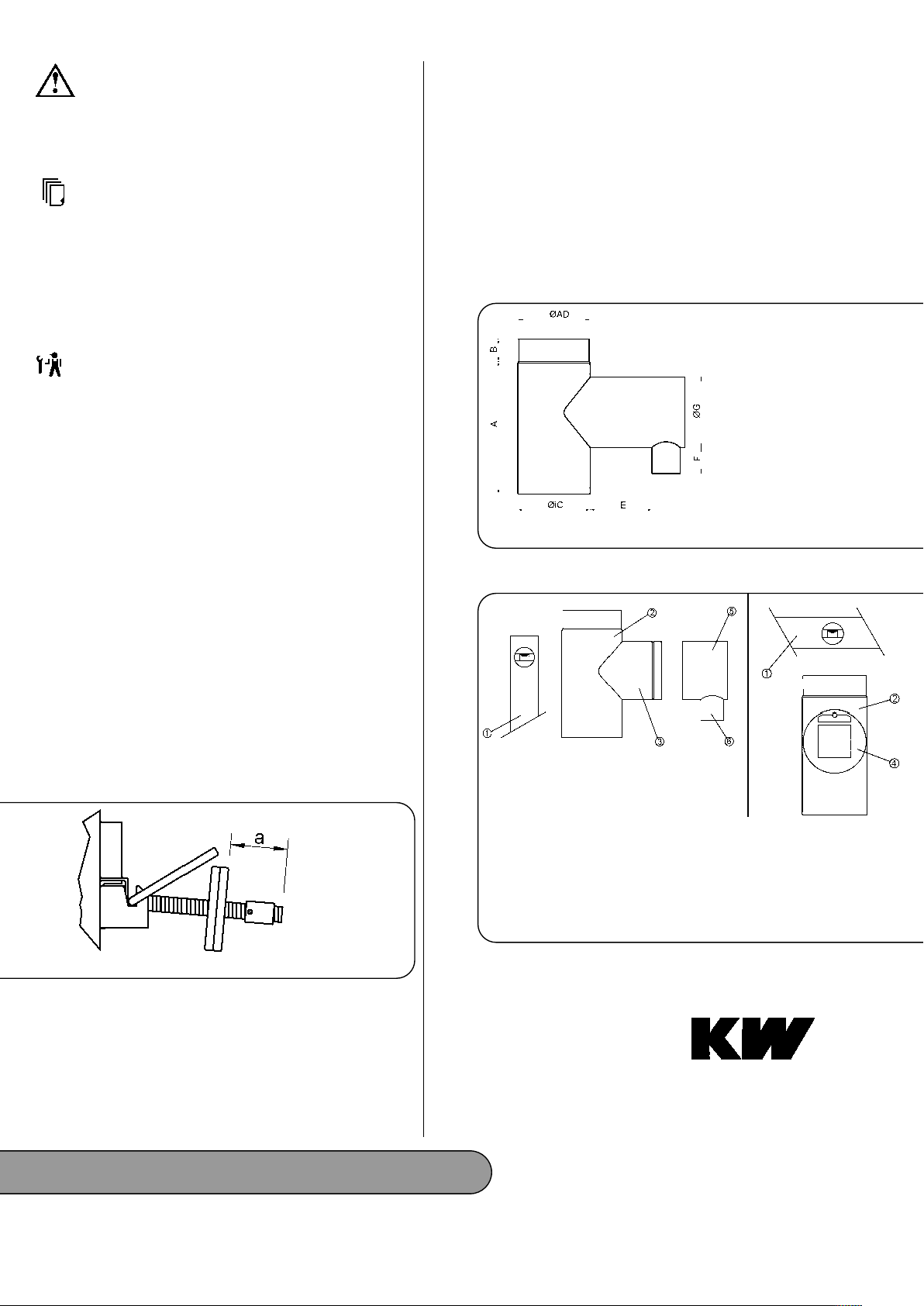

8 Di ensions

Figure 1: Adjusting the Setting Weights

6 Start-Up

After installing and setting the draught regulator you have

to check if a flawless operation of the fireplace is ensured.

In addition, the functionality of the entire flue gas evacuati-

on has to be tested (inspection and cleaning of the flue gas

system must not be impaired). In the case of an accumula-

tion or return flow of flue gasses, these must not escape in

dangerous quantities.

A = 282 mm

B = 48 mm

E = 140 to 190 mm

F = 50 mm

ØAD = 149 (+0 /-1) mm

ØG = ~150 mm

ØiC = 150 (+1/-0) mm

1 = Air level

2 = T-piece

3 = Reception tube

4 = Secondary-air appliance

5 = Connection piece

6 = Supply-air duct

a = Set value

Figure 2: Dimensions

Figure 3: Side view

Figure 4: Front view

9 Figures