5

Technical specifications

Type TIGER 500 600 700 800

Number of sections 3333

Working width, m 5.0 6.0 7.0 8.0

Number of tines 63 75 87 97

Number of tine axles 6 6 6 7

Draught requirement, kW 62 78 93 108

hp 85 105 125 145

Number of required hydraulic

outlets single-/double-acting -/3 -/3 -/3 -/3

Transport width, m 2.7 2.7 2.7 2.7

Working depth control

M = mech. H = hydr. HHHH

Number of wheels 6888

Wheel size 250 250 250 250

Weight, incl. following harrow, kg 2350 2800 3100 3500

FEATURES FOUND ON ALL TYPES:

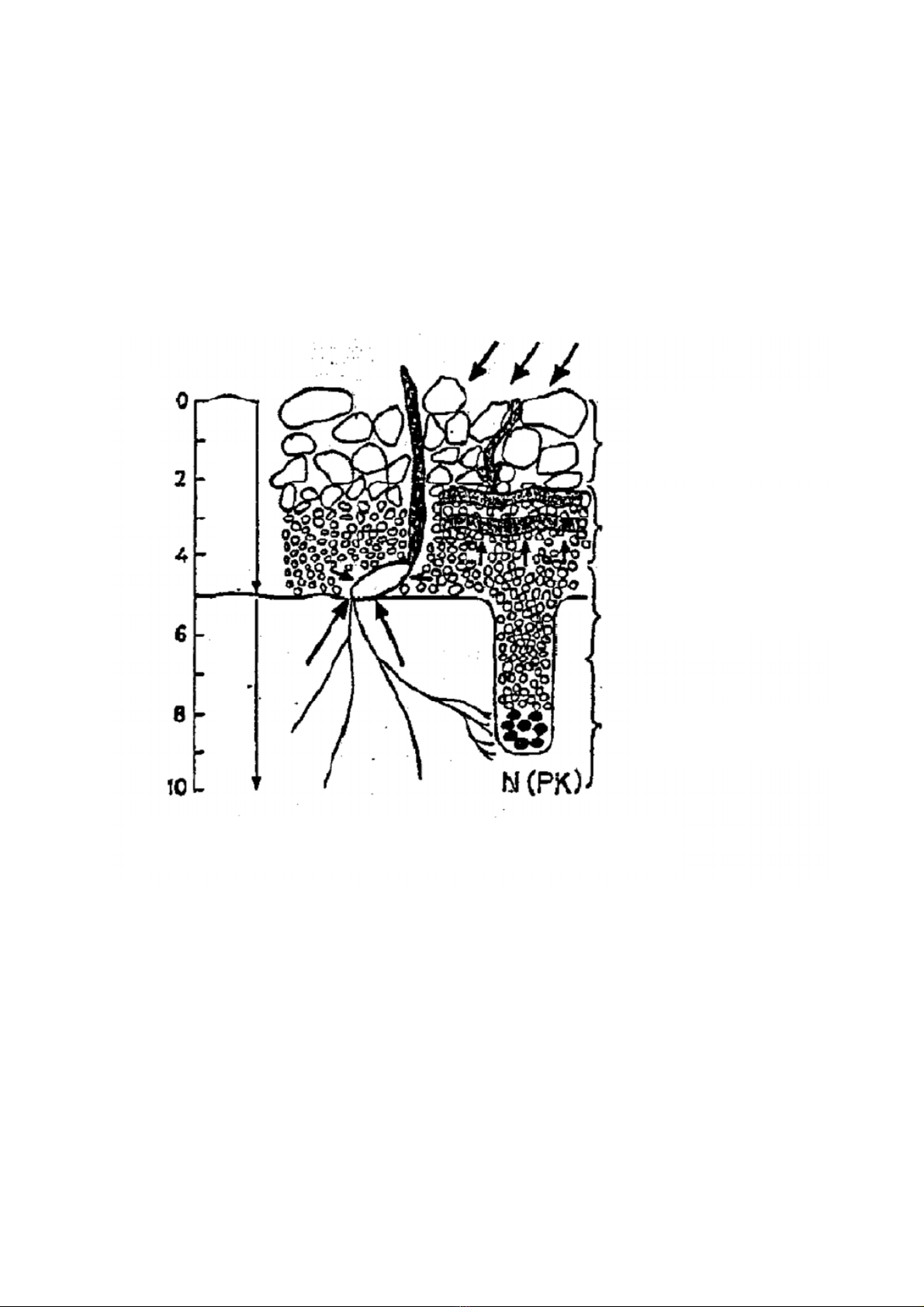

•Tine type 1045, cross-section of material 10 x 45 mm.

•Tine spacing 8 cm.

•Wheels 250/65-14,5”, diameter 685 mm, width 260 mm.

•Lights and reflectors.

•Hydraulically-controlled frontboard as standard.

OPTIONAL EQUIPMENT:

•Following harrow with a tine diameter of 12 mm.

•Spiral rollers, diameter 27 cm.

Rearboard, controlled with frontboard cylinders via linkage bars

or individually by the tractor's hydraulic system, in which case

3 double-acting hydraulic outlets are required.

•The number of rear equipment is limited to a maximum of 2 pieces

of equipment per seedbed cultivator.

•The standard frontboard can be replaced with a 20-cm high full-wide

frontboard constructed of heavy bulb flat steel profile.

•All models can be equipped with a spare wheel.