3

VD and VE

Variable area flow meters

Instructions for use and service V1.0

VD_VE_mas10_en

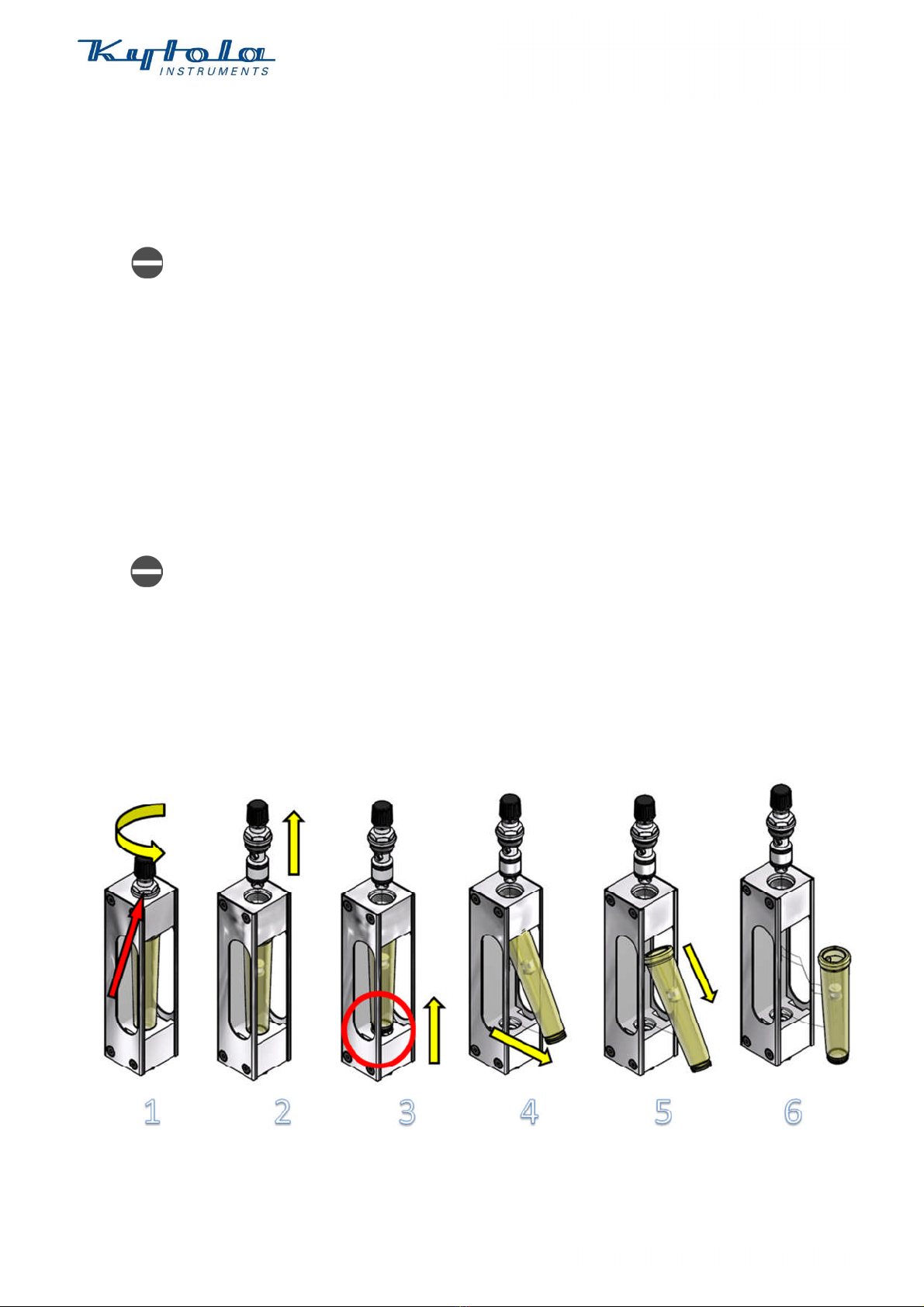

NOTE: Some floats need to be lifted upwards in the flow tube before turning the flow

tube.

CAUTION: Be careful not to damage the sealing surfaces in the lower end block.

Reassembly

To reassemble the flow meter, follow these instructions:

1 Check the cleanliness of the O-rings and sealing surfaces.

2 Replace O-rings if needed, see Chapter Change of O-rings.

3 Reassemble the flow meter parts in reverse order.

CAUTION: Check that the float is installed in the right way.

4 Place the flow tube back in its place.

5 Place the float and the guide rod attached to the valve into the flow tube.

Screw the dummy valve (model VD) or the valve (model VE) into its place.

Do this slowly not to damage the O-rings or to force them out of their

sealing grooves.

CAUTION: Do not overtighten the flow meter parts. Proper O-rings in the flow

meter do not require large tightening torque. If a leak develops, rather than tighten

the components more, replace the O-ring.

NOTE: In oil flow applications, some oil may remain in a

small pocket on the upper end of the flow tube. When

the oil warms up after start-up, it may appear as if the

meter is leaking. To avoid this, clean off the remaining

oil. For example, blow into the pocket and wipe the oil.

CAUTION: Beware not to get oil splash in your eyes.

Change of O-rings

Broken or worn-out O-rings must be removed carefully to avoid damage to the

sealing surfaces. Best results are obtained by using only fingers or soft-headed tools.

CAUTION: Do not use metallic tools.

1 Check the cleanliness of the O-rings and sealing surfaces.

2 Before installation, lightly lubricate new O-rings with silicone based

lubricant.

3 Do not damage the O-ring when moving it over threads. To protect the O-

ring, place a piece of smooth pipe over the threads or use a piece of tape or

other buffer elements.

4 Do not leave the O-ring twisted.

5 Use only factory authorized O-rings.