l-com SRWQ100-YL105-9001 User manual

1

RESIDUAL CHLORINE SENSOR

(WATER QUALITY ANALYSIS)

User Manual for SRWQ100-YL105-9001

Thank you for choosing L-com product. To ensure safe, accurate performance and product

longevity, please take a moment to familiarize yourself with this manual before powering the

device. Please keep it handy for future reference. In case of any questions regarding the

installation or use of product, please call us at 800.341.5266.

Reach out to us at customerservice@l-com.com and visit our website at www.l-com.com

M_SRWQ100-YL105-9001_05/2022_R1.0

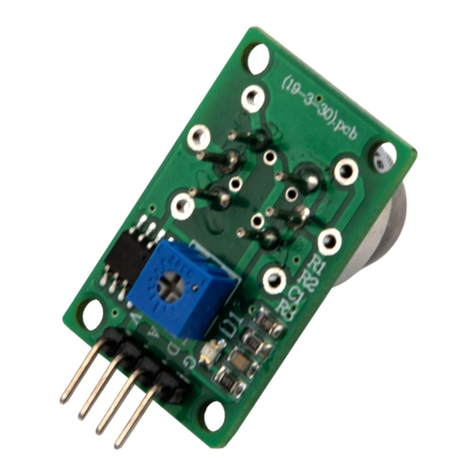

Signal Line

2

Technical Indicators

Instructions Before Use

The membrane head is fragile, it cannot be repaired in case of damage.

Before using the electrode, gently remove the protective cover. Put electrode in the

solution to test for polarization for more than 6 hours. For more details, refer Polarization

Section.

If no electrolyte is in the membrane, the measurement will be inaccurate or fluctuating.

After adding membrane head with electrolyte, do not store the electrode in air for more

than 30 mins.

Clean and calibrate the membrane head timely. Presence of dirt, adhesive or encrust on

the membrane head can cause inaccuracy in measurement.

Make sure no bubbles are present in membrane head for accurate results.

Extension, cutting, joint and forcefully pulling signal line may cause inaccurate results.

Electrode Wiring

Please follow the instructions carefully, wrong wiring will damage the product completely.

Examine all the wiring carefully in the system. Make sure wiring is complete before

switching ON the power.

It is strictly forbidden that RS485A line and RS485B line should not touch the power line.

It will permanently damage the communication of the electrode.

Measuring Range 0.00 20.00 mg/L (ppm)

Accuracy 2% or ± 10 ppb HOCI

Temperature Range 0 60.0 ˚C

Response Time 90% less than 90 seconds

Pressure Range 0 1 bar

Shell Material ABS, 316

Output RS485, 4 20 mA

Power Supply 9 30 VDC (Recommend 12V)

Pipe Thread M 39*1.5

Cable Length 5m or customized

Protection Grade IP68

3

Procedure to Add Electrolyte and Replace the Membrane Head

Kindly check the new membrane head is added with electrolyte before use.

It is recommended to replace the electrolyte every three months. Also, it is subjected to

the specific use of the measured medium and electrode.

If the electrode signal is abnormal (long response time, mechanical damage, too large in

zero oxygen water, too large or too small in air etc), the membrane head needs to be

replaced. The normal oxygen membrane is replaced every 6 to 12 months, and the

toughened oxygen membrane is replaced every 18 to 24 months.

Follow the below procedure to replace the membrane head and add electrolyte:

Disconnect the power supply.

Turn the membrane head

counter-clockwise. Remove the

membrane head smoothly.

Pour the residual electrolyte

inside the membrane head to

the waste solution pool.

Tilt the membrane head and

the electrolyte bottle is

vertically downward. Gently

squeeze the electrolyte

bottle, so that the electrolyte

slowly fills into the mem-

brane head until it is full.

Slowly turn the membrane

head clockwise onto the

inner core of the electrode

until the liquid beads flow

out. Tighten and loosen the

membrane head 3 times to

completely burst the bubbles

and make the membrane

head close to the electrode

cathode.

Electrode Outlet

4

Electrode Polarization

Polarization Method: Put the electrode in the solution to be tested. Connect the power

supply. Polarization starts as soon as the power is turned ON.

Polarization Cases: The electrodes needs to be polarized in the following cases:

When the electrode is first used, polarize it for more than 6 hours.

When the membrane head or electrolyte is replaced, polarize it for more than 6 hours.

If electrode is disconnected from the power line. See the below table for polarization time:

Electrode Calibration

The electrode has been calibrated before shipment, user can directly use it. Online

monitoring of the measured medium should keep a constant flow rate, range 15 - 30 L/h.

The calibration of dissolved oxygen electrode is performed by zero oxygen calibration and

full scale calibration, Before the calibration, ensure that the cable is connected to the

instrument and the electrode has polarized for more than 6 hours.

Users are recommended to calibrate the electrode every 1 to 2 months.

Electrode Installation

It is recommended chlorine electrode to be installed in the flow cell for more stable and accurate

measurement. If electrode is installed in the pipe, the right angle should be 15°-165°.

Power OFF Time t1 (Minute) Minimum Polarization Time t2 (Minute)

t1 ≤ 5 2 * t1

5 < t1 ≤ 15 4 * t1

15 < t1 ≤ 30 6 * t1

t1 > 30 360

5

During Immersion Installation

During installation procedure, there will be frequent dirt on electrode, clean it regularly.

Measuring value is not stable.

Different insertion depths affects the measured value.

The position of the electrode must be above the sediment.

Electrode Communication

Default Communication Instructions:

Data starting at 0x represents hexadecimal.

The check code is 16CRC, the low byte is in the front and the high byte is in the back.

Floating point number occupy four bytes.

Communication Description (Factory Default):

Host Computer Transmission Format:

Function Code Description:

This product supports 03,06,16 and other common function codes.

The output register uses 16 function codes when writing double word data or writing

multiple data in batches.

Baud Rate 9600 (Default)

Data Bit 8

Stop Bit 1

Check Bit No

Address 1 (Default)

Data Type Description Remarks

Integer 16-Bit

Integer

The high-low bytes of word

component are not reversed

Ex: O x 0032 to decimal

number is 50

Floating

Point

Number

(CDAB)

3412

The high-low word of the

double-byte component is

reversed, but the high-low

byte of the word is not

reversed.

Example: 72 37 41 DB transfer to

floating point number.

CDAB change order is ABCD.

Eg: 41 DB 72 37 transfer to floating

point is 27.4

03 Read single or multiple registers

06 Write single register

16 Write multiple registers

6

ID

Address

Func-

tion

Code

Register Start

Address

Qty. Of

Registers

CRC16

High

Byte

Low

Byte

High

Byte

Low

Byte

High

Byte

Low

Byte

Eg: Read

Measured

Value

0x01 0x03 0x00 0x01 0x00 0x02 0xCB 0x95

Eg: Read

Temp. Value

0x01 0x03 0x00 0x03 0x00 0x02 0x0B 0x34

ID

Address

Func-

tion

Code

Qty of

Registers

CRC16 Read Register Data in

Hexadecimal Floating Point

Number

CDABHigh

Byte

Low

Byte

Eg:

Measured

Value

Return

0x01 0x03 0x04 0x2C 0x81 0x40 0x91 0xE7 0x52

Eg: Temp.

Value

Return

0x01 0x03 0x04 0x72 0x37 0x41 0xDB 0x8E 0x20

Slave Computer Response Format:

Note: 72 37 41 DB transfer to floating point number, CDAB change order is ABCD,

i.e. 41 DB 72 37 transfer to floating point is 27.4.

Read Integer

Host Computer Transmission Format:

Slave Computer Response Format:

ID

Address

Function

Code

Register Start

Address

Qty. Of

Registers

CRC16

High

Byte

Low Byte High

Byte

Low

Byte

High

Byte

Low

Byte

Eg: Read

Warning

Status

0x01 0x03 0x00 0x07 0x00 0x01 0xCB 0x35

ID

Address

Function

Code

Qty of

Registers

Read Register Data in

Hexadecimal Floating

Point Number

CRC16

ABHigh

Byte

Low

Byte

Eg: Measured

Value Return

0x01 0x03 0x02 0x00 0x00 0x44 0xB8

Read Floating Point Number

Host Computer Transmission Format:

7

ID Func-

tion

Code

Register

Start

Address

Qty. Of

Registers

Qty

Of

Byte

CRC16 Register Data in

Hexadecimal Floating

Point Number

High

Byte

Low

Byte

High

Byte

Low

Byte

CDABHigh

Byte

Low

Byte

Eg:

Write

Value

Offset

0x01 0x10 0x00 0x12 0x00 0x02 0x04 0x

00

0x

00

0x

3F

0x

80

0x2A 0x63

Write Floating Point Number

Host Computer Transmission Format:

Slave Computer Response Format:

Note: The measured value if offset by 1.00, floating point number 1.00 coverts to

hexadecimal 0X3F800000, transpose the high and low positions 0X00003F80 and write

0X0012.

Write Integer

Host Computer Transmission Format:

Slave Computer Response Format:

Note: Change the local computer address 1 to address 2 and write the hexadecimal

number 0X00 02 into register 0X00 19.

ID

Address

Function

Code

Register Start

Address

Qty. Of

Registers

CRC16

High

Byte

Low

Byte

High

Byte

Low

Byte

High

Byte

Low

Byte

Eg: Return

Value Offset

0x01 0x13 0x00 0x12 0x00 0x02 0xCD 0xE1

ID

Ad-

dress

Func-

tion

Code

Register Start

Address

Register Data in

Hexadecimal Integer

CRC16

High

Byte

Low

Byte

ABHigh

Byte

Low

Byte

Eg: Write

Device

Address

0x01 0x06 0x00 0x19 0x00 0x02 0xCC 0xD9

ID

Ad-

dress

Func-

tion

Code

Register Start

Address

Register Data in

Hexadecimal Integer

CRC16

High

Byte

Low

Byte

ABHigh

Byte

Low

Byte

Eg: Device

Return

Address

0x01 0x06 0x00 0x19 0x00 0x02 0xCC 0xD9

8

Name Hosting

Number

Data

Type

Length Read/

Write

Description

Measurements 0x 00 01 Floating

Point 2Storage location for measured value

Temperature

Measurement 0x 00 03 Floating

Point 2Storage location for measured

temperature

Current Output

Value 0x 00 05 Floating

Point 2Output current based on DO

measurements

Warning 0x 00 07 Integer 1

01: Measurement exceeds the

upper limit;

02: Measurement exceeds the

lower limit;

03: Temperature exceeds the

upper limit;

04: Temperature exceeds the

lower limit

Upper Limit Of

Measurement 0x 00 0A Floating

Point 2

Upper limit of measured value

(20mA corresponding value)

Address Description

Calibration Instructions

Before Calibration:

Write the residual chlorine calibration value to the sensor before calibration.

If the calibration is 1.0 mg/L, write the current data to the 0x24 register (Floating point

1.0 to hexadecimal number is 3F800000, high and low transposition is 00003F80).

Send command : 0110 00 24 00 02 04 00 00 3F 80 E0 14.

The First Point - Zero Calibration:

The sensor is cleaned and dried and put into the residual chlorine 0 mg/L solution.

Send command: 01 03 00 66 00 01 64 15.

After the measured AD value is stable, read the AD value in the 0x66 register;

Write the instruction to confirm the calibration to the 0x3E register.

Send command : 01 06 00 3E 00 FF A8 46.

The Second Point - High Point Standard Calibration:

The sensor is cleaned and dried and put into the residual chlorine 1.0 mg/L solution.

Send command: 01 03 00 66 00 01 64 15.

After the measured AD value is stable, read the AD value in the 0x66 register;

Write the instruction to confirm the calibration to the 0x3F register.

Send command: 01 06 00 3F 00 FF F9 86.

The residual chlorine sensor generally only needs to calibrate the high point, and may

also calibrate both of the high and low points.

9

Name Hosting

Number

Data

Type Length Read/

Write Description

Lower Limit Of

Measurement 0x 00 0C Floating

Point 2

Lower limit of measurement value

(4mA corresponding value)

Upper

Temperature Limit 0x 00 0E Floating

Point 2Upper temperature limit

Lower

Temperature Limit 0x 00 10 Floating

Point 2Lower temperature limit

Measured Value

Offset 0x 00 12 Floating

Point 2Adjust measurement

Temperature

Offset 0x 00 14 Floating

Point 2Adjust temperature value

Damping

Coefficient 0x 00 16 Integer 10-10

Device Address 0x 00 19 Integer 11-255

Baud Rate 0x 00 1A Integer 1

0=2400 , 1=4800, 2=9600,

3=19200, 4=38400

Restore Default 0x 00 1B Integer 1

Standard solution

value 0x 00 30 Floating

Point 2

pH compensation 0x 00 26 Floating

Point 2

Manual

temperature 0x 00 3A Floating

Point 225°C

Zero calibration 0x 00 3E Integer 1

Slope calibration 0x 00 3F Integer 1

Measured AD 0x 00 66 Integer 1

10

Sr.

No. Function Send command Return command Remarks

1

Read

measured

value

01 03 00 01 00 02 95 CB 01 03 04 2C 81 40

91 52 E7

The 2C814091 change order

is 40912C81 and its floating

point is 4.53

2

Read

temperature

measurement

01 03 00 03 00 02 34 0B 01 03 04 72 37 41

DB 20 8E

The 723741DB change or-

der is 41DB7237and its

floating point is 27.4

3Read current

output value 01 03 00 05 00 02 D4 0A 01 03 04 00 00 41

40 CB 93

The 00004140 change order

is 41400000 and its floating

point is 12.00

4Read warning 01 03 00 07 00 01 35 CB 01 03 02 00 00 B8

44 0000 is the current state

5

Write

measurement

mode

01 06 00 08 00 01 C9 C8 01 06 00 08 00 01

C9 C8

Set to residual

chlorine mode

6

Write

upper limit of

measurement

01 10 00 0A 00 02 04 00

00 41 20 42 58

01 10 00 0A 00 02

61 CA

The upper

measurement limit is set to

10.00

7

Write lower

limit of

measurement

01 10 00 0C 00 02 04 00

00 3F 80 E3 AA

01 10 00 0C 00 02

81 CB

The lower

measurement

limit is set to 1.00

8

Write upper

temperature

limit

01 10 00 0E 00 02 04 00

00 42 C8 43 15

01 10 00 0E 00 02

20 0B

The upper

temperature limit is

set to 100.00

9

Write lower

temperature

limit

01 10 00 10 00 02 04 00

00 40 A0 C3 1B

01 10 00 10 00 02

40 0D

The lower temperature

limit is set to 5.00

10

Write

measured

value offset

01 10 00 12 00 02 04 00

00 3F 80 63 2A

01 10 00 12 00 02

E1 CD Set to 1.00

11

Write

temperature

offset

01 10 00 14 00 02 04 00

00 3F 80 E3 00

01 10 00 14 00 02

01 CC Set to 1.00

12 Write damping

coefficient 01 06 00 16 00 01 A9 CE 01 06 00 16 00 01

A9 CE Set to 1

Common Instruction Examples

11

Sr.

No. Function Send command Return command Remarks

13 Write device

address 01 06 00 19 00 02 D9 CC 01 06 00 19 00 02

D9 CC Set to 2

14 Write baud

rate 01 06 00 1A 00 00 A8 0D 01 06 00 1A 00 00

A8 0D Set to 2400

15 Write restore

default 01 06 00 1B 00 FF B9 8D 01 06 00 1B 00 FF

B9 8D

Factory default values

are restored after sent

16 Write manual

temperature

01 10 00 3A 00 02 04 00

00 41 A0 40 EC

01 10 00 3A 00 02

61 C5 Set to 20.0

17 Write zero

calibration 01 06 00 3E 00 FF A8 46 01 06 00 3E 00 FF

A8 46

Confirm to calibration

zero

18 Write slope

calibration 01 06 00 3F 00 FF F9 86 01 06 00 3F 00 FF

F9 86

Confirm to calibration

slope

19 Read

measuring AD 01 03 00 66 00 01 64 15 01 03 02 2E E0 A4

6C

2EE0 turns to integer

12000

Maintenance And Storage

The electrode should be cleaned regularly.

Be careful while disassembling and rinsing the chlorine membrane,

Do not wipe chlorine membrane on the electrode with filter paper or sandpaper.

If the membrane head is fouled and clogged, the electrolyte is dry, lack or is

contaminated. Stop using the membrane and its head should be removed and cleaned.

After cleaning the electrode, replace the membrane head, add electrolyte. After

long-term storage, it needs to be polarized and calibrated before use.

The cable connector must be kept clean, dry, free from moisture, water, acids, alkalis or

salts, etc.

If water supply is cut off or electrode is not used on site, the electrode should be taken

out, cleaned and covered with protective sleeve containing water for preservation.

If the electrode is not used and stored for a long time, remove the electrode, disconnect

the cable, drain the electrolyte, thoroughly clean the anode and the cathode with

deionized water at 30 °C-40 °C, dry it and put on the protective cover. Place it in a dry

place for storage.

12

Troubleshooting

If the measurement is not accurate, its mostly because the condition of residual chlorine

electrode has changed. So it is necessary to check whether the residual chlorine

electrode is in good condition or not.

The residual chlorine electrode is not easy to damage, generally the membrane head

may has dirt ,the electrolyte maybe polluted or lost etc., user needs to replace the

membrane head or add / change electrolyte.

If the value of the instrument is too large, too small or no change, check whether the

electrolyte is dry, missing or contaminated. If the above conditions occur, change / add

the electrolyte.

MODBUS Troubleshooting

Problem Possible reason Solution

Modbus no

response

The baud rate, or stop bit does not match

the Modbus master settings

Verify that the settings match

the Modbus master device set-

tings, and verify that the Modbus

master device parity check is set

to None.

Rs232 or RS485 cable is faulty Replace / repair cables

No network offsets and terminations, or

network offsets and terminations are not

suitable.

Check the termination or

offset settings for all

network devices. Only the end-

points of the network should be

turned on and terminated, and

there should be only a point on

the network to provide an offset.

The slave address is incorrect, or the slave

address is the same as the address of

another bus device

Verify that all addresses are

unique and are between 1 and

247.

Modbus

abnormal

response

Register not supported Verify that the register is

supported.

Incorrect data type

Verify that the requested

register data type matches the

Modbus master device request.

For example, user cannot ac-

cess a floating point data using

2-byte integer data. When a

floating point data

(2 registers / 4 bytes) is request-

ed, two registers must be re-

quested at the same time.

Table of contents

Other l-com Accessories manuals