Table of Content

1.0 Safety ..................................................................................................................................................................................................... 1

1.1 How to use the Manual ................................................................................................................................. 2

1.1.1 Introduction ............................................................................................................................................................................... 2

1.1.2 Chapter summary ................................................................................................................................................................... 2

1.2 Responsibility ................................................................................................................................................ 2

1.2.2 Responsibility of the users ................................................................................................................................................... 3

1.2.3 Preventative Maintenance .................................................................................................................................................... 4

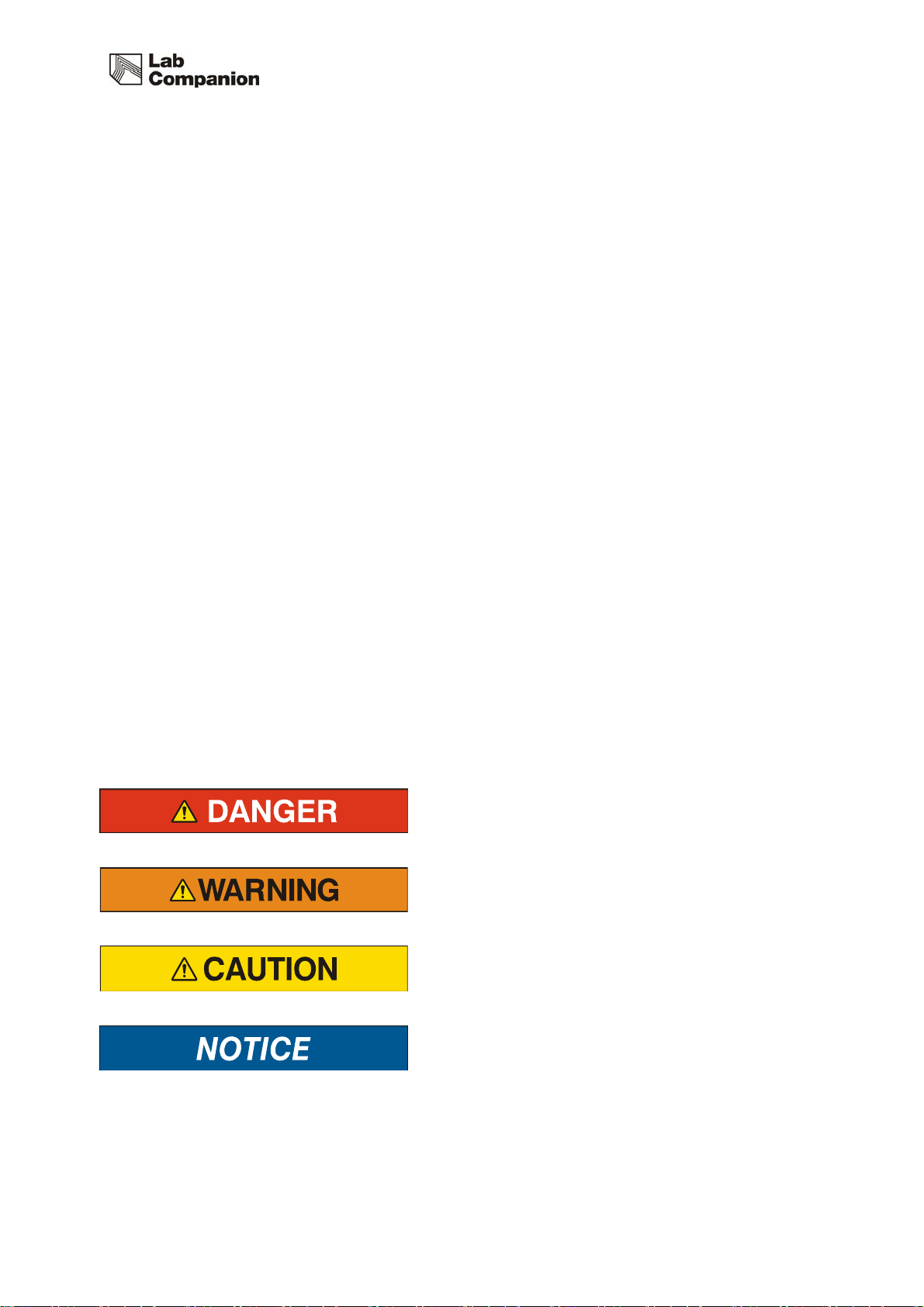

1.3 Symbols used in this Manual ........................................................................................................................ 4

1.3.1 Signal word panels ................................................................................................................................................................. 4

1.3.2 Safety symbols .......................................................................................................................................................................... 5

1.3.3 Non-safety symbols ................................................................................................................................................................ 7

1.4 Where to Locate Safety Labels on product. .................................................................................................. 7

1.5 Precautions for your product ...................................................................................................................... 7

1.5.1 Warning statements ............................................................................................................................................................... 8

1.5.2 Caution statement ................................................................................................................................................................... 9

2.0 Functional Description ................................................................................................................................................................... 11

2.1 Introductions ............................................................................................................................................... 12

2.2 Features .................................................................................................................................................... 12

2.3 Structure ..................................................................................................................................................... 13

3.0 Installation .......................................................................................................................................................................................... 15

3.1 Components ............................................................................................................................................... 16

3.2 Environmental setting ................................................................................................................................. 17

3.3 Preparing before installation ..................................................................................................................... 17

3.4 Power Supply ............................................................................................................................................. 18

3.5 Operation ................................................................................................................................................... 19

3.5.1 Confirmation in advance .................................................................................................................................................. 19

3.5.2 End operation of the equipment .................................................................................................................................... 19

4.0 Operation ........................................................................................................................................................................................... 20

4.1 Function of control panel ............................................................................................................................ 21

4.2 Control structure ........................................................................................................................................ 22

4.3 Basic operation .......................................................................................................................................... 23

4.3.1 Operation ............................................................................................................................................................................... 23

4.3.2 Temperature control ........................................................................................................................................................... 23

4.3.3 Controller Lock .................................................................................................................................................................... 24

4.4 TIMER Function ........................................................................................................................................ 24

4.4.1 TIMER ON setting .............................................................................................................................................................. 24

4.4.2 TIMER OFF Setting ........................................................................................................................................................... 25

4.4.3 Terminate TIMER ................................................................................................................................................................ 25

4.5 Configuration ............................................................................................................................................. 25

4.6 System Configuration ................................................................................................................................ 26

4.6.1 Auto Tune .............................................................................................................................................................................. 27