7

4. Preparation and Start-up

4.1 Before starting your equipment, the unit must be placed horizontally on a solid, flat floor, and

elevated and leveled with four foot blocks. The foot blocks are provided to level as well as “fix”the

unit firmly on the floor. To allocate the blocks in position, please do strictly follow the procedures:

4.1.1 Lift the front below cover and take it off. (If ZWY-211B/111B, please skip to “Section

4.1.2”.)

4.1.2 Unscrew up the adjusting bolt on the front-left corner.

4.1.3 There is one hole on each of the other three corners of base of the unit, locate each of

them.

4.1.4 Tilt or push the unit from its front side, and at the same time, another person is needed to

lay the foot block underneath the hole, whose hands must be off the unit before the unit is

laid down! Do be careful of your hand!

4.1.5 Lay down the unit and see whether the tip of the block sits firmly in the hole. If not, please

re-do the “Section 4.1.4”again. Then lay the other one on the same side.

4.1.6 Lay the rest two blocks on the back side of the unit.

4.1.7 Keep unscrewing / screwing the adjusting bolt on the front-left corner with the spanner

until the unit is elevated leveled and sits firmly on the four blocks.

4.2 The shaking mechanism of all reciprocal shaking incubator (ZWF-111/211) needs filled up with

Lithium base oil before operation. To do so, remove the front below cover of the outer case, open

the lid, and remove the shaking tray so that the whole shaking mechanism can be seen. Then

pump the oil by pushing down the bar handle, until seeing the oil overflowing from the holes on the

shaking mechanism. Pump the oil frequently to ensure smooth shaking movement.

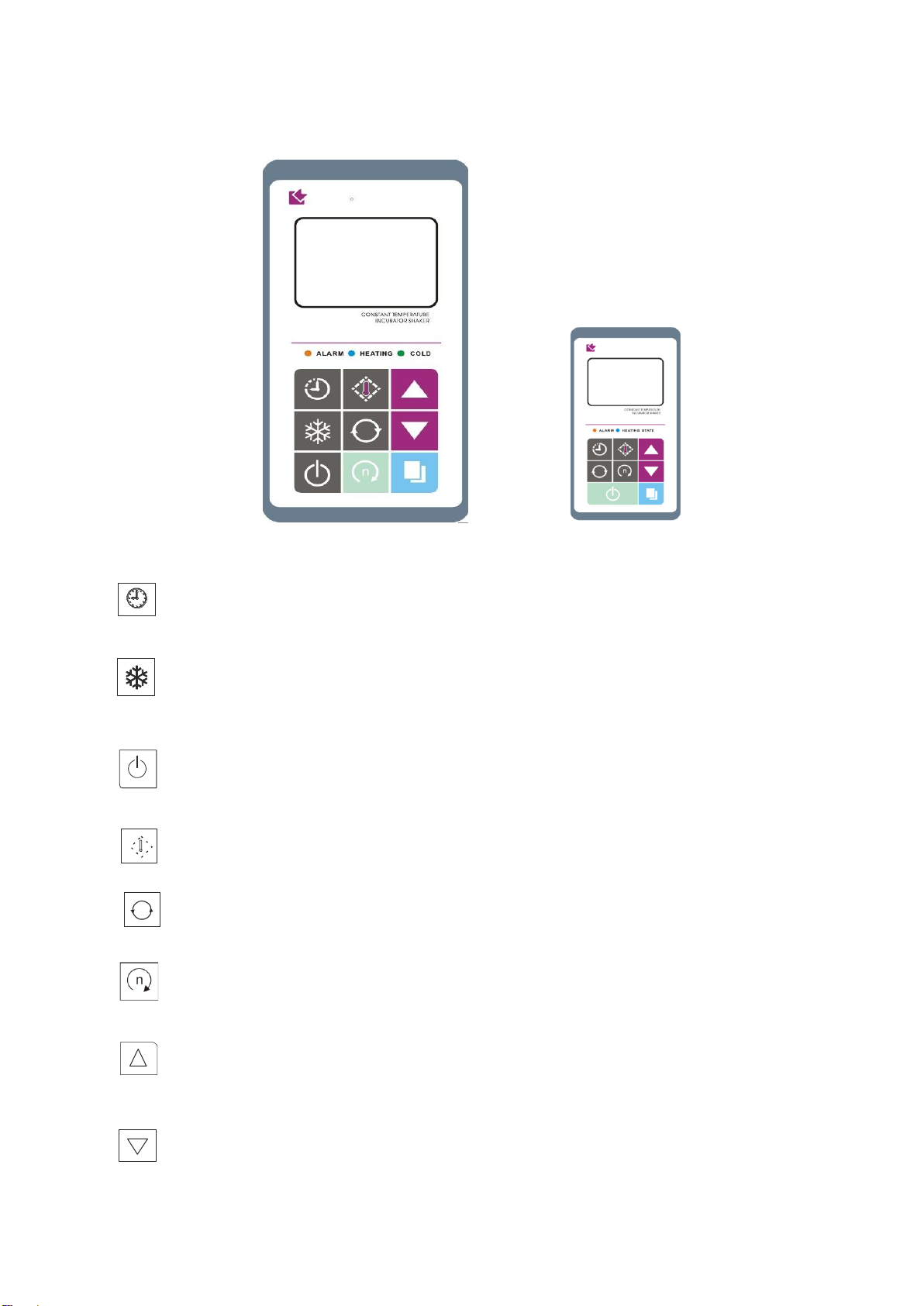

4.3 Turn the main switch which is located on the right side of the unit, power is applied to the

Unit and the LCD display shows:

-Incubator Shaker

-Pre-set Temperature

-Pre-set Speed

-Pre-set Time

4.3 The screen in turns displays the operating parameter stored in the equipment:

Preset temperature; Preset speed; Preset time; Real temperature.

And now, the microprocessor system has started controlling the temperature according to the

preset value.

Safety instruction!

Please be sure to follow the instructions, which are really important for

your safety.