5 Installing on a Rack

This section describes what to do before installing on a rack and how to rack

mount.

Before Installing on a Rack

Before installing on a rack, be sure that the environment is

within the recommended range:

Operating temperature range +5 to +45 Deg. Centigrade

Operating humidity range 5 to 65 % RHL, non-condensing

Storage temperature range -20 to +70 Deg. Centigrade

Storage humidity range 5 to 95% RHL, non-condensing

CAUTION!!

When installing on a 19" rack, avoid hazards by taking care

that:

1

It is located within the recommended environmental

conditions, as the operating ambient temperature of a

closed or multi unit rack assembly may exceed the room

ambient temperature.

2

Once rack mounted, enough air will still flow around the

machine.

3

The machine is placed straight in the correct horizontal

position.

4

You do not overload the circuit(s). When connecting the

machine to the supply circuit, overloading the circuits might

have a detrimental effect on overcurrent protection and

supply wiring. Refer to the appropriate nameplate ratings for

information. For example, for fuse replacement, see the

value printed on the product label.

5

The machine is earthed (grounded) in a reliable way and is

connected only to an electricity socket with grounding. Pay

particular attention to situations where electricity is supplied

indirectly (when the power cord is not plugged directly into the

socket in the wall), for example, when using an extension

cable or a power strip, and that you use only the power cord

that is supplied with the machine.

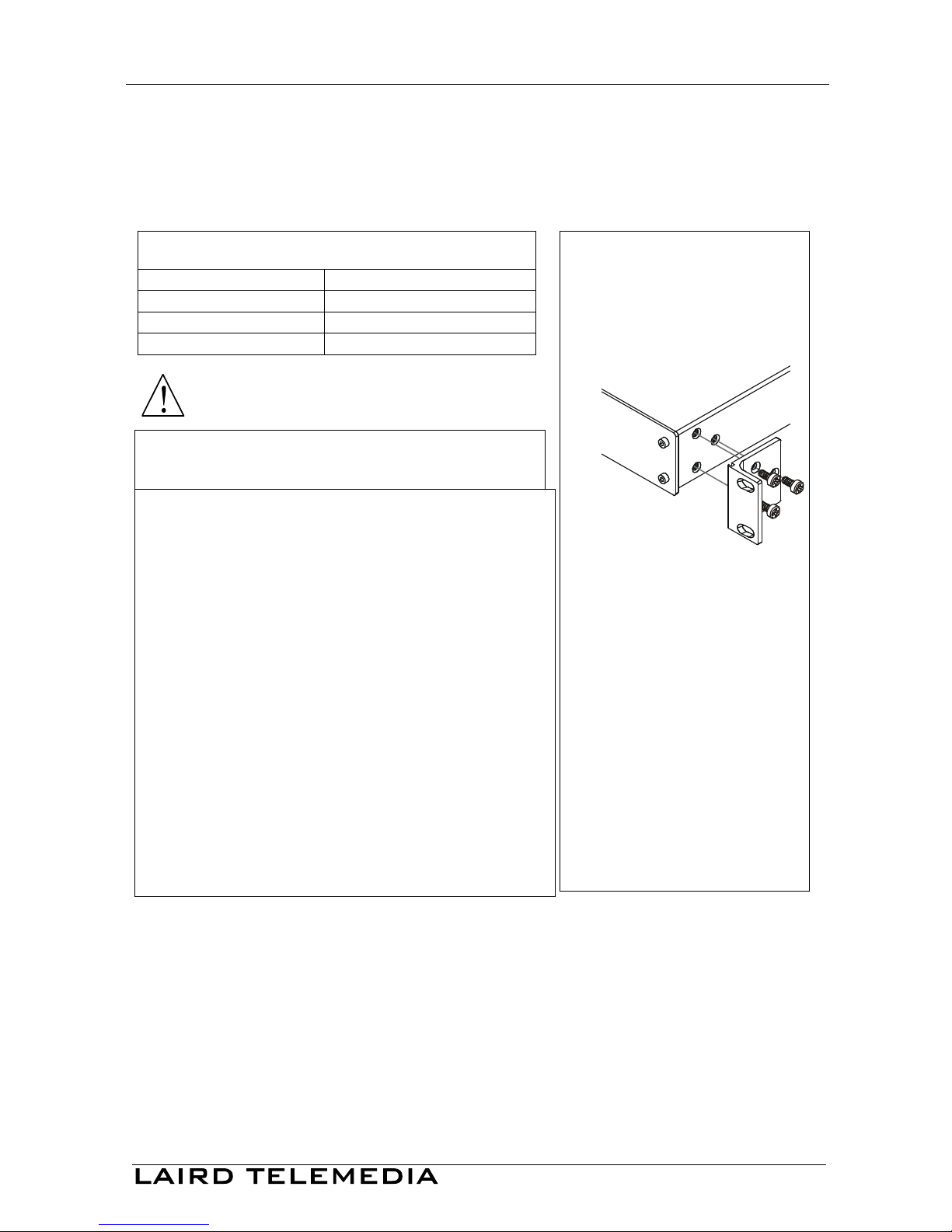

How to Rack Mount

To rack-mount the machine:

1

Attach both ear brackets to the

machine. To do so, remove the

screws from each side of the

machine (3 on each side), and

replace those screws through

the ear brackets.

2

Place the ears of the machine

against the rack rails, and insert

the proper screws (not provided)

through each of the four holes in

the rack ears.

Note that:

In some models, the front panel

may feature built-in rack ears

Detachable rack ears can be

removed for desktop use

Always mount the machine in the

rack before you attach any cables or

connect the machine to the power