Installation / Operation / Maintenance Manual 10/28/2019

9

TableofContents

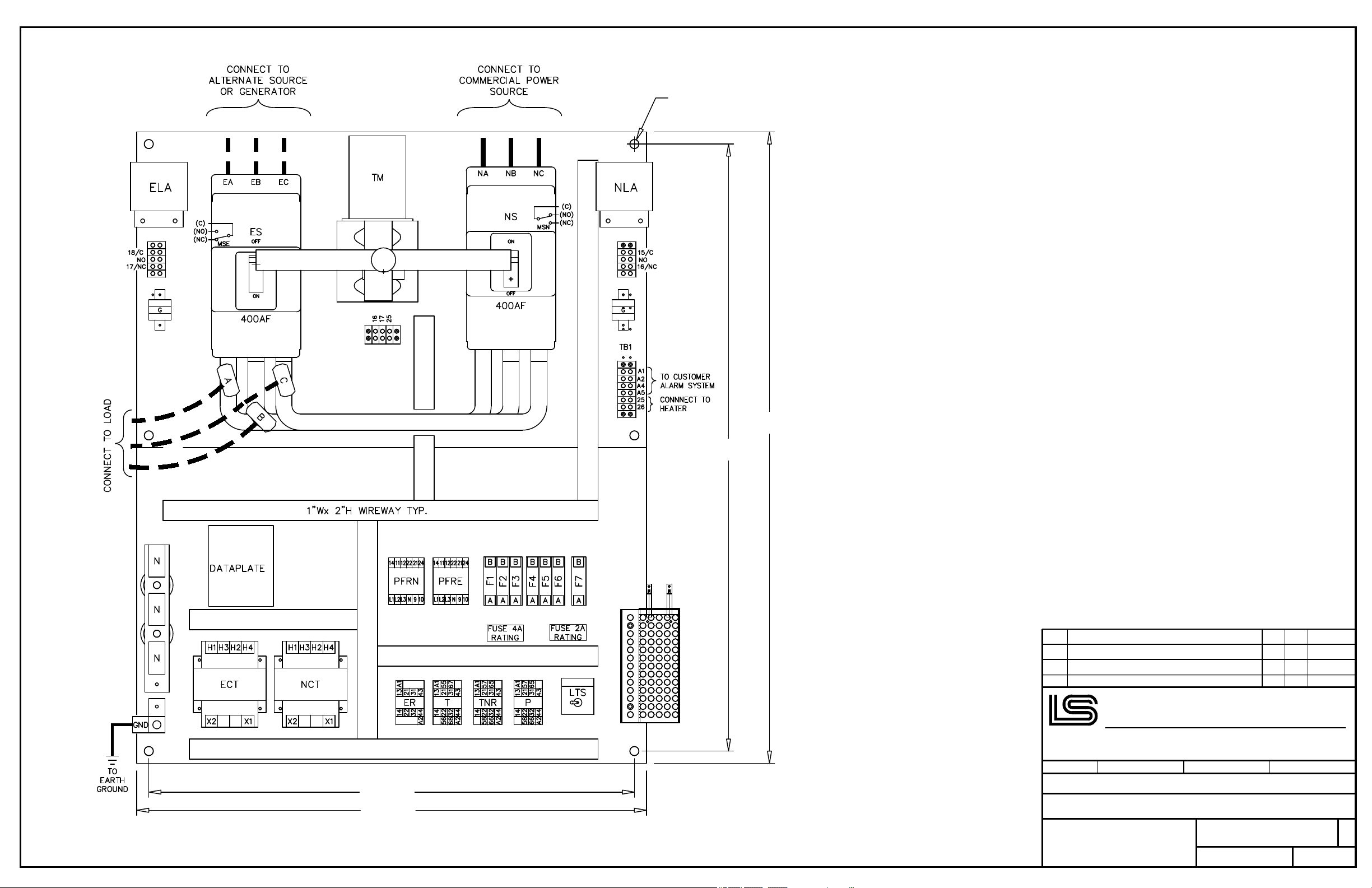

1. CONSTRUCTION .............................................................................................................................................................................. 11

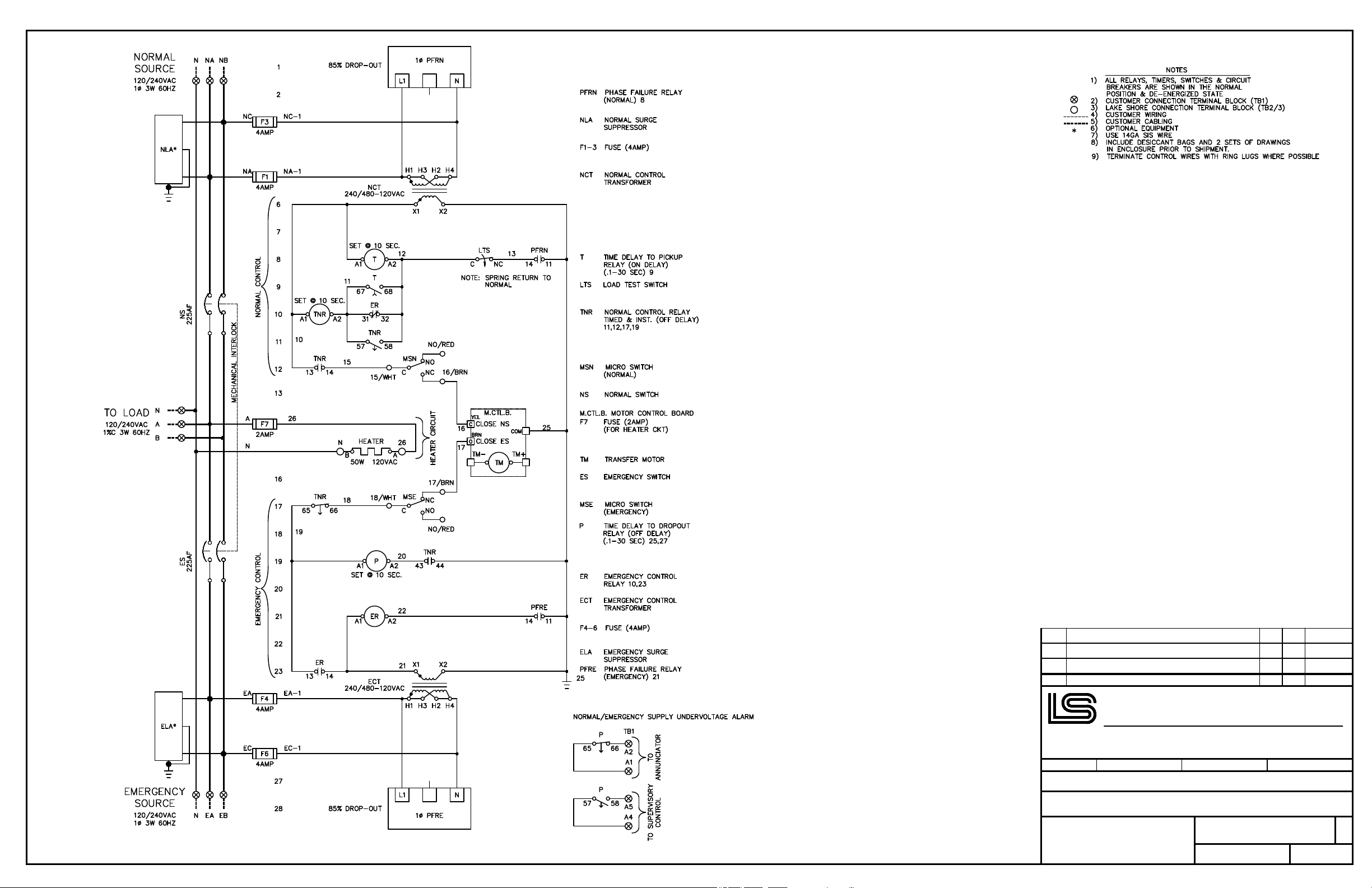

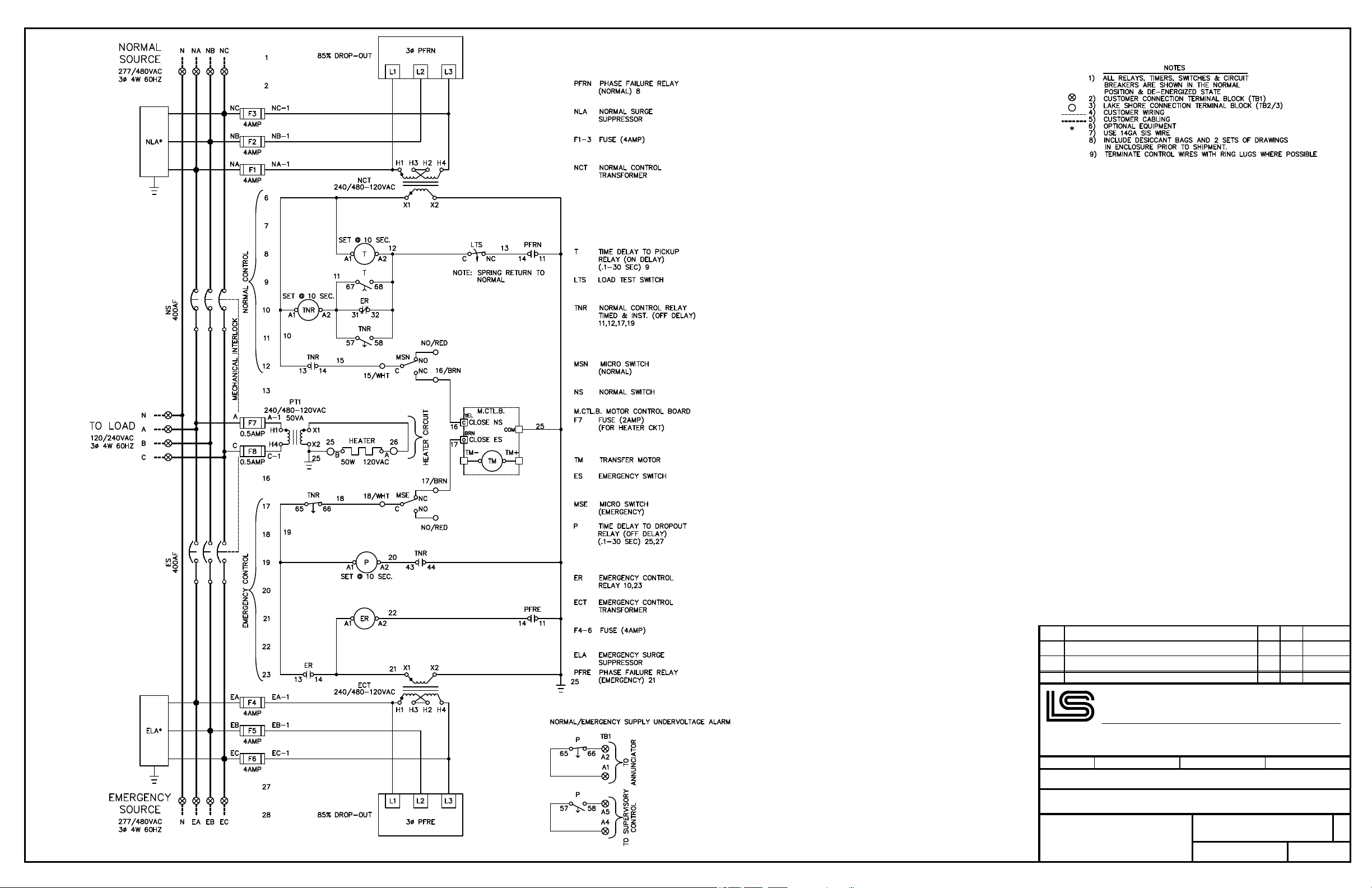

2. DESCRIPTION OF OPERATION.................................................................................................................................................. 11

3. INSTALLATION ................................................................................................................................................................................ 12

3.1. MOUNTING AND CONNECTING ........................................................................................................................................... 12

3.2. PLACING THE TRANSFER SWITCH IN OPERATION .................................................................................................... 12

4. OPERATING MECHANISM ........................................................................................................................................................... 14

4.1. GENERAL INFORMATION....................................................................................................................................................... 14

4.2. OPERATION .................................................................................................................................................................................. 14

4.3. REQUIRED MAINTENANCE ................................................................................................................................................... 14

4.4. MOTOR ASSEMBLY ................................................................................................................................................................... 14

5. MOLDED CASE SWITCHES .......................................................................................................................................................... 16

5.1. GENERAL INFORMATION....................................................................................................................................................... 16

5.2. INSPECTION AND MAINTENANCE ..................................................................................................................................... 16

6. TIMING RELAYS .............................................................................................................................................................................. 17

7. VOLTAGE RELAYS .......................................................................................................................................................................... 17

7.1. VOLTAGE SENSING – CLOSE DIFFERENTIAL ................................................................................................................ 17

8. TROUBLESHOOTING GUIDE ...................................................................................................................................................... 19

9. APPENDIXES ..................................................................................................................................................................................... 22

9.1. APPENDIX A ................................................................................................................................................................................. 22

9.2. APPENDIX B ................................................................................................................................................................................. 23

9.3. APPENDIX C ................................................................................................................................................................................. 24

9.4. CLOSE DIFFERENTIAL UNDERVOLTAGE PROTECTION ........................................................................................... 26

NOTE

Engineering changes may have been made after publication date. Any departure from this manual

should be checked with Lake Shore Electric Corporation.

Lake Shore Electric Corporation reserves the right to change specifications without prior notice.