Page 3ALTO Access Products |Lakeside Industries Ltd

Inspection Care & Maintenance

Alto Access equipment is designed and manufactured to the highest standards in the industry and is stronger,

more robust and safer than any comparable competitor product. Properly cared for, it will give a long and

productive service life.

All Alto equipment should be subjected to the care and maintenance regime specied in the assembly guide

supplied with your Room Scaold.

Never use any equipment which is damaged, has parts missing or is improperly assembled.

Safety

· A risk assessment and method statement must be prepared sufficient to ensure the safe assembly,

use and dismantling of a Room Scaffold and the elimination or minimisation of all consequent risks.

· Check that all of the necessary components and equipment for the particular Room Scaffold

configuration to be built are on site, undamaged & functioning correctly. Damaged/incorrect

components must not be used.

· Check that the surface on which the Room Scaffold is to be located is capable of supporting the Room

Scaffold and its payload.

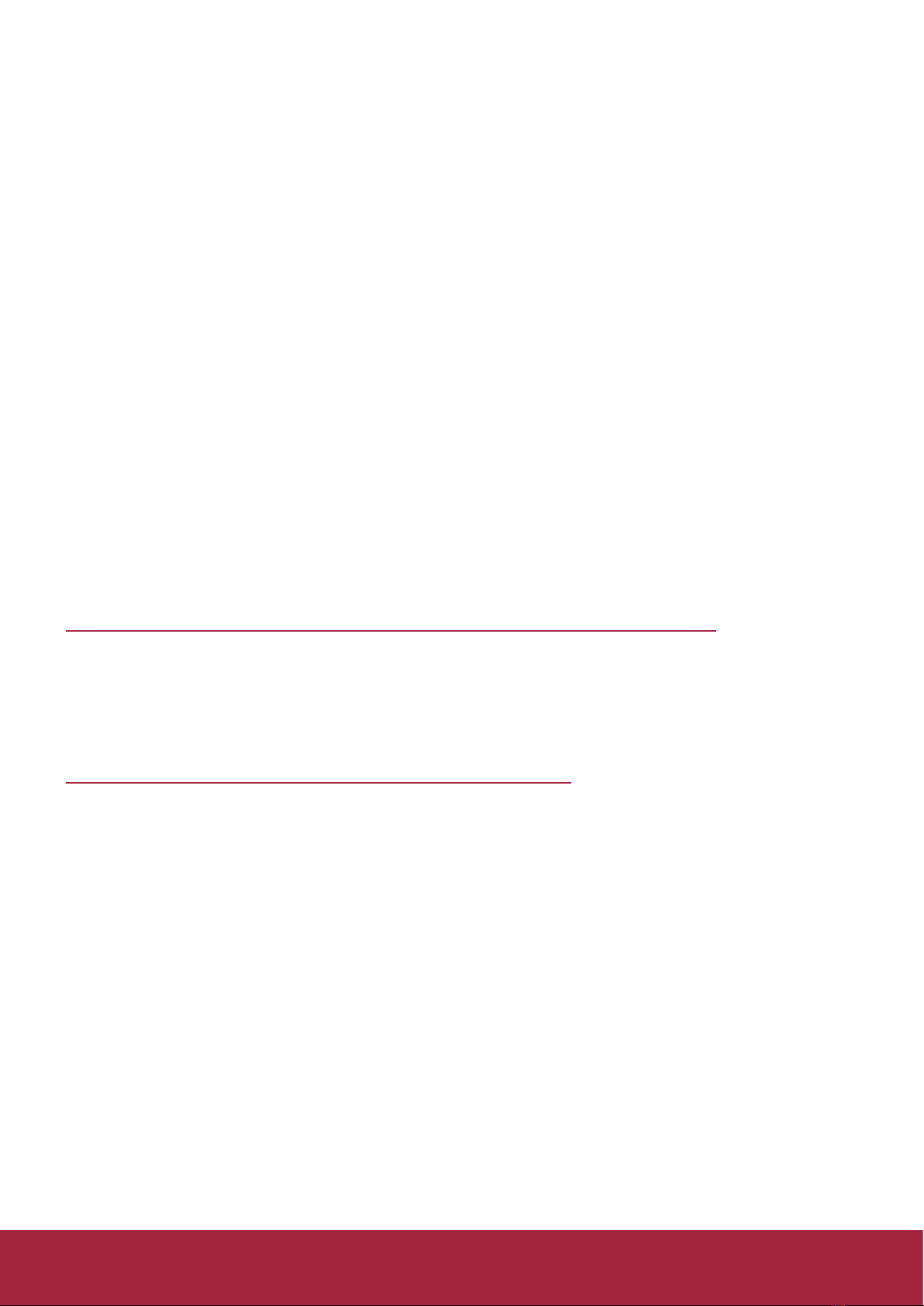

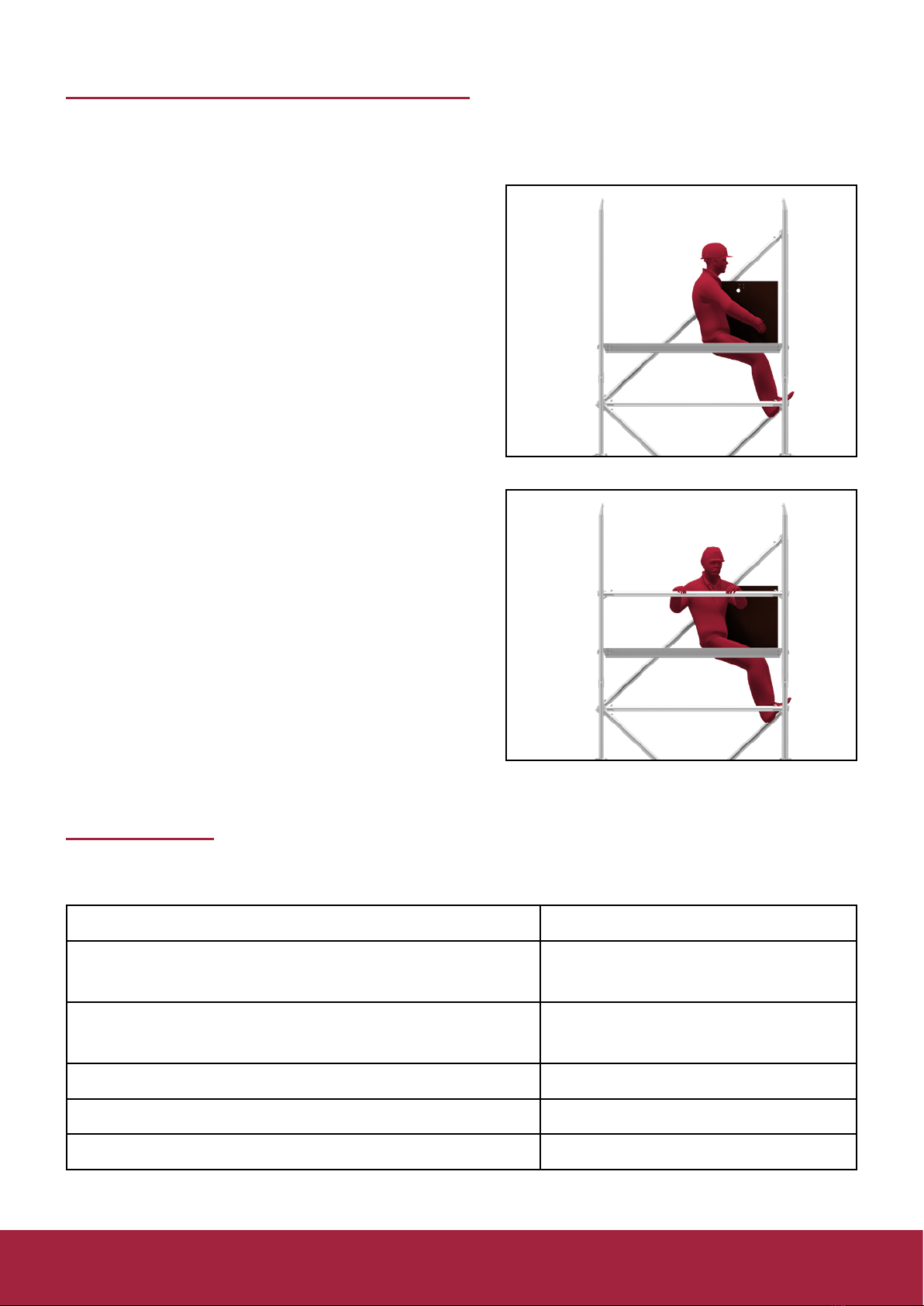

· Room Scaffolds must always be climbed from the inside.

· Do not ride on or attempt to move a loaded Room Scaffold.

· Never remove components from a Room Scaffold whilst it is in use.

· Do not lean ladders, steps or other objects against the Room Scaffold.

· The Room Scaffold many not be used as a means of access to another place.

· Do not overreach.

· Always wear appropriate personal protective equipment and work-wear including foot wear with a

flat firm sole and a good grip.

· The Room Scaffold is only to be used on level ground. Do not adjust the height using adjustable legs.

· Always take safety measures when working close to doorways, openings and other traffic paths, to

prevent accidental collisions. Never block emergency exits, fire-paths or other escape routes.

· Always comply with the Work at Height Regulations 2005 when erecting, dismantling & using the

Room Scaffold.

· Never use this ALTO Room Scaffold until you are sure you are competent in its use and physically able

to safely enter, exit and work from the platform.

· Never use the ALTO Room Scaffold if you are feeling unwell or you have taken any alcohol, medication