BETA MONTECARLO

SHOP MANUAL FOREWORD

HOW TO CONSULT THIS MANUAL

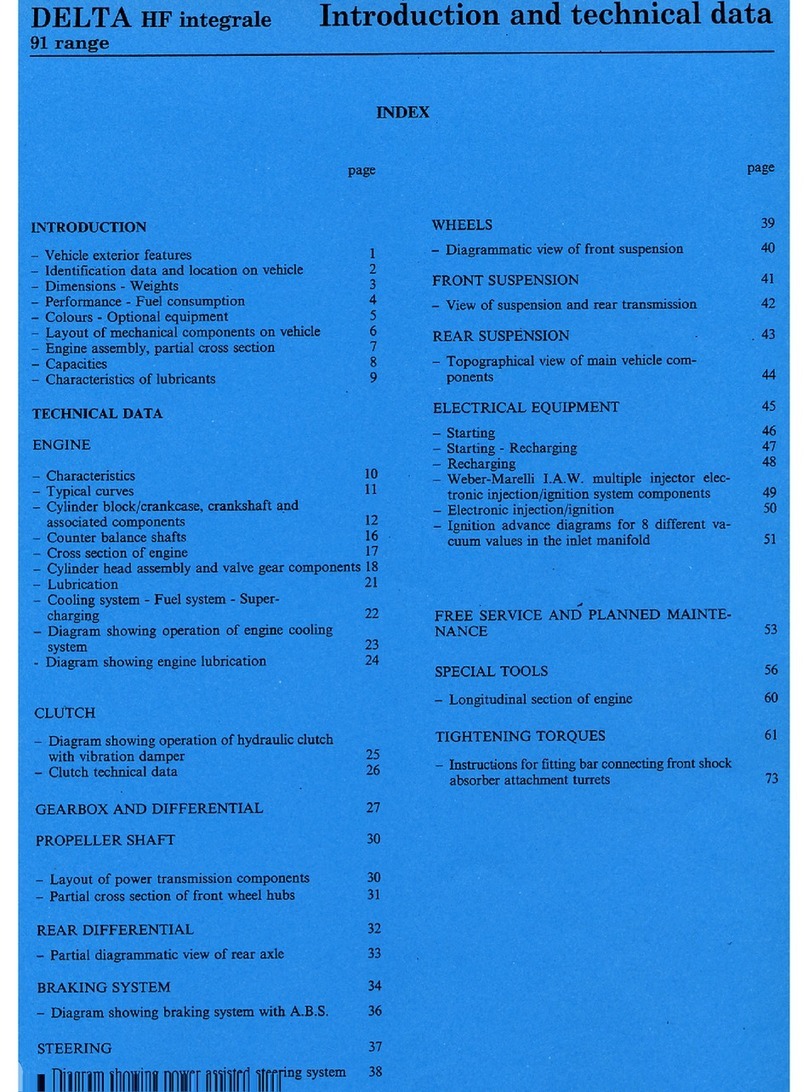

The manual is divided into 17 sections, each dealing with a separate assembly or group of opera-

tions (e.g. 01 Engine, 02 Clutch, 03 Gearbox, 09 Brakes etc.).

At the beginning of these sections, the list of contents may followed by a part listing the essential

features of the assembly.

This initial part of the section may also include descriptions of the workings of parts forming part

of the assembly.

Each section is generally subdivided into four chapters:

CHAPTER 1 -Troubleshooting

This looks at the faults that might crop up and their likely causes, and then shows how to rec-

tify them.

The faults indicated in this chapter are listed without numbering.

NB For the sake of cQmpletion, all faults are listed, even those which are highly unlikely to

occur .

CHAPTER 2 -Repairs

This chapter describes tuning operations and adjustments and those removal-refitting jobs which

can be done on the car in the workshop.

CHAPTER 3 -General overhaul of assembly

This deals with overhauls of complete assemblies which have to be done Ol:lthe bench (e.g. Engine,

gearbox, transmission etc. overhaul).

Of course, not all sections will have this Chapter; assembly 14, the electric system, for example

cannot be overhauled at the bench.

CHAPTER 4 -Bench overhaulsubassemblies

This chapter details the operations at the bench for overhauling subassemblies that may be remo-

ved directly from the car (Chapter 2) or from the full assembly, at the work bench, during general

overhaul operations (Chapter 3).

(E.g. Cylinder head, oil pump etc. forming part of assembly 01 Engine).

All the operations outlined up to now form that part of each assembly known as the "Basic

Model".

These operations apply to all models of the car unless specific exceptions are given in the contents

of each section. In cases where operations are so different that they require special attention, the

heading of the contents of each section, "BASIC MODEL II -"Operations relevant to all models" is

followed by the wording "Variants -Operations relevant only for mode1s " followed by the variant

number.

The pages in each chapter are numbered progressively and assembly section and chapter are also

indicated (e.g. page 01 2/24 standsforthe 24th page of Chapter 2 of Section 01 Engine).

All operations contained in Chapters 2, 3 and 4 of each section are identified by numbers of

seven digits arranged in ascending order, from the first operation described in Section 01 Engine, to the

last operation of Section 17 Maintenance.

The number that identifies each operation (preceded by paragraph symbol..) consists, as we have

said, of seven digits:

The first two digits (011 02, 03, 16,17) indicate the assembly section to which the operation

belongs.

The third digit (2, 3, 4) identifies the chapter, namely that part of the workshop in which the

operation is carried out.