Page 2

Contents

Ordering Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Technical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

General Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Designated Use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Safety Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Wall Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

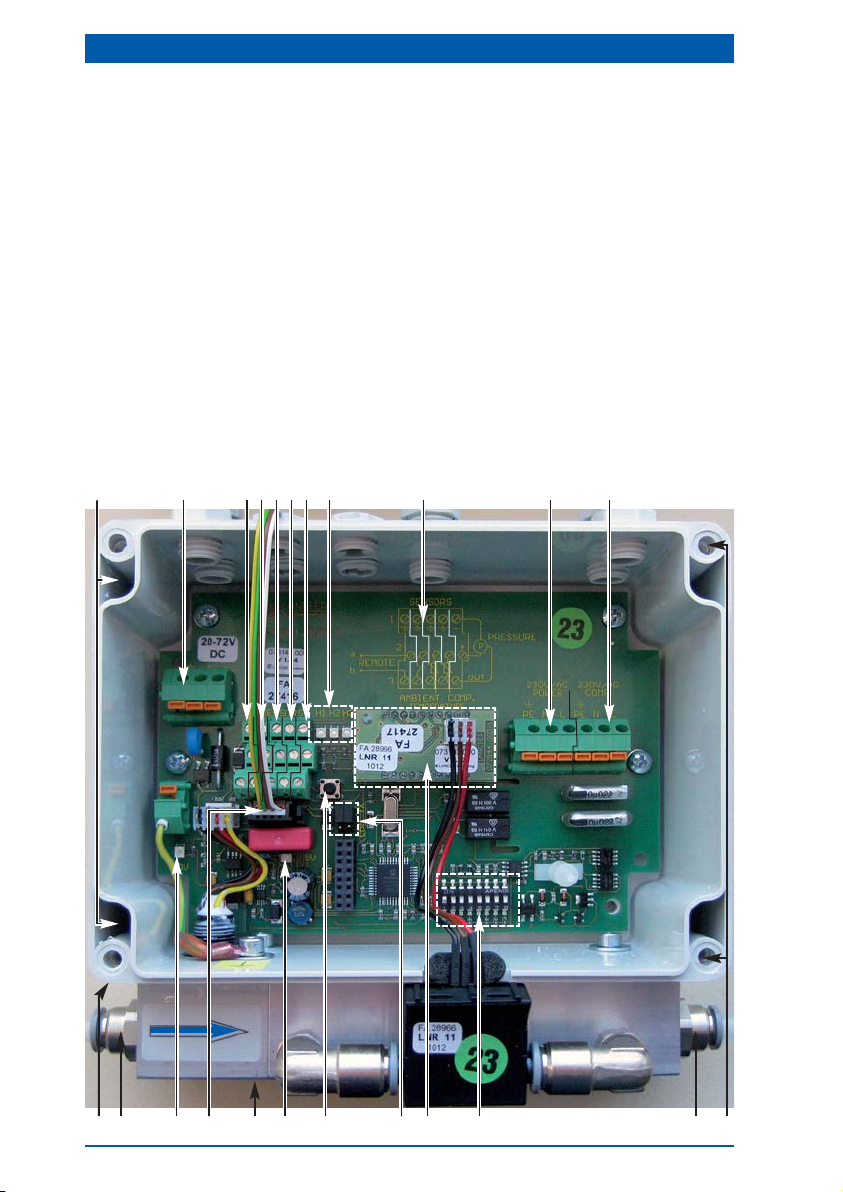

Hooking up the Device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

General Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Supply Voltage and Measurement Wires . . . . . . . . . . . . . . . . . . . . . . . . .12

Supply Voltage: 20-72 V DC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Sensor cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

2-Wire Bus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Humidity Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Outlet Air Temperature Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Optional external Sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

External contact sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

External –20 to 80 °C temperature sensor (ambient temperature) . . . . .13

External -50 to 180 °C temperature sensor (compressor temperature) .13

External 0 to 10 bar pressure sensor . . . . . . . . . . . . . . . . . . . . . . . . . . .13

System Voltage and Compressor Runtime . . . . . . . . . . . . . . . . . . . . . . . .13

System Voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

Compressor Runtime . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

Pressure Hose Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

The Lancier Tx Bus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

Encoding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

Encoding Table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Commissioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

Operation of ACS with display and control panel . . . . . . . . . . . . . . . . . . . . .18

Operate the ACS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

Menu Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

Read out ACS Values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

Read out ACS Info . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

Display Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

Read out Display Info . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21