8

2M-W1091, Commerical & Marine Electric Range Top

2M-W1091, Commerical & Marine Electric Range Top

INITIAL START-UP continued

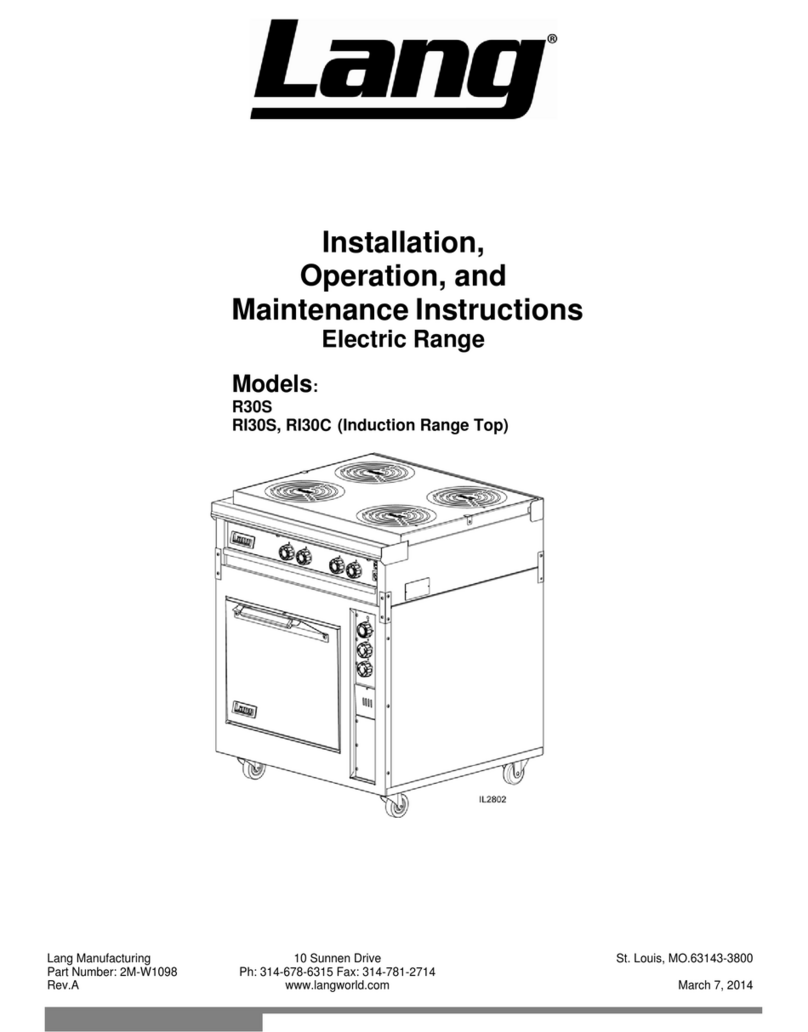

Induction Burners

Induction requires cookware that is induction efcient or that is made for use on an induction surface.

Generally speaking if a magnet attracts and strongly adherse to the pan bottom it will generally work on

an induction surface. This is a requirment for proper use. DO NOT USE WITH EMPTY PANS.

To operate unit turn the knob clockwise and a small digital number will appear next to the hotplate to

be cooked on. The higher the number the faster the heat up. Heating will begin when the pan surface

comes in contact with the induction surface and will cease when the pan is removed. Note: surface will

remain hot for a certain period of time after the pan is removed.

Induction module, controlled by variable heat control. Great for rapid heat-up, it will generally boil water,

heat sauces or soups in about half the time of a French Plate. Use caution placing items on the glass

cook surface, always wipe down glass with mild soap and water to keep the unit clean.

Griddles

To “dry out” the griddle, set the thermostat to 250°F and turn on the power switch. Allow the unit to cycle

at least 15 minutes at this heat level. Reset the thermostat to 350°F allow the same time. Reset the

thermostat to 450°F and allow the unit to maintain the temperature for a minimum of 4 hours. More time

may be required if the unit has to operate in a moist environment.

If the unit is out of use for three or more days, a one-hour preheat schedule should be used, especially

when exposed to high humidity and/or cool temperatures.

Duringtherstfewhoursofoperationyoumaynoticea small amount of

smoke coming off the range, and a faint odor from the smoke. This is normal

foranewrangeandwilldisappearaftertherstfewhoursofuse.

ALWAYS KEEP THEAREANEAR THEAPPLIANCE FREE FROM COMBUSTIBLE

MATERIALS.

KEEP FLOOR IN FRONT OF EQUIPMENT CLEANAND DRY. IF SPILLS OCCUR,

CLEAN IMMEDIATELY, TO AVOID THE DANGER OF SLIPS OR FALLS.

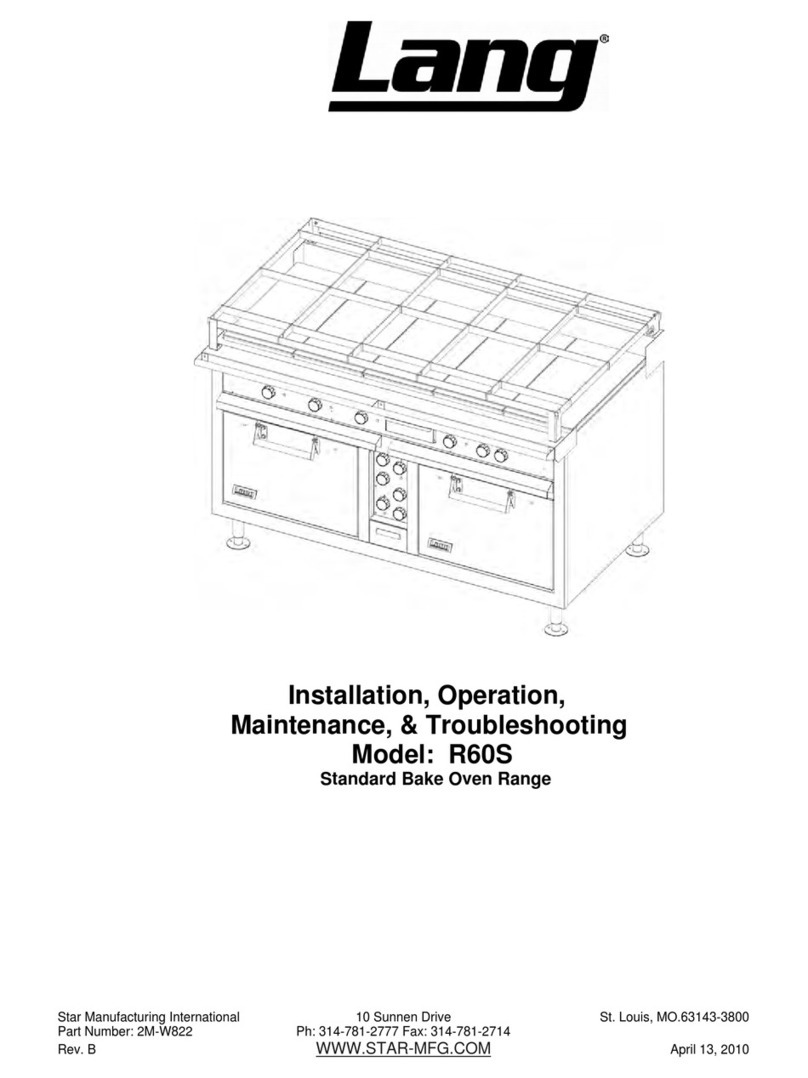

RANGE TOP

Consists of the various top arrangements, depending on specic model purchased:

12” x 24” hot plate controlled by high temperature thermostats. Temperature ranges from 0°F-850°F.

Recommended: Stock pots and heavy kettle work.

Round French Plates, controlled by indicating type 6-heat switch. Temperature ranges from 0°F-750°F.

Recommended: Light duty sauce pans and small stockpots. Not Recommended: Heavy stock pots, or

heavy urns, or kettles.

36” x 24” or 24” x 24” grill plates, controlled by thermostats. Temperature ranges from 0°F-450°F.

Recommended: All heavy and light frying. Set the thermostat dial at the desired temperature. The red

pilot light will be on until the desired temperature is reached. The pilot light indicates that the plate is

heating.

CAUTION

NOTICE