p/n 2M-W2029 OpM LVC- Ventless Universal Hood

4

PRECAUTIONS AND GENERAL INFORMATION

This ventilator hood is part of an engineered system and is intended for

use in commercial establishments only.

This ventilator is intended

for commercial establishments for use

in the preparation food for human consumption. No other use is

recommended or authorized by the manufacturer or its agents.

Operators of this appliance must be familiar with the appliance use,

limitations and associated restrictions. Operating instructions must be

read and understood by all persons using or installing this appliance.

This ventilator hood system is designed to reduce odor emissions,

but will not completely eliminate all cooking odors. Air exchange

rates at the installation site must comply with the requirements of the

local jurisdictional authority. To ensure that odors do not accumulate,

recommendedminimumairexchangeis200cfmperlinearfootofhood

into and out of the site.

This unit is intended for use with light- and medium duty electric

cooking appliances only. Cooking appliances placed under this

ventilator must comply with the restrictions set forth in the Installation

section of this manual.

Do not connect or energize this appliance until all installation

instructions are read and understood. Property damage or bodily

injury may result if these instructions are not followed. Disconnect this

appliance from electrical power before performing any maintenance or

servicing.

Cleanliness of this appliance is essential to good sanitation. Read and

follow all included cleaning instructions and schedules to ensure the

safety of the food product.

This appliance is not jet steam approved. Do not direct water jet or

steam jet at this appliance, or at any control panel or wiring.

Do not splash or pour water on, in or over any controls, control panel or

wiring.Donotattempttowashlterpacks.Waterwillcausetheir

immediate failure and disable the ventilator.

Exposed surfaces of this appliance can be hot to the touch and may

cause burns.

Avoidstoringammableorcombustiblematerialsin,onornearthe

ventilator or associated cooking appliance.

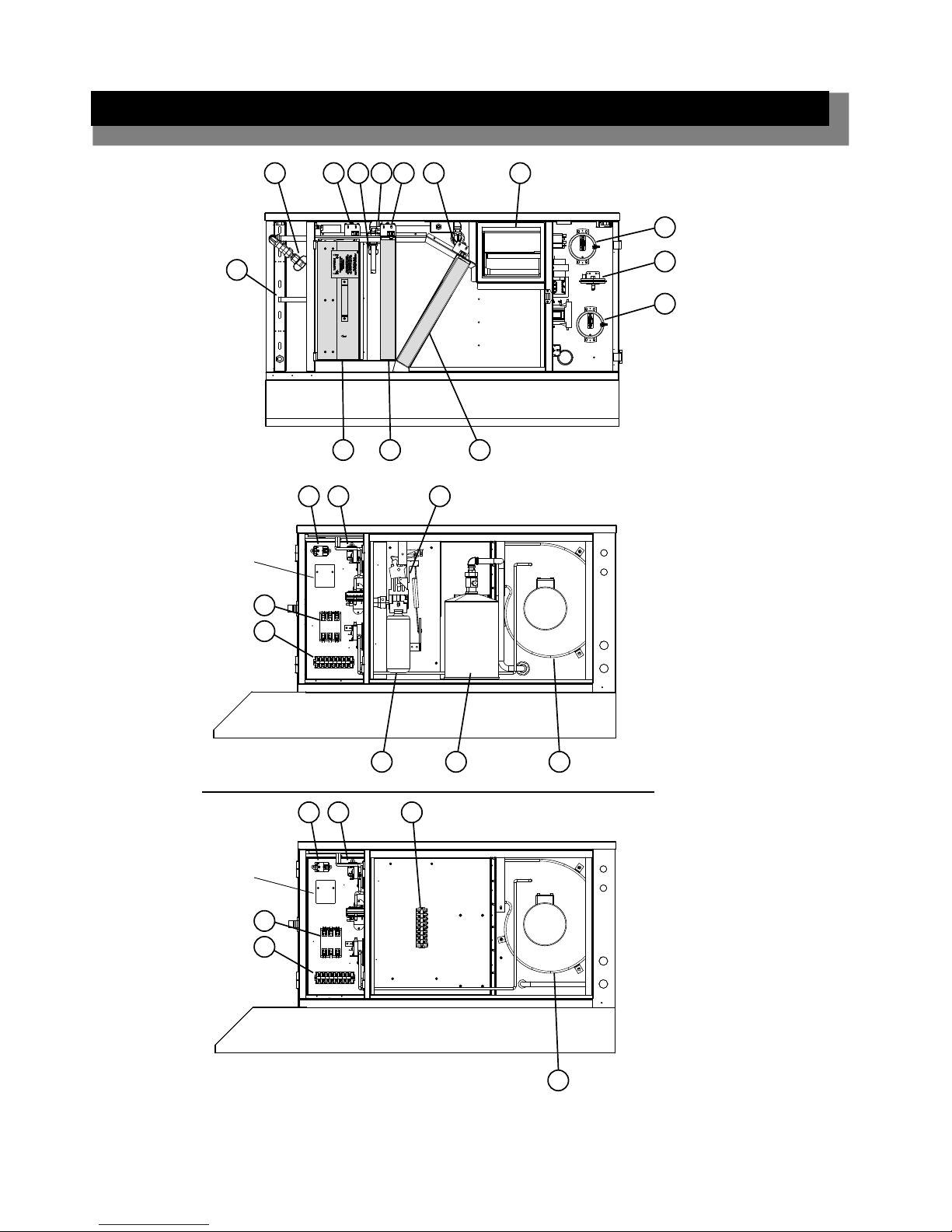

The technical content of this manual, including any wiring diagrams,

schematics,partsbreakdownillustrationsand/oradjustment

procedures,isintendedforusebyqualiedtechnicalpersonnel.

Any procedure which requires the use of tools must be performed by a

qualiedtechnician.

All supplied instructions, diagrams, schematics, parts breakdown

illustrations, notices and labels must remain with the appliance if the

unit is sold or moved to another location.

This appliance is made in the USA. Unless otherwise noted, this

appliance has American sizes on all hardware.

DANGER:

SUFFOCATION HAZARD

Do not attempt to use this

ventilatorwithgas-redunits.

This ventilator will not remove

products of combustion.

Unvented exhaust gasses

can be deadly.

WARNING:

SHOCK HAZARD

All servicing requiring

access to non-insulated

electrical components must

be performed by a factory

authorized technician.

DO NOT open any access

panel which requires the use

of tools. Failure to follow this

warning can result in severe

electrical shock.

IMPORTANT:

The ventilator is disabled

whentheltersareclogged

tothepointofinsufcient

airowforproperoperation.

Also, power to the cooking

appliances is interrupted if

anyltersorservicepanel

are removed.

It is the responsibility of

the store management to

maintainsufcientspares

oflterpackstoavoid

prolonged shutdown due

toadirtyorcloggedlter

pack. Filter packs cannot be

cleaned.

Lang Manufacturing

assumes no liability for loss

ofbusinessduetoalter

related shutdown. Spare

lterscanbepurchasedfrom

any authorized Lang servicer

or calling (314) 678-6315.