Lares 330E – JC (Jacobs Chuck)

Repair Procedure

1. Lares 330E –JC Handpiece

2. Lares Disassembly Punch (00024L1)

3. Lares Back Cap Wrench

4. Small Flathead Screwdriver

5. Small Channel Lock Pliers

6. Wire Reamer

7. Push Pin

The Lares 330E – JC is one of the lightest high speed handpieces made. It also has one of the

smallest heads, making it a favorite for pediatric dentists. Unfortunately, this handpiece often

fails prematurely, especially with regards to the front bearing, making it a source of frustration

for both doctors and repair techs, alike. This handpiece can be converted to a pushbutton style

handpiece by simply following the repair procedure for the Lares 557 Turbo – PB (following this

section). The pushbutton back cap does make the head a bit larger, however.

STEP 1 Try to determine the problem before opening the handpiece. Insert a high speed

bur (see Step 2 below), checking that it inserts smoothly and tightens securely.

Twist the bur manually to feel how smoothly it turns. Attach it to your air hose

and run the handpiece (if you can). Check that air pressure is at 38 p.s.i.. Listen

for the appropriate pitch at full speed and for a smooth rundown. Check the water

spray – it should be a fine mist. Attempt to cut a shell to test the torque.

Disassemble the handpiece following the instructions below.

DISASSEMBLY

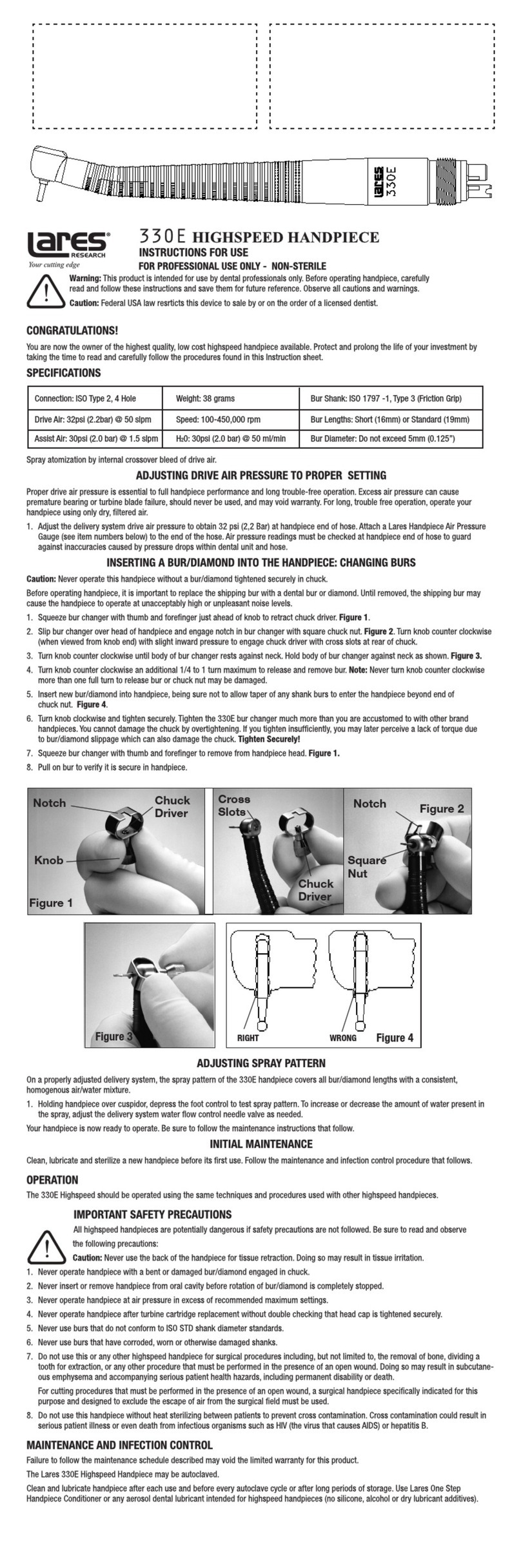

STEP 2

Most repair techs will not have the original Lares bur tool and therefore, must

improvise, as seen in the photo to the left. Grasp the chuck nut with a pair of

small channel lock pliers. Then, using a small flathead screwdriver, twist in a

counterclockwise direction one or two turns – just enough to loosen the bur and

not remove the nut. To insert a bur, simply reverse the process.

STEP 3

Remove the back cap using the Lares back cap wrench. Unfortunately, these

wrenches are only available to dentists who use this handpiece. Luckily, they

usually have quite a few of them and will share one with you, if you ask nicely.