4

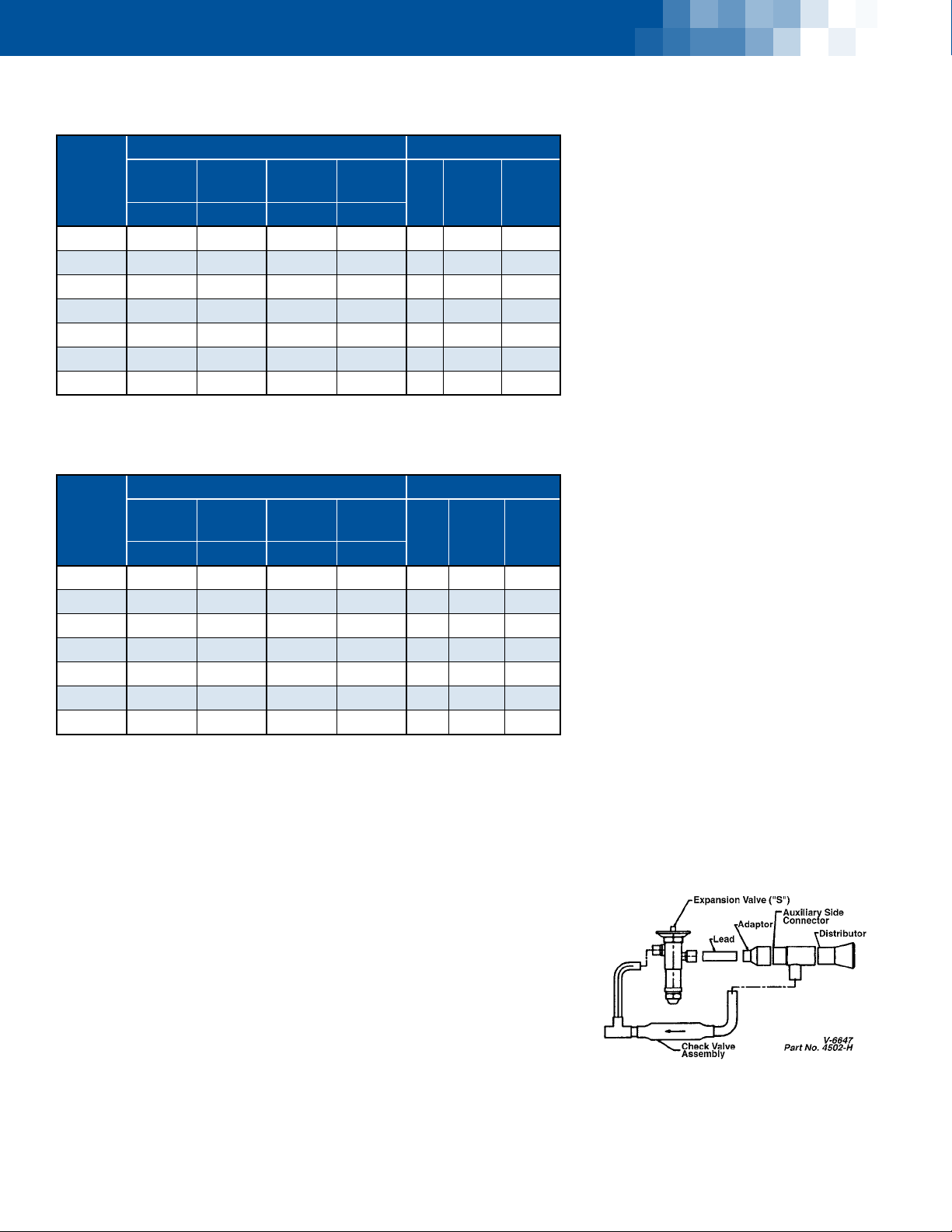

Model LWA Air Defrost | 60 Hz

Model

Capacity Fan Data

10°F TD

25°F SST

6°C TD

-4°C SST

15°F TD

25°F SST

8°C TD

-4°C SST

50-55°F DB

55% RH 20°F TD No. CFM m3h

Total Sensible

BTUH Watts BTUH Watts BTUH Watts BTUH Watts

LWA050 5,000 1,460 7,500 2,200 10,000 2,930 8,500 2,490 1 725 1,233

LWA075 7,500 2,200 11,250 3,300 15,000 4,390 12,750 3,730 1 730 1,241

LWA100 10,000 2,930 15,000 4,390 20,000 5,860 17,000 4,980 2 1,450 2,465

LWA130 13,000 3,810 19,500 5,710 26,000 7,620 22,100 6,470 2 1,470 2,499

LWA155 15,500 4,540 23,250 6,810 31,000 9,080 26,350 7,720 2 1,460 2,482

LWA180 18,000 5,270 27,000 7,910 36,000 10,540 30,600 8,960 3 2,130 3,621

LWA210 21,000 6,150 31,500 9,230 42,000 12,300 35,700 10,460 4 2,840 4,828

LWA270 27,000 7,910 40,500 11,860 54,000 15,820 45,900 13,440 4 2,800 4,760

LWA340 34,000 9,960 51,000 14,940 68,000 19,920 57,800 16,930 5 3,500 5,950

Performance Data

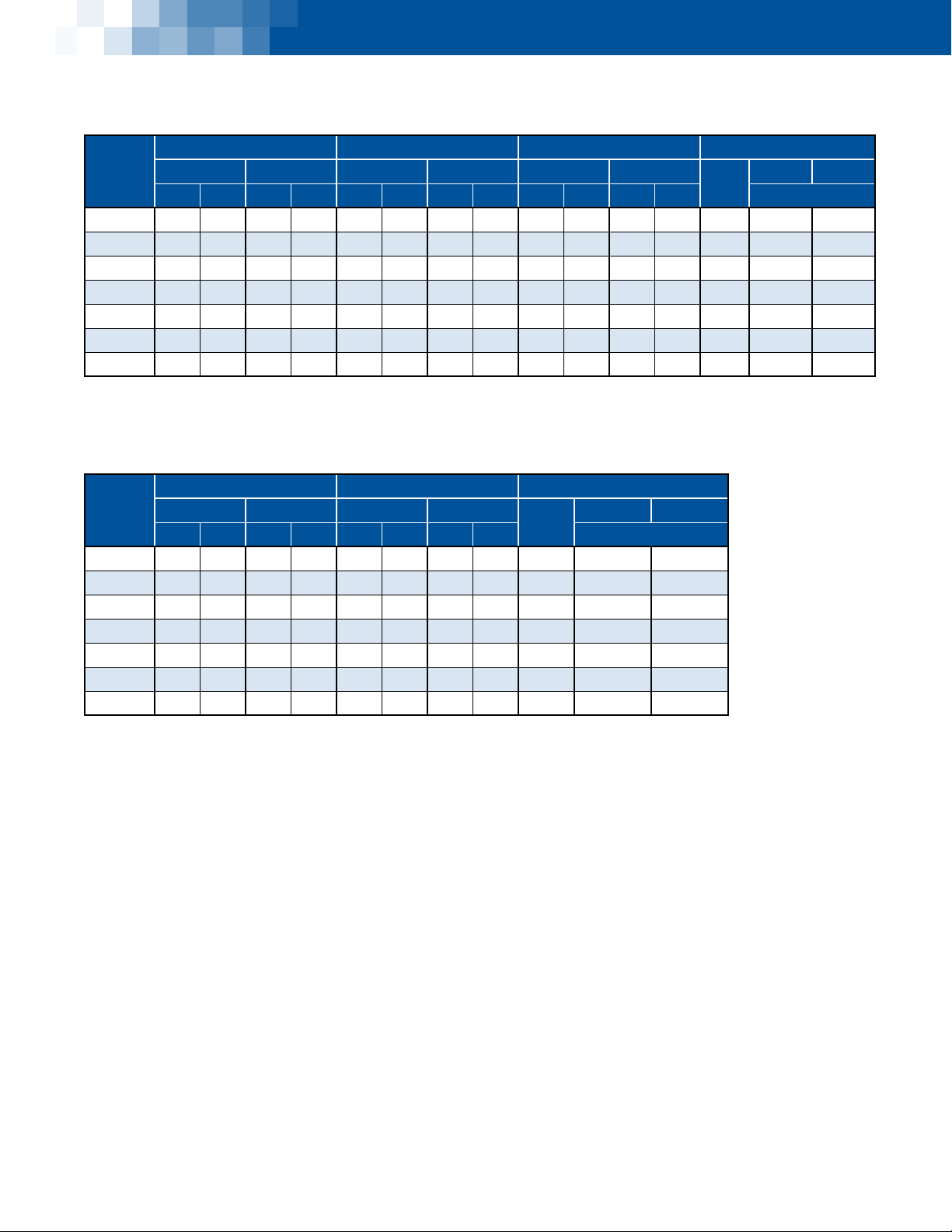

Model LWA Air Defrost | 50 Hz †

Model

Capacity Fan Data

10°F TD

25°F SST

6°C TD

-4°C SST

15°F TD

25°F SST

8°C TD

-4°C SST

50-55°F DB

55% RH 20°F TD No. CFM m3h

Total Sensible

BTUH Watts BTUH Watts BTUH Watts BTUH Watts

LWA050 4,800 1,410 7,100 2,080 9,500 2,780 8,100 2,370 1 660 1,122

LWA075 7,100 2,080 10,700 3,130 14,300 4,190 12,100 3,540 1 660 1,122

LWA100 9,500 2,780 14,300 4,190 19,000 5,570 16,200 4,740 2 1,310 2,227

LWA130 12,400 3,630 18,500 5,420 24,700 7,230 21,000 6,150 2 1,330 2,261

LWA155 14,700 4,310 22,100 6,470 29,500 8,640 25,000 7,320 2 1,320 2,244

LWA180 17,100 5,010 25,700 7,530 34,200 10,020 29,100 8,520 3 1,920 3,264

LWA210 20,000 5,860 29,900 8,760 39,900 11,690 33,900 9,930 4 2,560 4,352

LWA270 25,700 7,530 38,500 11,280 51,300 15,030 43,600 12,770 4 2,530 4,301

LWA340 32,300 9,460 48,500 14,210 64,600 18,920 54,900 16,080 5 3,160 5,372

†For EC motors, use 60 Hz capacity and airflow values (Units with EC motors operating at 50 Hz will not see a reduction in

performance due to the electronic control of the motor)