PAGE 10

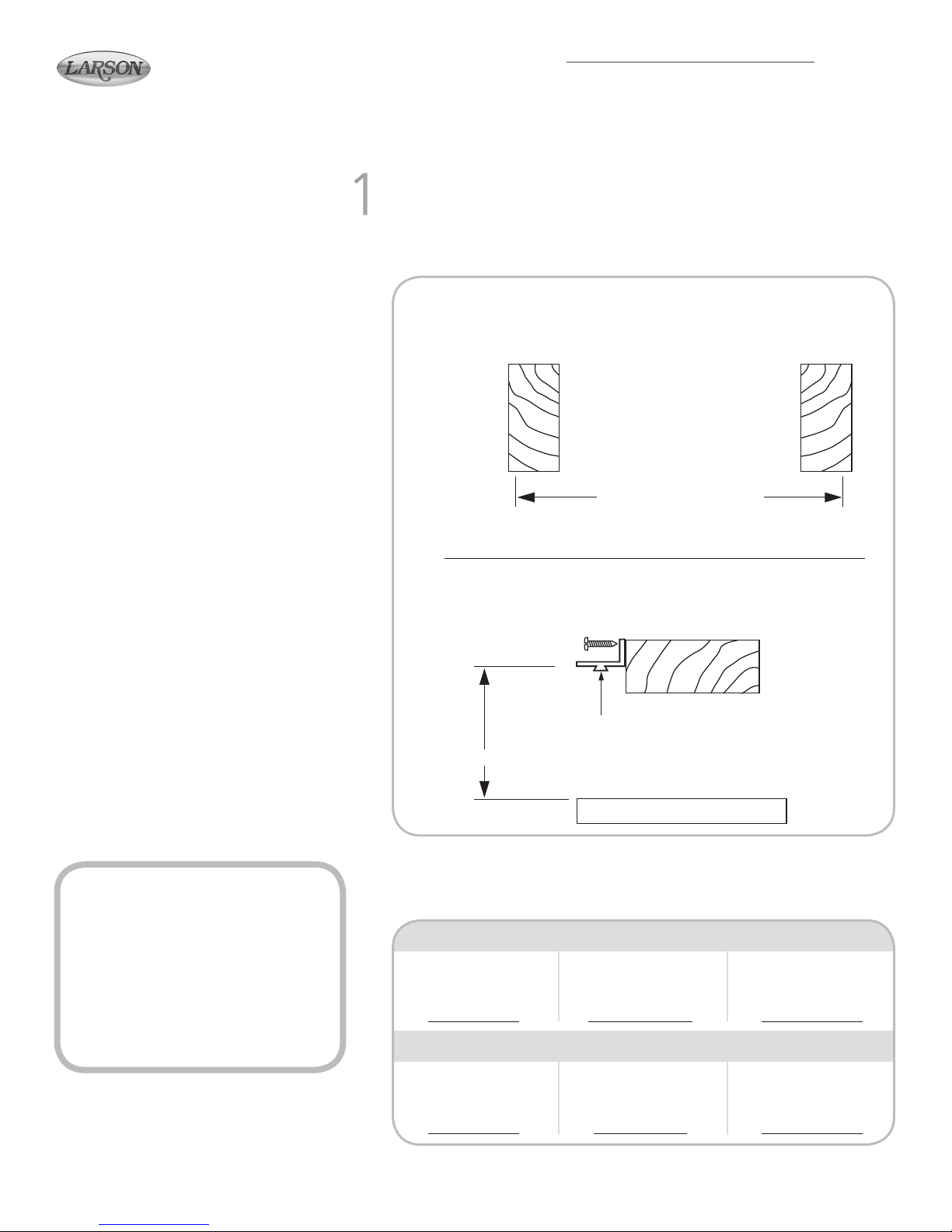

Retractable screens should always be installed square, plumb and level.

THE SCREEN FABRIC GETS BLOWN OUT OF THE SIDE TRACKS

An Anti-Wind Brush Pile is located inside the B-Inside Rails. This Anti-Wind Pile is designed so that

the stiff bristles of the Brush Pile will engage inside the holes of the screen fabric as wind blows/

pushes on the fabric. Check that the aluminum walls of the B-Inside Rails have not been bent

outward during customer installation since this will prevent proper engagement. If needed take your

thumb and forefinger and gently run them along the length of the B-Inside Rails altering these back

into a straight 90-degree position. This will reposition the Anti-Wind Pile so that it can perform as

intended.

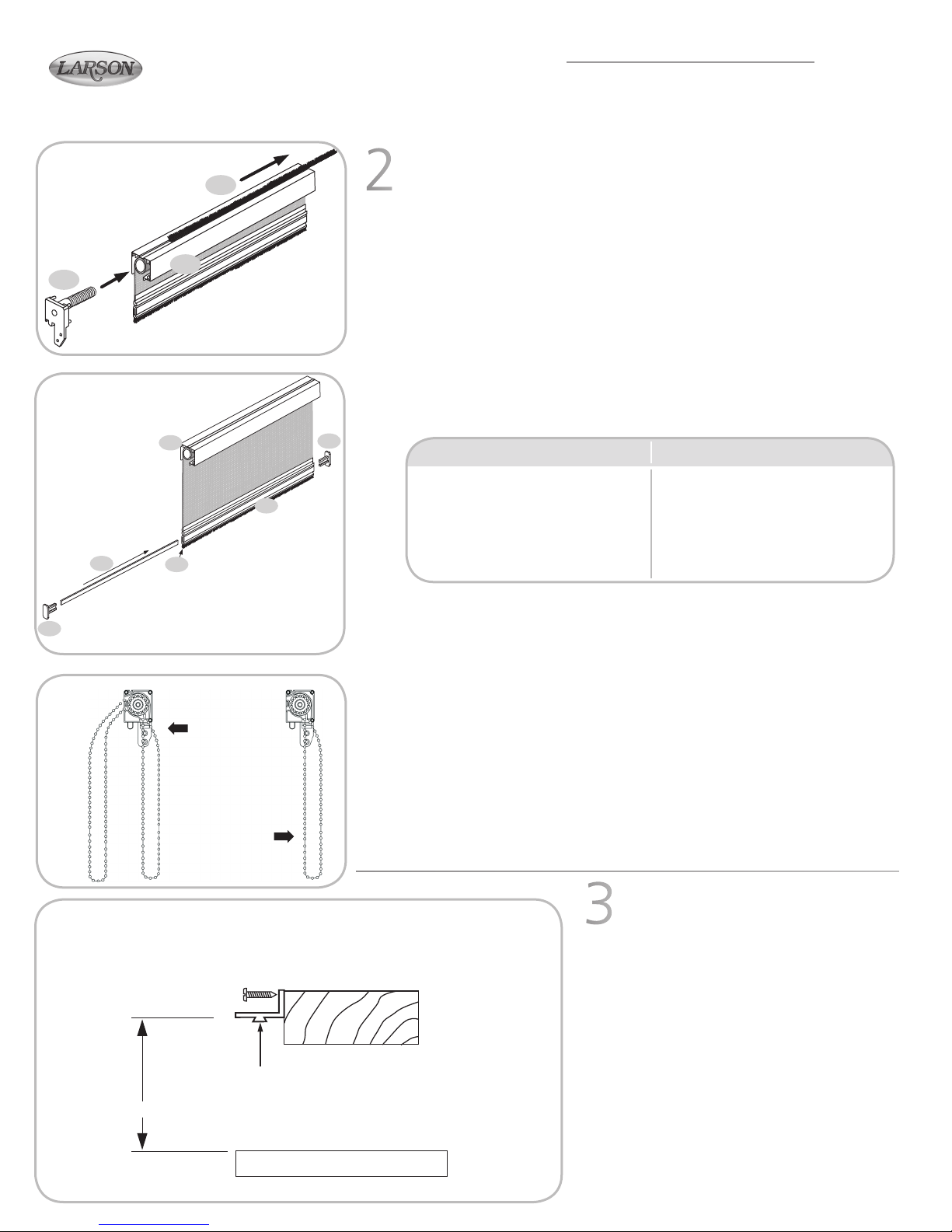

Be sure that the L-Pull Bar Lock engages the D-Pull Bar as shown in image [Fig 4C]. Using the height adjustment wheel on the

L-Pull Bar Lock, adjust the height to the appropriate level so that it easily engages the L-Pull Bar. When correctly adjusted the

latching and unlatching should be smooth and easy and the screen will stay latched until manually released.

Check that the Anti-Wind Brush Pile has not been deformed or damaged and that it is still pointing in a 60 degree angle within

the B-Inside Rails.

Add an additional O-Weight Bar (or other ballast material) inside the D-Pull Bar.

Windy conditions may affect the performance of a retractable screen. Retract the screen in windy circumstances, during

inclement weather, when not needed to support immediate ventilation or during prolong periods when not used.

THE SCREEN IS DIFFICULT TO PULL DOWN OR UP

Check that the screen has been installed in a square and plumb opening. Adjust the opening as needed.

An Anti-Window Brush Pile is located just inside the B-Inside Rails. Gently run your finger or another soft object down each

side of the screen fabric in order to release the engagement of the Anti-Wind Brush Pile within the small openings in the Screen

Fabric. Now retract the screen.

Check and correct any interference (e.g. screws or debris) inside the B-Inside Rails.

Check that the D-Pull Bar glides smoothly. Slightly trim the aluminum D-PULL BAR if needed.

Check to see if the J-Weatherstrip is catching or binding in the B-Inside Rails

Remove the plastic Cassette End Cap with Chain from the A-Screen Cassette Assembly and verify that the allen screw is not

fastened so tightly that it is restricting the operation.

THE SCREEN DOES NOT RETRACT EVENLY

Check that the screen has been installed in a square and plumb opening. Correct the opening as needed.

Pull the screen all the way down to the bottom of the opening and then retract the screen. This will often help the screen fabric

to realign.

Pull the screen all the way down to the bottom of the opening. Look to see if there are creases in the fabric or other signs

indicating that the screen fabric may have rolled over itself inside the A-Screen Cassette Assembly. If needed remove the

A-Screen Cassette Assembly from the opening, extend (unroll) all of the screen fabric and on the A-Screen Cassette Assembly and

then retract the fabric making sure to remove any wrinkles or creases.

ANTI-WIND BRUSH PILE MOVES IN THE SIDE GUIDE RAILS

The Anti-Wind Brush Pile that is located inside the aluminum B-Inside Rails need to be crimped securely in place so that it does

not move within the channels of the B-Inside Rails (see step 4).

The L-PULL BAR LOCKS DO NOT CATCH ON THE D-PULL BAR

Adjust the height of the latch on the L-Pull Bar Locks using the wheel style finger adjustment. The engagement of the L-Pull Bar

Locks to the D-Pull Bar should match image 4C.

THE D-PULL BAR MOVES DURING WINDY CONDITIONS

Fasten the Pull Chain in the H-Chain Lock when the screen is resting in the fully up or down position.

Add an additional O-Weight Bar (or other ballast material) inside the D-Pull Bar.

Windy conditions may affect the performance of a retractable screen. Retract the screen in windy circumstances, during

inclement weather, when not needed to support immediate ventilation or during prolong periods when not used.

THE SCREEN IS TORN OR WRINKLED

Contact dealer to order a Screen Refill Replacement Kit

THE J-WEATHER STRIP DOES NOT SEAL AGAINST THE FLOOR/SILL

Check that the screen has been installed in a square and plumb opening. Correct the opening as needed.

Contact dealer to order the slightly larger optional Rubber Bulb Seal.

Adjust the height of the latch on the L-Pull Bar Locks using the wheel finger adjustment. The engagement of the L-Pull Bar Locks

to the D-Pull Bar should match image 4C.

Add an additional O-Weight Bar (or other ballast material) inside the D-Pull Bar.

Lower the screen tight to the floor/sill and then secure the Pull Chain in the H-Chain Lock.

WHEN RETRACTED THE L-PULL BAR WITH SCREEN FABRIC FALLS DOWN SEVERAL INCHES

Secure the Pull Chain in the H-Chain Lock when the screen is resting in the up position.

Add spring tension.

?Installation Questions ?Missing Parts ?Replacement Parts ?

Please call our Homeowner Helpline @ 1-888-483-3768

DON’T GO BACK TO THE STORE!

TROUBLESHOOTING GUIDE

Shorter Pile

Installation Questions? Missing Parts? Replacement Parts?

DON’T GO BACK TO THE STORE!

Please call our Homeowner HelpLine: 1-888-483-3768

ESCAPE 800 INSTALLATION INSTRUCTIONS