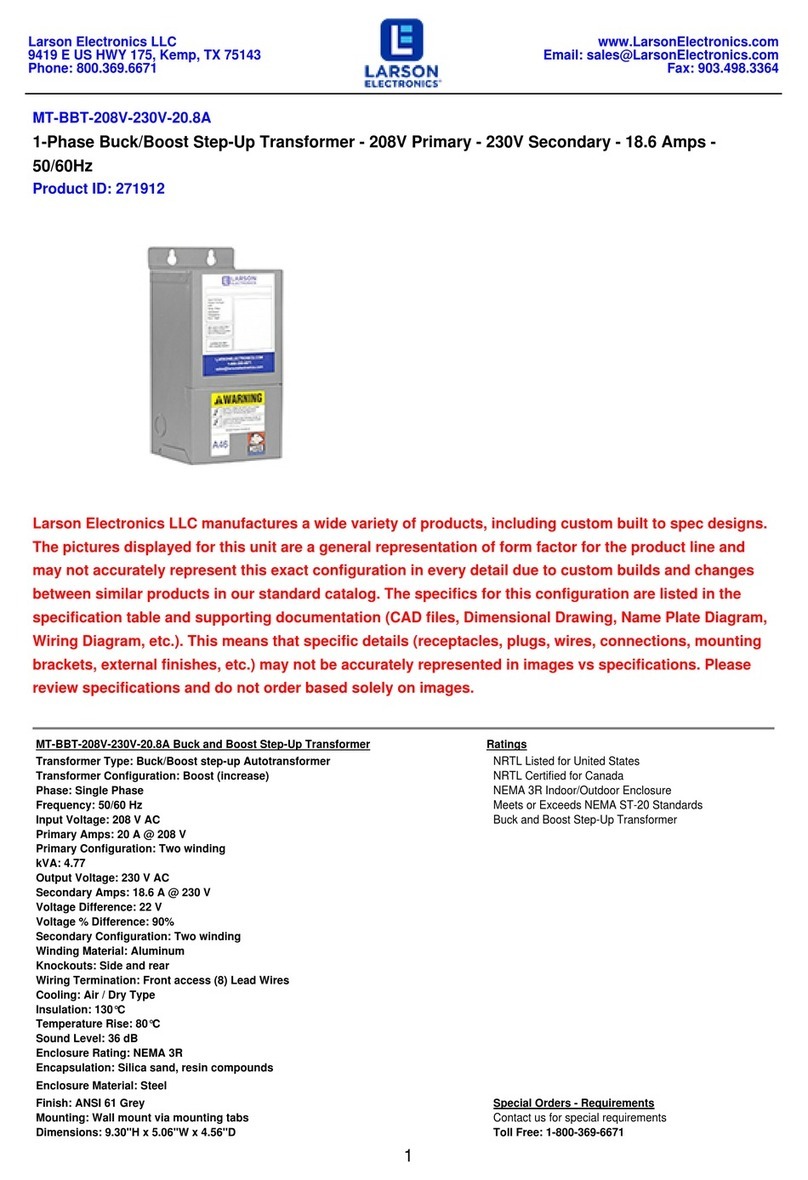

The MT-BBT-480Y-380Y.220-3P-781A Three Phase Step-Down Buck and

Boost Transformer from Larson Electronics is powerful, reliable, and

designed with the environment in mind. Suitable for both indoor and

outdoor applications, the MT-BBT-480Y-380Y.220-3P-781A provides

increased reliability, higher efficiency, protection against critical

equipment failures, and an extra level of protection by isolating the

power source from the connected device. The lower operating costs,

lower heat emissions and lower cost of ownership make this transformer

ideal for a wide range of applications and businesses.

*PLEASE NOTE: ANY FREE SHIPPING OFFERS DO NOT APPLY TO POWER

DISTRIBUTION PANELS, TRANSFORMERS, OR SUBSTATIONS*

Transformer Features: The MT-BBT-480Y-380Y.220-3P-781A buck and boost

transformer is a three phase unit with a 519 kVA rating and a primary voltage of

480 V Wye using a maximum of 625 amps on the primary side. This step-down

transformer has a secondary voltage of 380Y/220 V Wye and provides up to 781

amps available on the secondary side. Featuring robust construction, this unit's

cores are manufactured with non-aging, cold-rolled silicon steel laminations using

state of the art technology.

This unit boasts a low cost of ownership and is highly energy efficient. Lower heat

emissions mean less cooling is needed as well. The NEMA 3R painted steel

enclosure makes the unit suitable for both indoor and outdoor applications, and

this step-down transformer can be floor mounted. The MT-BBT-480Y-380Y.220-

3P-781A features a 220°C insulation with a 150°C temperature rise.

Construction: The copper winding in the MT-BBT-480Y-380Y.220-3P-781A are

formed from high quality copper wire help to improve performance. The close

tolerances used during manufacturing also eliminates burrs which hinder

performance. Each core is specially coated to prevent the ingress of moisture and

are electrically balanced to minimize axial forces during short circuit situations.

Buck and boost transformers are designed to maximize the performance and life

of electrical equipment. The MT-BBT-480Y-380Y.220-3P-781A is encapsulated in

silica sand and resin, and cased in a NEMA 3R steel enclosure. NEMA 4, NEMA 4X,

and NEMA 12 enclosures are available upon request.

Benefits: The MT-BBT-480Y-380Y.220-3P-781A buck/boost step-down

transformer offers many benefits to the consumer. Buck/boost transformers pass

the majority of the load voltage directly through the transformer, only

transforming a small percentage of the load. Due to this technology, a smaller and

quieter step-down transformer is manufacturered and uses less materials. This

provides owners with significant energy savings as well as offering environmental

benefits.

Higher efficiency not only extends the life of the transformer, but also turn into

cost savings for owners in the form of lower energy bills and decreased cost of

ownership. Installation and maintenance costs are reduced due to the smaller

form factor, and less overall space requiorments are decreased. In addition, these

step-down transformers operate quieter than a standard autotransformer of the

same capacity.

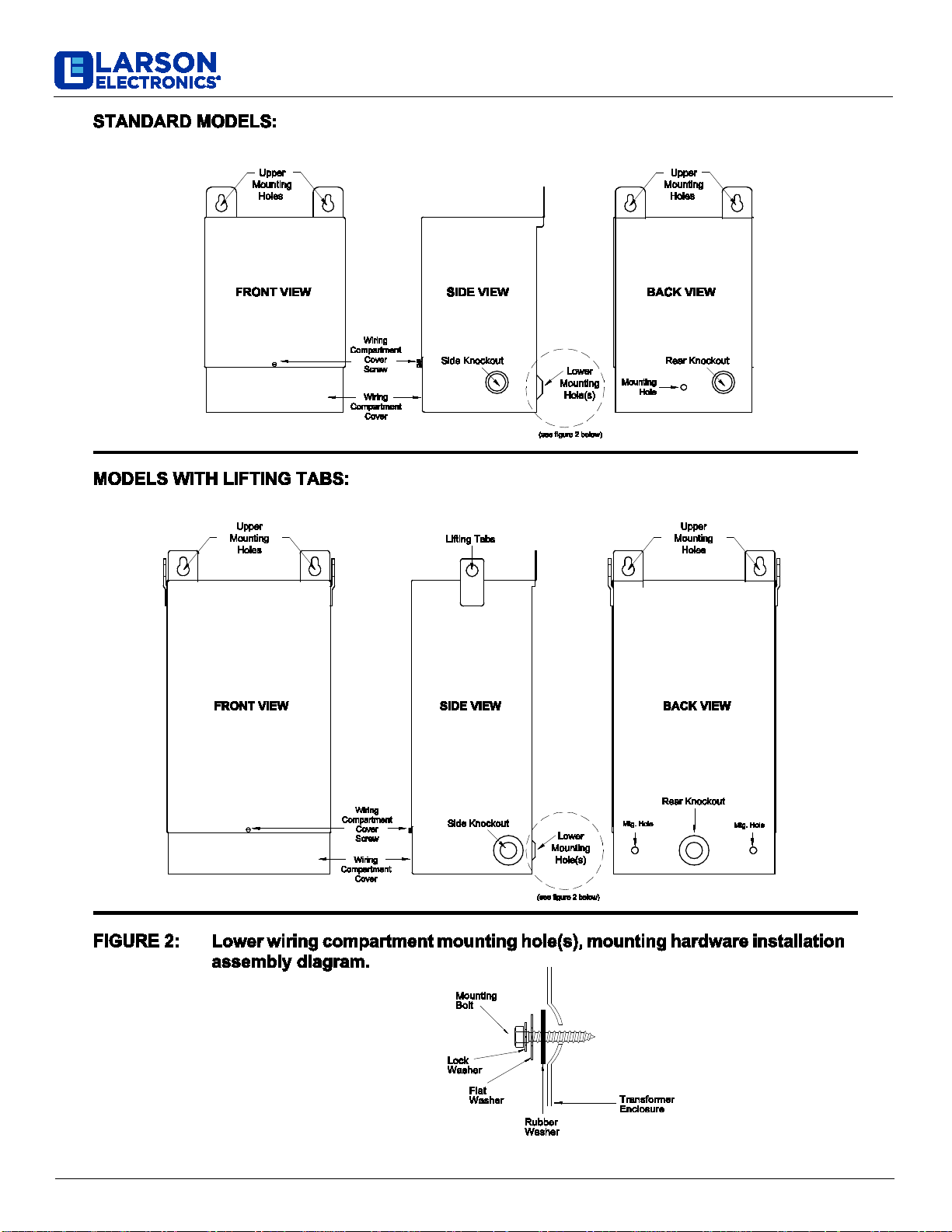

Mounting: Integrated floor mounting brackets make installation fast and easy.

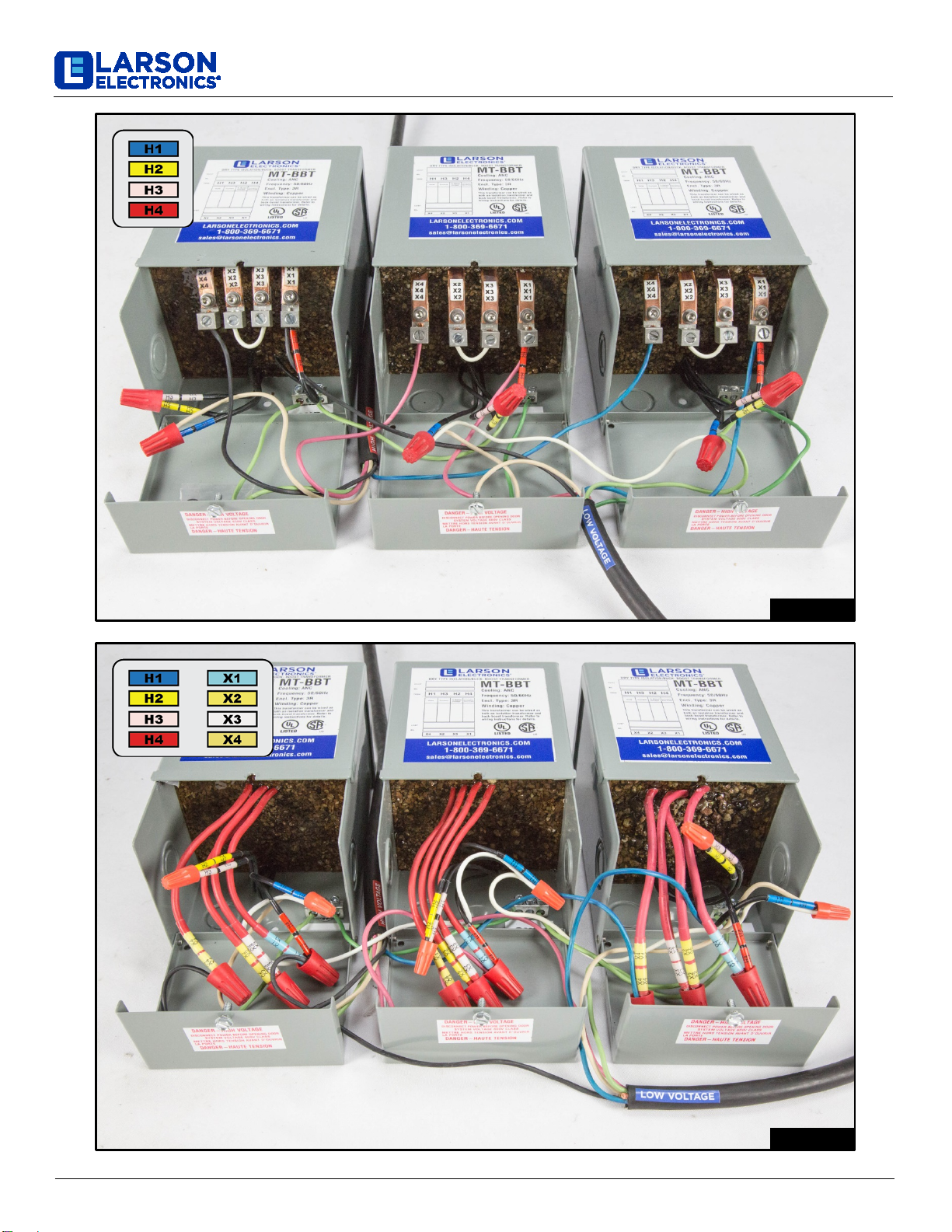

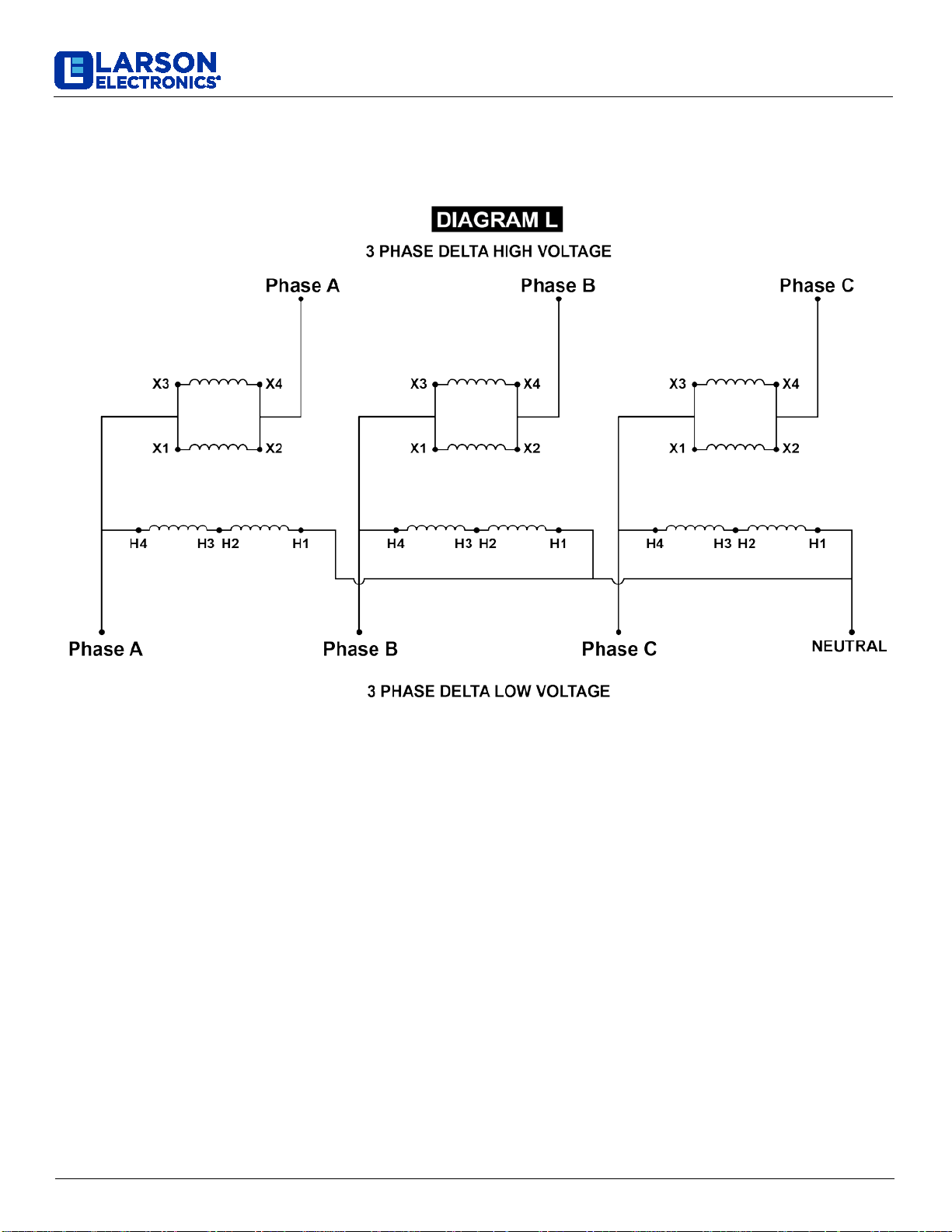

Installation: Installation is simple. Connect the primary leads and secondary

leads to the step-down transformer per the provided wiring diagram. Knockout

hubs on either side and the bottom of the transformer allow for easy line-in and

line-out wiring. The front access cover provides convenient access.

Applications: Air conditioners, lighting systems, heating elements, motor

applications and other applications that that require the ability to power loads that

differ from the available line voltage.

Limitations: While there are many benefits to a buck/boost transformer, there

are some limitations to consider. This transformer will only transformer voltage, it

will not convert phases, it will not create even legs between line 1 and line 2 (L1

and L2 WILL be UNEVEN), has no circuit isolation, and does not create a neutral

for applications where a neutral is not already present. If any of these limitations

apply to you, you will need a standard transformer. Please see below link for our

standard line of industrial transformers or our line of phase converters.

2

Larson Electronics LLC

9419 E US HWY 175, Kemp, TX 75143

Phone: 800.369.6671

www.LarsonElectronics.com

Fax: 903.498.3364