10 • LMH Series Rotary Lasers

X—AXIS ERROR

Y—AXIS ERROR

SPINDLE ERROR

X—AXIS ERROR

Y—AXIS ERROR

SPINDLE ERROR

LMH600

LMH

3.2 Re-leveling

If the unit is bumped or moved, the unit

will automatically attempt to re-level

itself. The Power On LED and the laser

will blink during this process until the

unit is level once again. The laser head

will resume rotation.

On the job site, it may be necessary to

prevent re-leveling in order to prevent

inaccurate measurements by the opera-

tor. The LMH’s Anti-Drift System (Section

3.3) is used for this purpose.

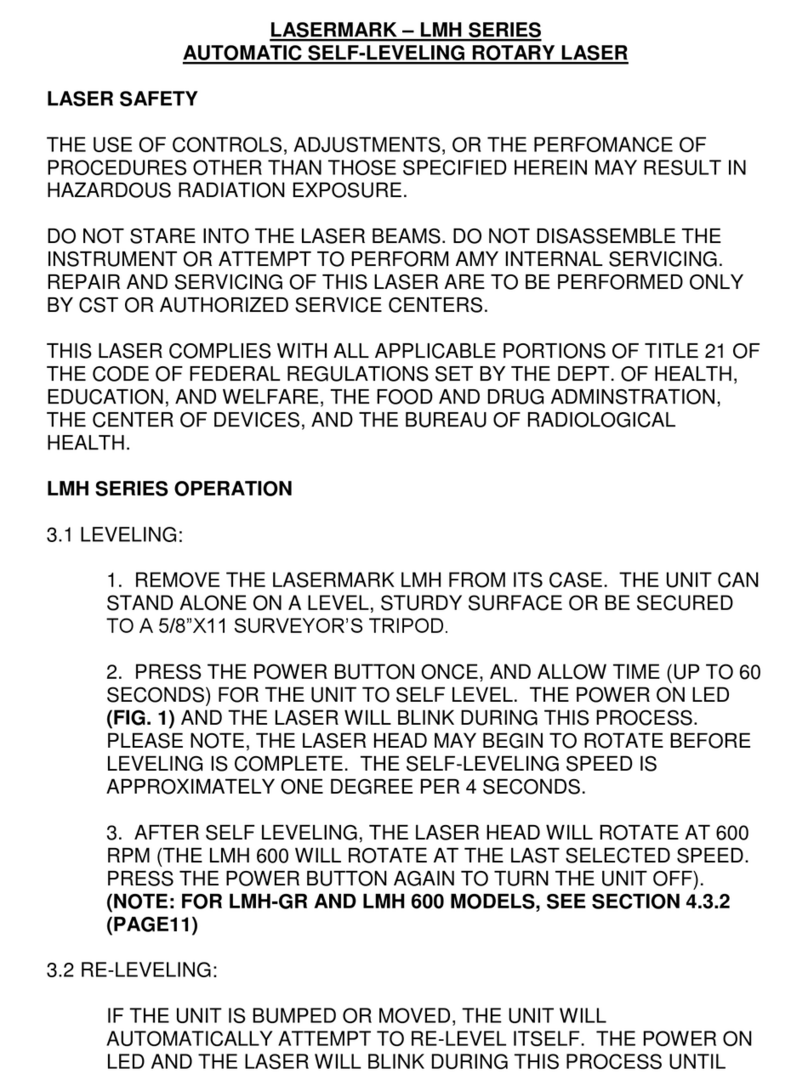

3.2.1 Axis Drive Error

If the LMH is set up or tipped beyond its

self-leveling range of ±5°, the laser head

will initially attempt to level; however,

when the self-leveling limit is reached,

the LEDs will blink, indicating an axis

drive error (Fig. 2). Turn the LMH off,

move the unit into a more level position,

then turn the unit on again.

3.3 Anti-Drift System (ADS) (LMH, LMH-C, and LMH-GR only)

By default the ADS feature is ON. The default setting of the ADS func-

tion may be set to ON or OFF. When the unit is OFF, press and hold

the MANUAL MODE (for LMH-GR, DOWN ARROW button) and then press

the POWER button. Once the unit is on, turn the unit off for 15 Sec

and then back on. ADS will not be the default when unit is turned ON.

To make the unit return to ADS as default, repeat these instructions.

When the LMH Series laser is first turned ON, the ADS feature does not

begin recording for 1 minute. This allows the instrument to be set up

and adjusted.

If after 1 minute, the unit is disturbed and the ADS light is flashing

it is necessary to check any bench marks that have been made and

ensure the proper "HI" (Height of Instrument). After the flashing ADS

has been reset, by pressing the ADS button one time, you will have an

additional minute to set and check your measurements. To turn ADS

off press the ADS button once. This will put the unit into normal Auto

Self-Leveling mode.

Fig. 2