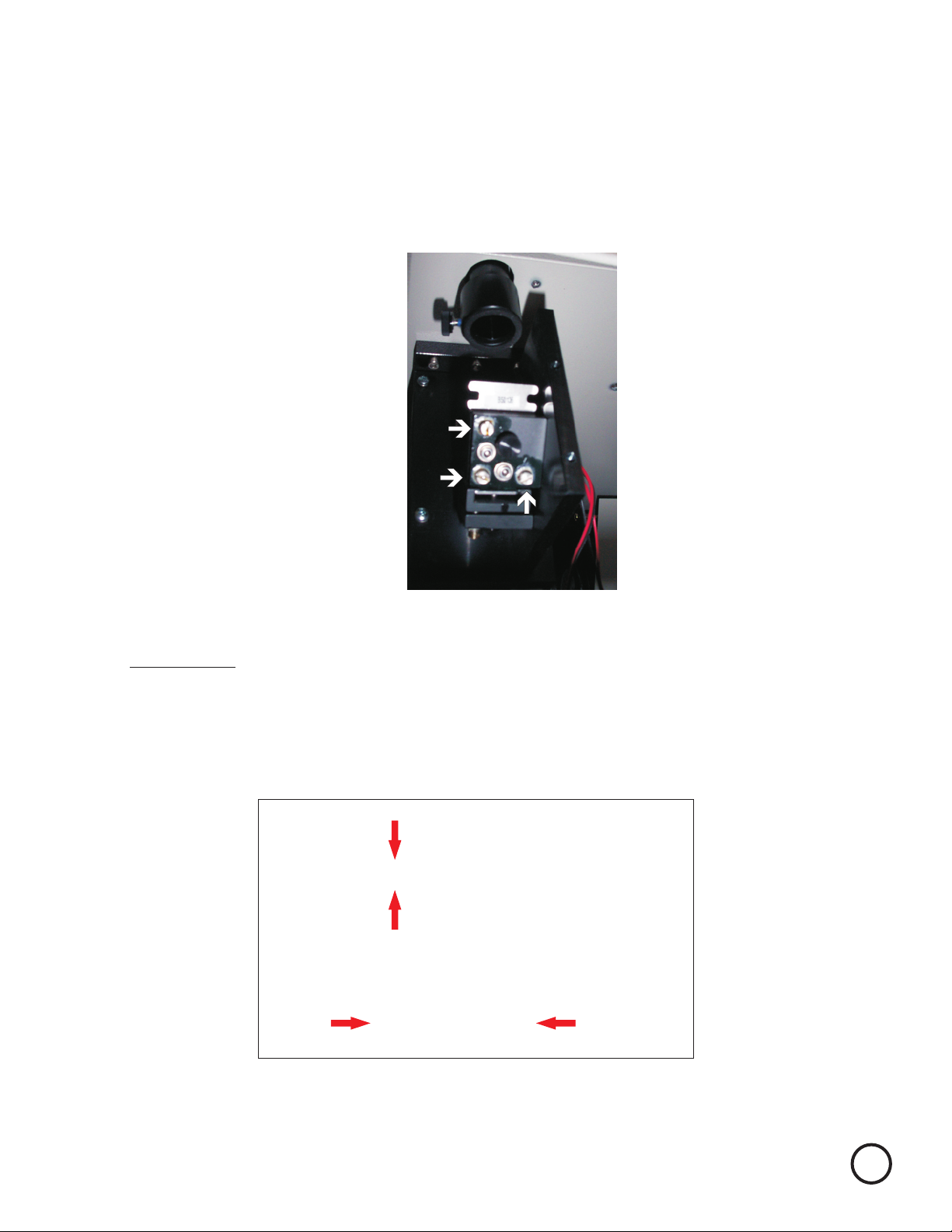

Prism Mount for Mirror 2

(Looking from back of laser with lid off and cover shifted to right)

Screw 1

Pivot Screw do not adjust

Screw 2 Up and Down

Left and Right

Prism Mount

Screw 1

Screw 2

Pivot Screw

Mirror

Once mirror 2 is adjusted we will now repeat all the steps to check and adjust P3 to P4. Do not forget

to remove tape from back of mirror 3. Place your tape on the lens carriage in front of Mirror 4.

As before P3 burn position will not move. Your goal is to get the dot from P4’s firing to line up on top

of P3’s. The difference here is P4 is so far away the beam gets quite large. The burn mark will take

longer to form and the dot is much larger. Burn in P4 1st to make visibility easier. Adjust the prism

mount of mirror 3 by opening up access panel as seen in picture on following page.

Follow the same process as used on mirror 2.

Repeat until P3 falls on top of P4.

You are almost done.

Once you have adjusted the prism mount run the P2 burn again. If it lands on top of your original

P1 burn your done. If not re-adjust to correct. You may wish to use a new piece of tape and run P1

and P2 again. Repeat as often as necessary until P2 line up directly on top of P1

Lock Screw

Lock Screw

Lock Screws must be tightened when adjustments completed. Adjustments should

be made with lock screws snug, they may need to be loosened slightly if adjustment

is made on screws 1 or 2 in a clockwise direction. (Please note tightening up Lock

Screws may affect beam alignment adjust alignment as necessary)

Remember to always wear safety glasses while doing any open beam tests. 6