F 7.3.12 - 0312 Data Sheets are subject to change without notice. For latest revision, check our website at www.laticrete.com. DS-034.0-0412

Installation may be made on a damp surface. Expansion joints shall

be provided through the tile work from all construction or

expansion joints in the substrate. Follow ANSI specification A108.01-

3.7: Requirements for Movement Joints: Preparations by Other

Trades” or TCNA detail EJ-171 “Movement joints-Vertical &

Horizontal”. Do not cover expansion joints with mortar.

Typically Linear Drains should run from sill plate to sill plate (the

width of the shower) against a wall (see ES-B415LD Bonded Corner

Placement). Alternatively they can also be placed in medial locations

(see ES-B415LD Unbonded Medial Placement) or at the shower

entrance. In all locations the waste line for standard size

LATICRETE®Hydro Ban®Linear Drains are in the center of the linear

drain. When installed against a wall the center of the waste line

should be located far enough away from the sill plate to

accommodate wall sheathing and finished tile surface. For 1/2" (12

mm) wall board and 3/8" (9 mm) tile the center of the waste line

should be located 2 1/4" (57 mm) out from the sill plate.

Mortar Bed—Installation over concrete (see ES-B415LD Bonded

Corner Placement and ES-B415LD Unbonded Medial) For a Bonded

mortar bed over concrete installation, before placing mortar, apply a

slurry bond coat made from LATICRETE 254 Platinum or LATICRETE

4237 Latex Additive mixed with LATICRETE 211 Powder. While the

slurry bond coat is wet, spread LATICRETE 3701 Fortified Mortar Bed

and compact well. Bonded mortar beds over concrete shall be 3/4"(19

mm) minimum to 2"(50 mm) maximum. For an unbonded installation

over concrete (see ES-415LD Unbonded Medial) a cleavage

membrane as specified in ANSI A108.02-3.8 should be used in place

of the slurry bond coat. The LATICRETE 3701 Fortified Mortar Bed

should be reinforced with 2" x 2" (50 x 50 mm) reinforcing mesh.

Unbonded Mortar beds over concrete shall be 1-1/4"(32 mm) minimum

to 2"(50 mm) maximum. In both Bonded and Unbonded mortar Bed

installations place enough LATICRETE 3701 Fortified Mortar Bed

where the linear drain will be set to support the bottom and under the

flanges of the drain trough. Minimum height from the flange to the

substrate should be 1-1/2" (37 mm). Make the connection to the waste

line when the drain is set into place using a no hub connection (not

supplied), see installation instructions below. Next place a ribbon of

LATICRETE 3701 Fortified Mortar Bed along the opposite wall to

create a 1/4" (6 mm) per foot slope to the LATICRETE Linear Drain. Fill

the area between the drain and the walls with LATICRETE 3701

Fortified Mortar Bed; screed and compact well. Mortar beds in excess

of 2"(50 mm) thick shall be detailed by the architect per TCNA F112.

Mortar Bed –Installation over Exterior Glue Plywood ( EGP) (see

ES-415LD EGP Bonded Corner Placementl and ES-415LD EGP

Unbonded Medial Placement)

For a bonded mortar bed over EGP installation, before placing

mortar, install a cleavage membrane as specified in ANSI A108.02-

3.8. Expanded metal lath (minimum 2.5 pounds (1.1 kg)/square yard

(0.8 square meters) and complying with ANSI A108.02 3.6) is then

nailed or stapled to the subfloor over the cleavage membrane.

Following the lath spread LATICRETE 3701 Fortified Mortar Bed and

compact well. Bonded mortar beds over EGP shall be 3/4"(19 mm)

minimum to 1 1/2"(38 mm) maximum. For an unbonded installation

over EGP (see ES-415LD EGP Unbonded Medial Placement) install

a cleavage membrane as specified in ANSI A108.02-3.8 and then

spread the LATICRETE 3701 Fortified Mortar Bed. In both bonded

and unbonded mortar bed installations place enough LATICRETE

3701 Fortified Mortar Bed where the linear drain will be set to support

the bottom and under the flanges of the drain trough. Minimum height

from the flange to the substrate should be 1-1/2" (38 mm). Make the

connection to the waste line when the drain is set into place using a

no hub connection (not supplied). Next place a ribbon of LATICRETE

3701 Fortified Mortar Bed along the opposite wall to create a 1/4" (6

mm) per foot slope to the LATICRETE Linear Drain. Fill the area

between the drain and the walls with LATICRETE 3701 Fortified

Mortar Bed; screed and compact well. Mortar beds in excess of 2"(50

mm) thick shall be detailed by the architect per TCNA F112.

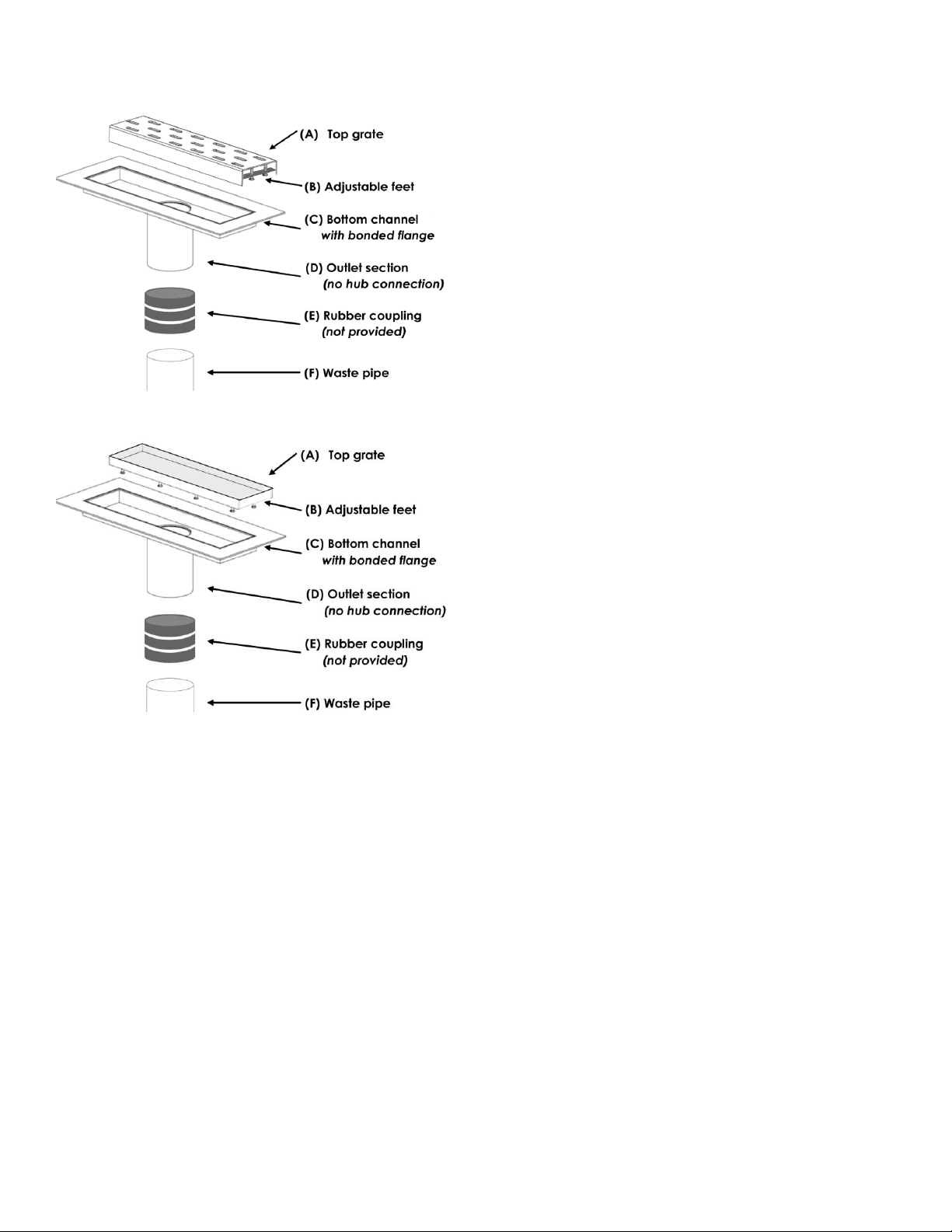

Installation Instructions (Fig. 1)

1. Connect outlet (D) to waste pipe (F) via 2"(50 mm) no hub

connection using a rubber coupling (E) (not provided). Note:

outlet section (D) is 3"(76 mm) long and can be modified for

height adjustment. Grate A has adjustable feet for finer

adjustment (Minimum tile height with thin-set is 3/8"(10 mm),

maximum tile height is 3/4"(19 mm)).

2. Using a LATICRETE 3701 Fortified Mortar Bed set and level

channel (C)

3. Spread LATICRETE 3701 Fortified Mortar Bed, slope 1/4" per

foot (19mm per m) away from drain in a single plane. Note: tile

height should finish 1/16"(1.5 mm) higher than grate height the

tile in the Tile in Drain Grate.

4. When the mortar is dry install backer board per manufacturer’s

instructions. The backer board will sit on the drain flange and

mortar (see ES-B415LD Bonded Corner Placement or ES-

B415LD EGP Bonded Corner Placement).

5. After the backer board has been installed waterproof the

installation using LATICRETE Hydro Ban per instructions in

DS663.0 and 663.5. The stainless steel from the linear drains

needs to be clean and free of any grease, dirt or fingerprints

prior to coating with Hydro Ban. The LATICRETE Hydro Ban

should cover the metal flange on the linear drain trough to the

top of the first radius and extend up the walls and over the entire

mortar bed. If the gap between the linear drain flange and the

wall board is larger than 1/8" (3 mm) it should be filled with a

LATICRETE Polymer Modified Thin-Set e.g. LATICRETE 254

Platinum) or alternatively use 6" (150 mm) wide LATICRETE

Waterproofing/Anti-Fracture Fabric imbedded into the

LATICRETE Hydro Ban around four sides of the linear drain

overlapping the flange and the LATICRETE 3701 Fortified

Mortar Bed. Lap LATICRETE Waterproofing/Anti-Fractrure

Fabric and LATICRETE Hydro Ban liquid up the wall when

adjacent to show¬er wall and over wall board. DO NOT

waterproof the inside walls and bottom of the linear drain

channels.

6. Take measures to protect grate (A) prior to tiling. Keeping the

grate (A) in the channel (C), thin-set and tile on the waterproof

membrane. Ensure tile allows for clearance of grate (A)

removal. Tile finishes 1/16"(1.5 mm) higher than grate or the tile

in the Tile in Drain Grate.

7. If the grate has adjustable feet then adjust grate (A) height with

adjustable feet (B) as needed.

8. When installing the LATICRETE Hydro Ban Linear Tile Drain

Grate (A) will need to be primed with two coats of LATICRETE

Hydro Ban prior to thin-setting the tile into the top grate. The

stainless steel from the linear drains needs to be clean and free

of any grease, dirt or fingerprints prior to coating with Hydro

Ban.

9. When the second coat of LATICRETE Hydro Ban is dry the

installation can be tiled using a LATICRETE polymer fortified