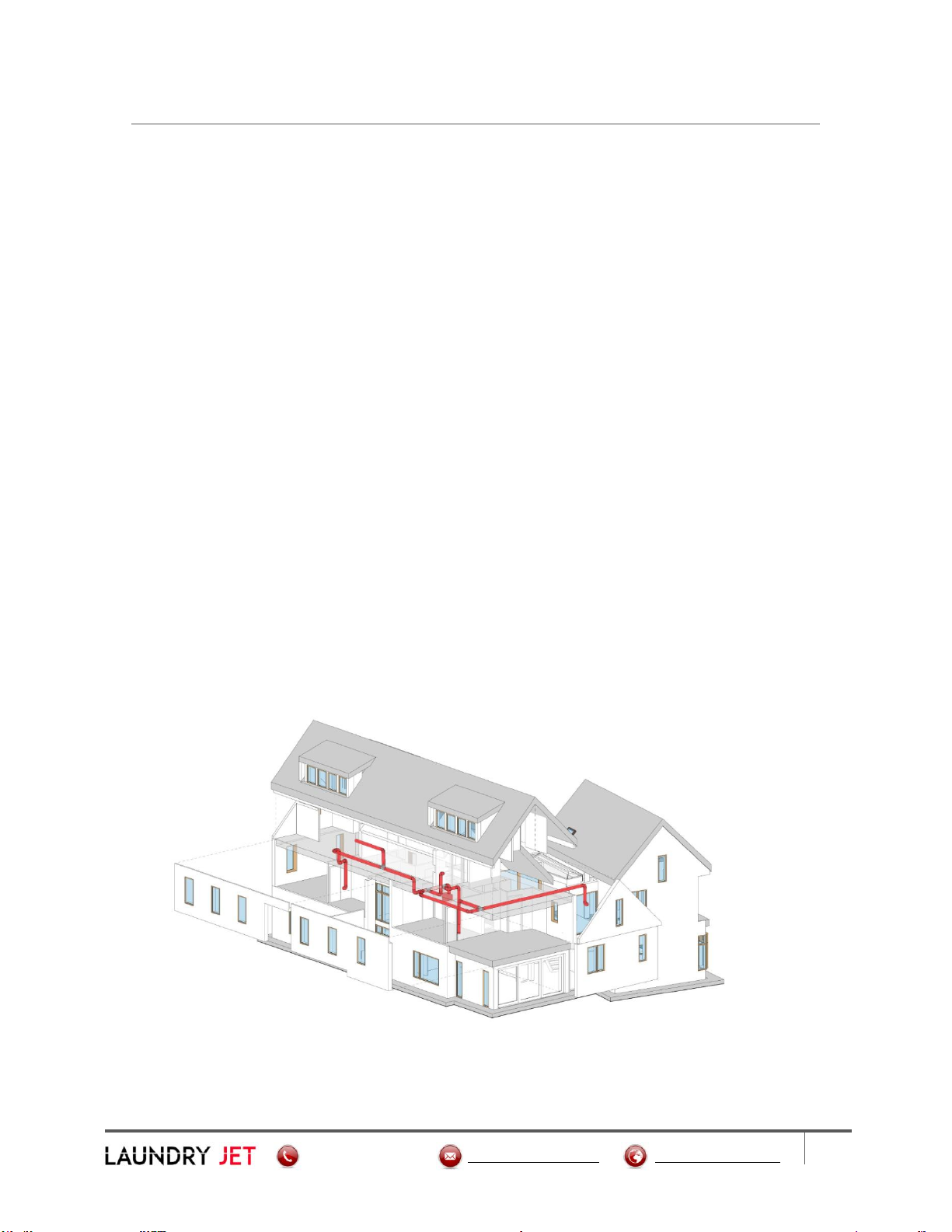

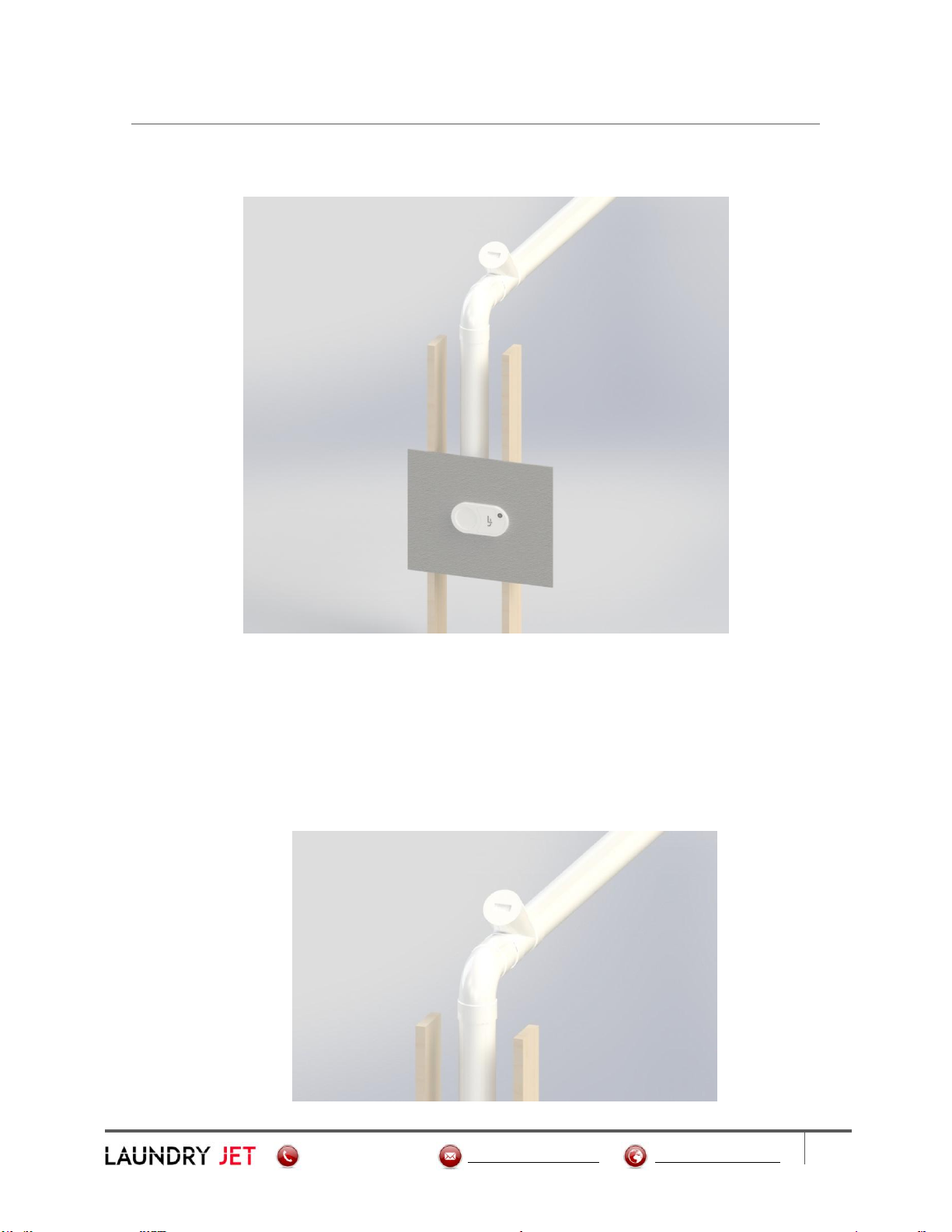

Pipe Installation Standards

4.1 Pipe Installation Overview

Pipe Installation Standards

Required Piping Installation Standards

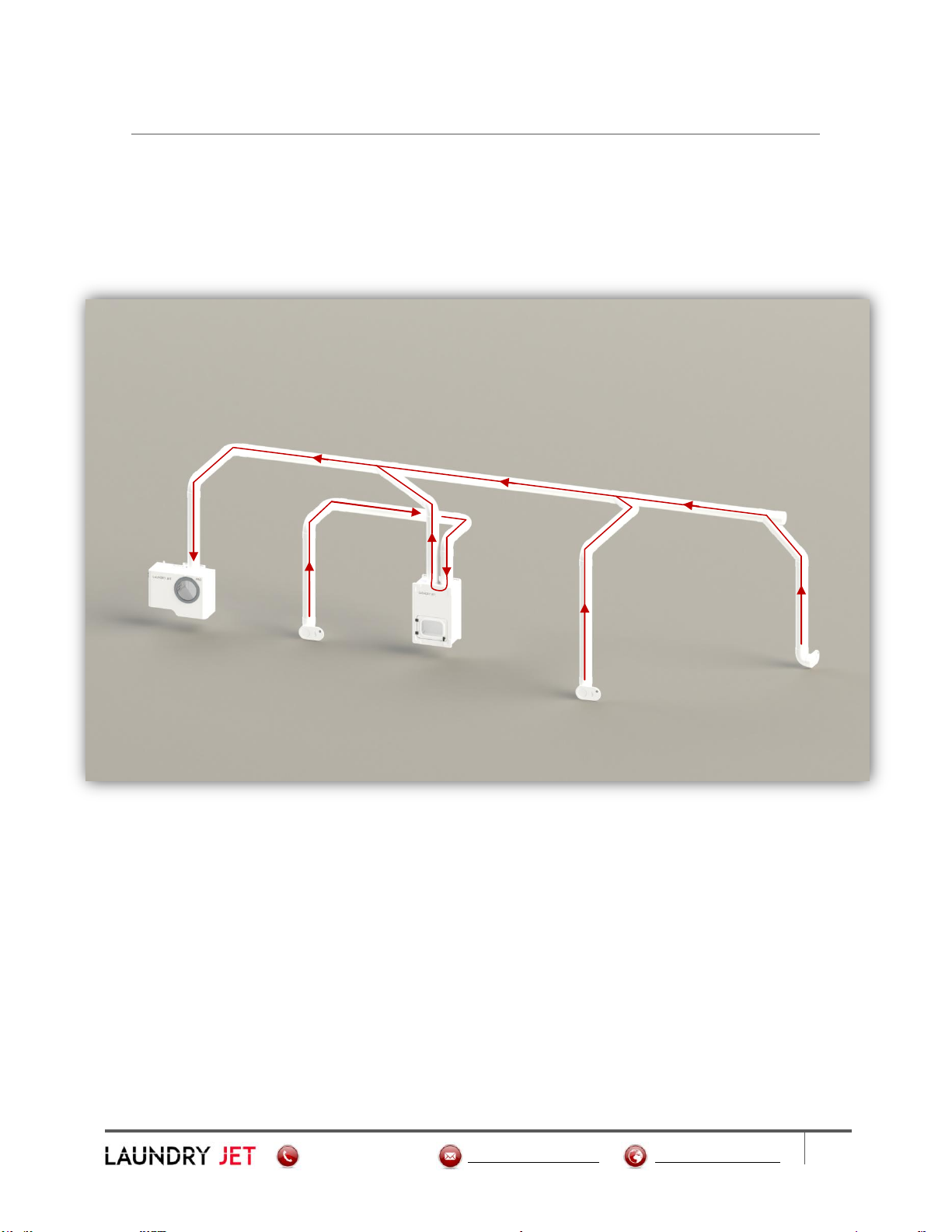

▪All joints must use a minimum entry angle of 45 degrees with a break distance of 18 Inches

(460 MM). See Image below.

▪Pipe cuts must be straight and de burred before seating.

▪Pipe must be completely seated in fitting connections.

▪Seal all joints using standard PVC glue.

Connections must be glued around 360 degrees

to ensure maximum system performance.

▪System must be strapped with “plumbers tape”

(or equivalent) every 6 feet. Port 90 must be

strapped and secured prior to Port installation.

▪Install Cleanout ports every 50 feet on angled runs. Straight trunk lines can run up to 100

feet with cleanouts at either end.