LawnMaster PB Series Installation manual

SAFETY AND OPERATING MANUAL

PLEASE READ THIS MANUAL CAREFULLY BEFORE OPERATING THE UNIT

PB SERIES GENERATORS

OPEN FRAME

GENERATORS

PROUDLY

NZ OWNED

A STEELFORT PRODUCT

2A STEELFORT PRODUCT | STEELFORT.CO.NZ

I. OPERATOR SAFETY

II. GETTING STARTED

SAFETY RULES

UNPACKING

ASSEMBLY

FEATURES & CONTROLS

III. OPERATING

OPERATING ENVIRONMENT

OPERATING CONDITIONS

OIL CHECK

ENGINE FUEL

LECTRICAL DEVICES

GROUNDING

STARTING THE ENGINE

CONNECT ELECTRICAL DEVICES

BEARING CAPACITY

CHARGING THE BATTERY

STOPPING THE ENGINE

LONG DISTANCE CONTROL

IV. MAINTENANCE

MAINTENANCE SCHEDULE

GENERATOR MAINTENANCE

ENGINE MAINTENANCE

V. STORAGE & TRANSPORTATION

VI. TROUBLESHOOTING

VII. SPECIFICATIONS

SPECIFICATIONS PARAMETER TABLE

WIRING DIAGRAM

VIII. WARRANTY

TABLE OF CONTENTS

3

A STEELFORT PRODUCT | STEELFORT.CO.NZ

I. OPERATOR SAFETY

SAFETY RULES

This manual contains important safety information

and instructions to operate the LawnMaster Inverter

Generator.

PLEASE READ THIS MANUAL CAREFULLY BEFORE

USING THE UNIT.

Failure to adhere to the safety instructions could

result in property damage and/or serious personal

injury.

This manual should be considered a permanent part

of the generator and should remain with the unit at

all times. All information in this publication is based

on the latest product information available at the

time of printing.

Product Information and specications can be

altered and/or improved without notice.

Content from this publication may not be reproduced

without written consent.

DANGER

Indicates a hazardous situation which, if not strictly

complied with, will result in substantial property

damage and or serious injury.

WARNING

Indicates a hazardous situation which, if not strictly

complied with, may result in property damage

CAUTION

Indicates a hazardous situation which, if not strictly

complied with, could result in property damage or

personal injury.

The warnings and precautions discussed in this

manual does not cover all possible conditions and or

scenarios that may occur.

It must be understood by the operator that common

sense and caution must be taken into consideration

when operating this product, as these are factors

which cannot be built into this manual.

WARNING

This generator is intended for domestic consumer

use only. Damage and faults created from

commercial use may void warranty. These generators

are designed for full time operation. No personal

modications should be made to any part of the unit.

DANGER

TOXIC FUMES

• The exhaust of the engine contains carbon

monoxide, an odorless, colorless poison gas.

Using the engine in conned/indoor spaces can

be extremely dangerous and life threatening.

• DO NOT use the generator inside and or in

enclosed spaces EVEN IF doors and windows

are open. Only use the engine in well

ventilated areas and consider wind and airow

when positioning the engine.

KICKBACK

• Rapid retraction of the starter cord will pull

hand and arm towards the engine faster than

you can let go. Unintentional startup can result

in serious injury.

FIRE

• When operating the unit, the engine may create

sparks that could trigger res.

• When operating around dry vegetation such as

agricultural crops, forest, bush, grass, or other

similar environments please be careful.

• This engine may not be equipped with a spark

arresting muer. In some countries and

regions, a spark arrester is required by law.

Please contact your local council and or re

agency for laws and regulations relating to re

prevention requirements.

• Petrol is highly ammable and explosive. A

re and or explosion from petrol can cause

severe burns or result in serious personal injury

including death.

• Keep ammable items away while handling

petrol. Fill fuel tank outdoors and in a well

ventilated area with the engine stopped.

• Always wipe spilled fuel and wait until the fuel

has dried before starting the engine.

• DO NOT operate the engine with known leaks

in the fuel system. Use proper fuel storage and

handling procedures.

• DO NOT store fuel or other ammable materials

near the generator.

4A STEELFORT PRODUCT | STEELFORT.CO.NZ

• Empty the fuel tank before storing or

transporting the generator. Keep re

extinguisher handy at all times.

BATTERY

• Lithium battery is maintenance free, if you have

any question, please contact a local authorised

dealer.

HOT SURFACE

• Running the generator will produce heat and

severe burns may occur upon contact. DO NOT

touch the engine while under operation or just

after stopping the unit.

• Avoid contact with hot exhaust gases and or

hot surfaces.

• Maintain at least 1m of clearance on all sides

to ensure adequate cooling. Combustible

material can catch re upon contact. Maintain

at least 3m of clearance from combustible

materials.

MOVING PARTS

• Moving parts can cause severe injury. Keep

hands and feet away from the unit.

• DO NOT operate engine with covers, shrouds,

or guards removed.

• DO NOT wear loose-tted clothing, dangling

drawstrings or items that could become caught

or entangled.

• Tie up long hair and remove jewelry. The

moving parts may catch operator’s hand, feet,

hair and or loose clothing resulting in serious

injury.

GENERAL WARNINGS

• Before use, check for loose or damaged parts,

signs of oil or fuel leaks, and any other

condition that may impact operation.

• Repair or replace all damaged and or defective

parts immediately.

• Locate all operating controls and safety labels.

• Make sure all the safety instructions are in

correct working condition.

• Operate only on level surfaces.

• DO NOT expose the generator to excessive

moisture, dust, and or dirt.

• Keep all safety guards in place and in proper

working order at all times.

• DO NOT allow any material to block the cooling

slots.

• DO NOT allow children or untrained people to

operate the unit.

• DO NOT leave the generator unattended when

it is in operation. Always turn off the generator

prior to leaving the area.

ELECTRIC SHOCK

• The generator produces powerful voltage and

the electricity and can be dangerous and cause

serious life threatening injuries if an electric

shock is received.

• Please ensure that the unit is properly

connected to an appropriate ground to help

prevent electric shocks.

• Failure to properly ground the unit can result

in electrocution, especially if the generator

is equipped with a wheel kit. Consult an

electrician for local grounding requirements.

• Installation should be performed by a certied

electrician. Improper Installation could result in

serious injury.

• To reduce the risk of electric shocks. DO NOT

use electrical cords that are worn, frayed, bare

or otherwise damaged.

• DO NOT touch bare wires or receptacles.

• DO NOT operate the unit in wet weather.

• Keep the generator dry and DO NOT handle

generator or electrical cords while standing in

water, while barefoot, or while hands or feet

are wet.

• Keep children or pets away.

• DO NOT plug the unit into a building electrical

system without the proper use and installation

of a transfer switch installed by a qualied

electrician.

• When using the generator for backup power,

notify your utility company.

• Use approved transfers to isolate generator

from electric utility.

• Failure to isolate the unit from the power utility

could result in serious injury to the staff and

utility workers due to back-feed of electrical

energy.

5

A STEELFORT PRODUCT | STEELFORT.CO.NZ

II. GETTING STARTED

1. UNPACKING

Remove the generator from the carton.

1. Place the carton on a solid, at surface.

2. Carefully cut each corner of the carton box from

top to bottom. Fold each side at on the ground.

3. Remove everything from the carton except the

generator.

2. ASSEMBLY

Your generator may require some assembly. If

you have any questions regarding the assembling

process of the generator, please consult your local

dealer for help.

2.1 INSTALL WHEEL KIT

Put wheel stop pin through the wheel and mounting

lug hole, then x it with the clamp.

Note: A at washer may be used to adjust the

assembly clearance as needed.

2.2 INSTALL SUPPORT BRACKET

The sealed battery on the generator is fully charged

and pre-installed except for the negative (black)

battery cable.

2.3 INSTALL HANDLES

Use the handle pin across the handle and its mount-

ing lug hole, and then x it with the clamp.

6A STEELFORT PRODUCT | STEELFORT.CO.NZ

The sealed battery on the generator is fully charged and pre-installed except for the negative (black) battery

cable.

INSTALL:

• Cut off tie wrap that is securing the loose end of negative (black) cable. Connect the negative (black)

battery cable to the negative(-) terminal on the battery.

• Verify if it is correct and secure the connections between the battery and generator.

2.4 CONNECT NEGATIVE BATTERY CABLE

7

A STEELFORT PRODUCT | STEELFORT.CO.NZ

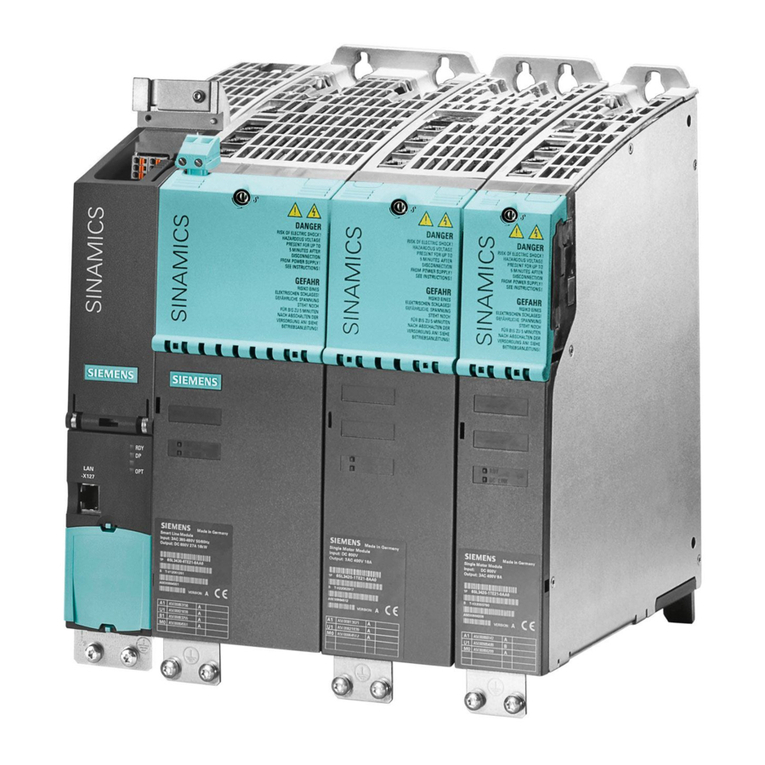

3. FEATURES & CONTROLS

8A STEELFORT PRODUCT | STEELFORT.CO.NZ

III. OPERATING

1. OPERATING ENVIRONMENT

• Only use OUTSIDE and operate the generator

in well-ventilated areas. Only operate the

generator on at, level surfaces and in a clean,

dry operating environments.

• Allow 1m clearance on all sides of the

generator while operating outdoors.

• Operate in safe and specied areas.

• Generator’s used in construction sites may be

subject to additional rules and regulations.

DANGER

TOXIC FUMES

• The exhaust of the generator contains carbon

monoxide, using the generator indoors can be

extremely dangerous.

• DO NOT use the generator inside any buildings

or any kind of enclosure, EVEN IF doors and

windows are open. Place the generator in a

well-ventilated and clean areas. Think of the

wind direction and airow when placing the

unit for operation.

HIGH ALTITUDE

• This generator may require a high altitude

carburetor kit to ensure correct operation at

higher altitudes. Consult your local authorised

dealer for more information on high altitude

kits if you intend to operate the unit at altitudes

above 5,000 feet (1,500 meters).

CAUTION

• Even with carburetor modications, the genera-

tor horsepower will decrease by 3.5% for every

1,000 feet (300 meters) increase in altitude.

The effect of altitude on horsepower will be

greater than this if no carburetor modication

is made.

• Operating the unit at altitudes below 5,000 feet

(1,500 meters) with a modied carburetor may

cause the generator to overheat and result in

serious engine damage. Please restore factory

specications of the carburetor with a service

dealer when planning to use the engine in a low

altitude areas.

2. OPERATING CONDITION

Check for loose or damaged parts, signs of oil or fuel

leaks, and any other condition that may affect proper

operation. Repair and or replace with genuine parts

immediately.

WARNING

• Failing to correct problem(s) before operation

could result in property damage, and serious

injury.

• Remove any excessive dirt or debris, especially

around the muer and recoil starter.

• DO NOT move or tip the generator during

operation.

• Use generator only for intended use. If you

have questions about intended use, ask your

local dealer.

3. OIL CHECK

• Place the engine on a level surface with engine

stopped.

• Remove the dipstick and wipe it clean.

• Reinstall dipstick into tube; rest on oil ll neck,

DO NOT thread cap into tube.

9

A STEELFORT PRODUCT | STEELFORT.CO.NZ

• Remove the dipstick again and check oil level.

Level should be within the upper limit and lower

limit range on dipstick.

• Fill to the upper limit (marked with “H”) of the

dipstick with the recommended oil if the oil

level is low.

• Reinstall and fully tighten the dipstick.

• Refer to add oil instruction in MAINTENANCE

section for more information.

Oil capacity (rated):

See parameters.

WARNING

• Oil is a major factor affecting performance and

service life.

• We recommend using LawnMaster 4-Stroke

10W30 Oil (PP01020005). You can nd more

information about this in the MAINTENANCE

section of this manual.

• OIL MUST BE PLACED IN ENGINE BEFORE

STARTING. This engine is not lled with oil at

the factory. Any attempt to crank or start the

engine before it has been properly lled with

the recommended type and amount of oil may

result in engine damage and void your warranty.

CAUTION

Operate generator only on leveled surfaces. The

engine is equipped with a low oil sensor (applicable

types) that will automatically stop the engine when

the oil level falls below the safe limit. To avoid the

inconvenience of an unexpected shutdown, ll to

the upper limit and check the oil level regularly.

4. ENGINE FUEL

• With the engine stopped, check the fuel level

gauge. Rell the fuel tank if necessary.

• Use clean, fresh, regular unleaded petrol.

• DO NOT mix oil with petrol.

• Always wipe up any spilled fuel.

• Be sure not to ll above the upper limit mark

• Always allow room for fuel expansion.

Fuel capacity (rated):

See parameters.

DANGER

Do not ll the fuel tank above the upper limit. Over

lling will result in damage to the carbon canister (if

equipped) and void your warranty.

DANGER

• Petrol is highly ammable and extremely

explosive. Keep ammable items away while

handling petrol. Fill fuel tank outdoors and in a

well ventilated area with the generator stopped.

• Always wipe off spilled fuel and wait until the

fuel has dried before starting the generator.

• DO NOT operate the generator with known

leaks in the fuel system.

• Use proper fuel storage and handling proce-

dures. DO NOT store fuel or other ammable

materials nearby. Empty the fuel tank before

storing or transporting the generator.

• Keep re extinguisher handy and be

prepared if a re starts.

• NEVER use engine or carburetor cleaner

products in the fuel tank or permanent damage

may occur.

• It is important to prevent gum deposits from

forming in essential fuel system parts, such

as the carburetor, fuel lter, fuel hose or tank

during storage.

• Also, experience indicates that

alcohol-blended fuels (such as gasohol, etha-

nol or methanol) can attract moisture, which

leads to separation and formation of acids

during storage.

• Acidic fuel can damage the fuel system of the

generating set while in storage. Be sure to re-

view the instructions given in “Storage” section.

• Petrol/Alcohol Blends: up to 10% alcohol, 90%

unleaded petrol by volume is approved as a

fuel. Other petrol/alcohol blends are not ap-

proved. Damage and effects taken place from

using old, stale or contaminated fuel will not be

covered by warranty.

10 A STEELFORT PRODUCT | STEELFORT.CO.NZ

CAUTION

• To minimize gum deposits in your fuel system

and to ensure easy starting, do not use petrol

left over from the previous season.

• Pressure can build up in the fuel tank. Allow

the generator to cool for at least two minutes

before removing fuel cap. Loosen the fuel cap

slowly to relieve any pressure in the tank

5. ELECTRICAL DEVICES

Disconnect all electrical devices from the generator

and switch off the AC circuit breaker before starting

the engine.The generator may nd it hard to start

with electrical devices connected.

6. GROUNDING

The generator must be properly connected to an

appropriate ground. It helps prevent electrical shocks

if a ground fault condition exists in the generator or

in connected electrical devices, especially when the

unit is equipped with a wheel kit. Proper grounding

also helps dissipate static electricity, which often

builds up in ungrounded devices.

DANGER

ELECTRICAL SHOCK

Failure to properly ground the generator can result in

electric shock. A ground terminal on the frame of the

generator has been provided. For remote grounding,

connect a heavy gauge (4 mm) copper wire between

the generator ground terminal and a copper rod

driven into the ground.

The National Electrical Code requires that the frame

and external electrically conductive parts of this

generator be properly connected to an approved

earth ground. Local electrical codes may also require

proper grounding of the unit.

We strongly recommend that you consult with a

qualied electrician for grounding requirements in

your area.

7. STARTING THE ENGINE

7.1 Perform operating checklist.

7.2 Turn fuel valve to the “ ON “ position.

7.3 Turn off AC breaker protector.

7.4 Pull the choke valve switch to “ON” position.

OPEN CLOSE

11

A STEELFORT PRODUCT | STEELFORT.CO.NZ

CAUTION

Choke plate should be a different width due to

temperature change and other factors.

7.5 STARTING MODES

ELECTRIC START

Turn and keep the key to “START” position till the

engine is started. After the engine is started, release

the key to return to “RUN” position.

MANUAL START

Turn the switch to “RUN” position. Flick the switch

button to the open position, and then seize the

starter handle and slowly pull until there is a sense of

resistance, and quickly pull to start.

WARNING

KICKBACK

• Rapid retraction of the starter cord will pull

hand and arm towards the engine faster than

you can let go. Unintentional startup can result

in serious injury.

• If the electric starter fails to start the engine,

immediately turn off the starter. Do not attempt

to restart the engine before the failure of the

cause has been identied. Don’t restart the

engine by replacement of other storage battery

without authorisation.

CAUTION

• If the engine fails to start after 3 attempts and

or ames out after starting, inspect and ensure

that the generator has been placed on a at

horizontal surface and has enough engine oil.

• During starting, do not turn the starting switch

to “start” position for more than 5 seconds as

this could damage the motor and void warranty.

If the unit fails to start after the rst attempt,

restart only after 1O seconds has passed. After

the unit has been used for a period of time, if

the starting speed of the motor falls, please

replace the battery.

• During the operation of the unit, the battery

supplies power to the solenoid valve of the

carburetor. When the unit is turned off, make

sure that the starting switch is in “OFF”

position, otherwise the storage battery voltage

is reduced due to the operating solenoid valve

of the carburetor, impacting on starting for next

time.

• If the engine is equipped with an engine oil

alarm, the engine may not start if the engine

oil in the crankcase is lower than the minimum

required level. During the operation of the unit,

routinely inspect the engine oil levels. See

maintenance section for further details.

7.6 When the engine operates stably, pull the choke

valve to “CLOSE “ position.

7.7 The generator may be normally loaded.

WARNING

Connect the output terminal of the generator with

the electric equipment. Don’t start or stop the engine

when the electric equipment is in “ON” status.

VFT METER

(If applicable)

The VFT meter can be used for displaying voltage,

frequency(hertz), run time, and total run time as

applicable. (Display mode depends on the cong-

uration). The LCD displays each mode by pressing

the button below the display. The display meter

sets as either automatic switching mode or manual

operation mode. In the manual state, press MODE

BUTTON for mode switching; But in automatic mode,

OPEN CLOSE

12 A STEELFORT PRODUCT | STEELFORT.CO.NZ

MODE BUTTON is used for reset (operate cautiously

when necessary).

A. VOLTAGE (U):

Output Voltage of the generator.

B. FREQUENCY (F)

Output frequency in hertz

C. RUN TIME (R):

Run time of the generator for the current session.

NOTE: If display value is less than 100, the numeric

display will accurate to one decimal place. If the

operation time is 100 hour or greater, the display will

be “101”,”102” and so on.

D. TOTAL RUN TIME:

Total run time of the generator since rst operation

(display mode depends on the conguration).

1) The display value is accurate to one decimal

place; or

2) The display value shows as a integer.

8. CONNECT ELECTRICAL DEVICES

Inspect power cord for damage before using. There

is a hazard of electrical shock from crushing, cutting

or heat damage.

13

A STEELFORT PRODUCT | STEELFORT.CO.NZ

DANGER

ELECTRICAL SHOCK

• To reduce the risk of electrical shock, DO NOT

use electrical cords that are worn, frayed, bare

or otherwise damaged.

• DO NOT touch bare wires or receptacles.

• DO NOT handle generator or electrical cords

while standing in water, or barefoot, or while

hands or feet are wet.

1. Allow the engine to stabilise and warm up for a

few minutes after starting.

2. Make sure the electrical devices in “OFF” position

and the load current is not higher than the maximum

withstanding current of single socket.

CAUTION

If the current of a single load is higher than the max-

imum withstanding current of single socket, please

connect the load with the terminal.

3. Turn the AC breaker protector to “ON” position.

CAUTION

If connected devices overheat, turn them off and

disconnect them from generator.

9. BEARING CAPACITY

You must make sure your generator can supply

enough rated (running) and surge (starting) watts for

the electrical devices you plan to power at the same

time. Follow these simple steps to calculate the

running and starting watts that are necessary for

your purposes.

WARNING

• DO NOT overload the generator.

• Exceeding the generator’s capacity can

damage the generator and/or electrical devices

connected to it. Faults and damaged caused by

overloading may void warranty.

1. Select the electrical devices you will power at

the same time.

2. The amount of power you need to run all the

devices is the total rated (running) watts of

these items.

3. Identify how many surge (starting) watts you

will need. Surge wattage is the short burst of

power needed to start electric power tools and

or appliances. Because not all motors start at

the same time, total surge watts can

be estimated by adding only the electrical

device(s) with the highest additional surge

watts to the total rated watts from step 2.

WATTAGE REFERENCE CHART

14 A STEELFORT PRODUCT | STEELFORT.CO.NZ

WARNING

You must isolate the generator from electric utility by

opening the electrical system’s main circuit breaker

or main switch if the generator is used for backup

power. Failure to isolate the generator from the

power utility may result in injury or death to electric

utility workers and damage to the generator due to

the backfeed of electrical energy.

10. CHARGING THE BATTERY

(Applicable Types)

• Charge the battery by battery charging socket,

and keep the full charge of the battery for use

at any time.

• Charge the battery in dry environment.

WARNING

Batteries give off explosive hydrogen gas while

recharging. An explosive mixture will remain around

the battery for a long time after it has been charged.

The slightest spark can ignite the hydrogen and

cause an explosion, resulting in serious injury.

WARNING

• DO NOT allow smoking, open ame, sparks or

any other source of heat around a battery. Wear

protective goggles, rubber apron and rubber

gloves when working around a battery.

• Battery electrolyte uid is an extremely caustic

sulfuric acid solution that can cause severe

burns. If spill occurs ush area with clear water

immediately.

• To recharge Volt batteries, proceed as follows:

• Check uid level in all battery cells. If

necessary, add ONLY distilled water to cover

separators in battery cells.

• DO NOT use tap water.

• If the battery is equipped with vent caps, make

sure they are installed and are tight.

• If necessary, clean battery terminals.

• Connect charging circuit to power output panel

socket with marked “12-VOLTS D.C”.

• Connect battery charge cable clamp with red

handle to the positive(+) battery terminal.

• Connect battery charge cable clamp with black

handle to the negative(-) battery terminal

• Start engine. Let the engine run while battery

recharges.

• When battery has charged, shut down engine.

CAUTION

Use an automotive hydrometer to test battery state

of charge and condition. Follow the hydrometer

manufacturer’s instructions carefully. Generally, a

battery is considered to be at 100% state of charge

when specic gravity of its uid (as measured by

hydrometer) is 1.260 or higher.

11. STOPPING THE ENGINE

1. Remove all the load on generator

2. Turn-off AC breaker protector

Remove the plug of all electric equipment from the

generator panel.

15

A STEELFORT PRODUCT | STEELFORT.CO.NZ

WARNING

NEVER stop the engine with electrical devices con-

nected and with the connected devices turned “ON”.

3. Allow the generator run at no load for a few min-

utes to stabilise internal temperatures of the engine

and generator.

4. Turn off the ameout switch (turn the engine

switch to “OFF’’ position).

5. Turn fuel valve to ‘‘OFF’’ position.

12. LONG DISTANCE CONTROL

(Applicable Types)

STEP 1.

Installation of the generator is extremely simple.

Both the start-up and stop functions are built into the

generator itself and so it is not necessary to have an

external control box.

The generator can be started by a remote signal

through the normal open contact photovoltaic

installations.

It is imperative that the inverter charger is available

in order to do the startup process of the generator.

Below is an example of an off grid photovoltaic

installation.

Note: The following diagram is only indicative, a

general idea to understand the operation process.

Consult a professional and or installer to perform

correct installation.

STEP 2.

Understanding The General Operation.

The generator is designed to support photovoltaic

installations. The generator will provide power when

the solar energy is not enough.

This generator has been designed for an automatic

start and stop, commanded by an inverter/charger.

The inverter/charger can detect low battery levels

during operation. Similarly, the inverter charger will

send a stop signal to the generator if charging is

required. Not all inverter/chargers remotes from

generator connect with each other, consult your local

service dealer for more information.

230 V power input connection:

The automatic mode of the generator consumes very

little power when active.

16 A STEELFORT PRODUCT | STEELFORT.CO.NZ

This consumption is fed from the generator’s battery,

it is essential to connect a 230 V power input

otherwise the battery would be discharged within a

few hours.

This connection comes from the 230 V inverter

output and connects to the “input power 230 V” on

the generator’s control panel. This also gives power

to the battery and charger located in the generator

control panel, that is active; if the battery of the

generator has low charge it will be recharged through

this energy.

Note: Not feeding the 230 V power input means the

battery will go at within a few hours. This could lead

to further damage to the cells making it an unusable

battery.

Operation startup by remote contacts: the generator

consists of two normal open contacts. While the

inverter/charger keep the 2 contacts open, the

generator is off, as the gure below:

When the inverter/charger command the generator

startup, two contacts will join and the generator will

initiate the start up process. The generator keeps

running, while the contacts are joined.

When the contact splits again the generator will stop

and remain at rest until a next start.

STEP 3.

Understanding the Generator’s Startup & Stop

Process

1. The startup of the generator will begin a few

seconds after the outage of the power supply.

2. The system sends a signal to the choke closing

the air passage.

3. The system gives power to the starting motor

to start up the engine. If engine starts, the

power to the starting motor will immediately

stop to avoid any gear damage to the starting

motor.

The maximum working time of the starting motor

is 5 seconds. If the engine has not started after 5

seconds, the stating motor will be disconnected to

prevent overheating. If the engine has not started

after the rst attempt, a second attempt can be

performed after a few seconds, repeat process for a

maximum 5 attempts. If the generator does not start

automatically during the 5 attempts, the SIGNAL

lamp will blink, showing start failure and generator

pass to stop.

The engine has a temperature sensor, if the engine

is hot after recent operation, the choke signal will be

annulled.

NOTE: If you perform continuous auto start attempts

for I or 2 minutes it may cause malfunctions to the

temperature sensor. This may indicate that the tem-

perature levels will annul the choke even though the

engine temperature is not at the correct temperature

for a startup without choke assistance.

NOTE: In low temperature conditions, below 50 C

the engine will have much greater diculty to start

17

A STEELFORT PRODUCT | STEELFORT.CO.NZ

and may require more than 3 startup attempts. In

this case it would be necessary for an operator to

manually start with a key. We recommend installing

the equipment protected from intense cold to avoid

start up failures due to temperature.

NOTE: LawnMaster is not responsible in any way for

damages caused to products or equipment that may

arise from the lack of supply by a generator failure.

DANGER

This equipment is not designed to protect vital

equipment such as (life support equipment, extreme

safety equipment or other equipment that involves a

risk to persons or property in cases of lack of supply.

STEP 4.

Programming The Automatic Mode

The battery is extremely important for starting up in

automatic mode, before programming the equipment

check the battery is correct and that it is charged.

1 . Place the fuel valve switch to “ON” position.

2.Place the engine ignition key to “ON” position.

3. Push “SIGNAL MODE” switch to “ON” (auto mode).

The generator is ready for start by remote signal

when inverter/charger joins the 2-signal contacts.

After connect generator denitively with the inverter/

charger you can simulate a start/stop maneuver.

Join the signal contact and keep them connected,

generator will start the startup process according

point 9.3 of this manual.

After 5 minutes running you can separate the signal

contact, the generator stops and keep waiting for

next order.

18 A STEELFORT PRODUCT | STEELFORT.CO.NZ

Note 1: Applicable types (if available).

Note 2: Before each season and after then (whichever comes rst).

Note 3: Service more frequently under severe, dusty, dirty conditions.

Note 4: To be performed by knowledgeable, experienced owners or

the authorised dealer.

IV. MAINTENANCE

It is the operator’s responsibility to complete all

scheduled maintenance and or servicing in a timely

manner. Always correct any issues before operating

the generator. Follow all inspection and

maintenance recommendations that are listed in the

manual.

WARNING

Improper maintenance and or failure to correct

problems prior to operating the unit may cause the

unit to malfunction and result in property damage

and or serious personal injury. Improper maintenance

and servicing may void warranty.

DANGER

Accidental starts can cause serious personal injury.

Remove and ground the spark plug wire before

performing any service.

CAUTION

The lter element may contain PAHs, PAHs that

is harmful for your health. Please wear gloves for

protection during air lter maintenance.

1. MAINTENANCE SCHEDULE

Before servicing the generator, stop the

generator, disconnect all electric devices and battery

(if equipped) and allow the generator to cool down.

Follow the service intervals indicated in the chart

below. Service your generator more frequently when

operating in adverse conditions. Contact your local

Service Dealer if the generator requires maintenance.

19

A STEELFORT PRODUCT | STEELFORT.CO.NZ

2. GENERATOR MAINTENANCE

• Make certain that the generator is kept clean

and stored properly.

• Use a damp cloth to clean exterior surfaces of

the generator.

• Use an compressed air (25 PSI) to clear dirt

and debris from the generator.

• Inspect all air vents and cooling slots to ensure

that they are clean and unobstructed.

WARNING

• DO NOT use water to clean the generator. Water

can enter the generator through the cooling

slots and damage the generator windings.

• DO NOT modify the generator in any way.

• DO NOT tamper with governed speed.

Generator supplies correct rated frequency and

voltage when running at factory set.

• Tampering with the factory reset governor will

void your warranty

3. ENGINE MAINTENANCE

3.1 ENGINE OIL

LawnMaster 10W30 Oil (PP01020005) is

recommended. Other viscosities shown in the chart

may be used when the average temperature in your

area is within the indicated range. OIL MUST BE

PLACED IN ENGINE BEFORE STARTING.

Ambient Temperature

Oil capacity (rated):

See Parameters.

3.2 ADD OIL

1. Place the engine on a level surface.

2. Remove the dipstick and wipe it clean.

3. Add recommended oil to the upper limit.

CAUTION

3.4 OIL LEVEL CHECK

Reinstall dipstick into tube; rest on oil ll neck, DO

NOT thread cap into tube.

4. Fully tighten the dipstick.

5. Dispose of used oil at an approved waste manage-

ment facility.

3.5 CHANGE OIL

CAUTION

Change oil when the engine is warm from operation.

1. Place the engine on a level surface.

2. Clean area around dipstick and drain plug.

3. Remove oil dipstick.

20 A STEELFORT PRODUCT | STEELFORT.CO.NZ

4. Remove the oil drain plug and allow the oil to drain

completely.

5. Fully tighten the drain plug.

6. Add recommended oil to the upper limit (see add

oil instruction above).

7.Reinstall & fully tighten the dipstick.

8. Dispose of used oil at an approved waste manage-

ment facility.

WARNING

The engine is not lled with oil at the factory. Any

operation before it has been properly lled with the

recommended type and amount of oil may result in

engine damage and void your warranty.

3.6 AIR FILTERS

1. Loosen the lter x bolt and remove the cover

of the air lter.

2. Remove the foam lter element.

3. Wash in liquid detergent and warm water

4. Squeeze thoroughly dry in a clean cloth.

5. Saturate in clean engine oil.

6. Squeeze in a clean, absorbent cloth to remove

all excess oil.

7. Place the lter in the assembly.

8. Fasten the air lter cover with the x bolt, and

the mounting it back to the air lter body.

WARNING

DO NOT run the engine without the air lter as this

is dangerous can result in personal injury and or

damage.

3.7 SPARK PLUG

1. Clean any dirt from the spark plug cap and

spark plug base.

2. Remove the spark plug cap.

3. Using socket wrench to loose and remove the

spark plug.

4. Inspect the spark plug and spark plug washer,

if it’s damaged or worn, replace with new one.

Clean the spark plug with wire brush if reuse it.

5. Check spark plug gap. Carefully bend side

electrode to adjust the gap if necessary.

SPARK PLUG GAP: 0.6MM - 0.8MM

6. Carefully thread the plug into the engine by

hand.

7. After the spark plug is in position, use spark

plug wrench to tighten the plug.

SPARK PLUG TIGHTEN TORQUE: 15-20 N.M

8. Attach the spark plug wire to the plug.

WARNING

Only use the recommended spark plug or equivalent.

DO NOT use spark plugs that have improper heat

range.

3.8 SPARK ARRESTER

(Applicable types)

1. Allow the engine to cool completely before

servicing the spark arrester.

2. Remove the two bolts holding the cover plate

which retains the end of the spark arrester to

the muer.

3. Remove the spark arrester screen.

4. Carefully remove the carbon deposits from the

This manual suits for next models

26

Table of contents

Other LawnMaster Portable Generator manuals