LCI HF-320 a Series User manual

LOCHABER CORNWALL, INC.

LCI

Inverter

Sensorless Vector Inverter

TPSI

Series

TD-1

Transport

Drive

For all our customers'

easy use,

we made our inverter

even more compact,

easy maintenance, and

reduced noise.

Now, you have easier

access to high-function

and high-performance!

We actualized optimal

startup and acceleration

by building-in new current

vector computation and

Sumitomo Motor constant

in the standard type.

This inverter is ideal for

our gearmotor operation.

Series Name

HF-320αSeries

Input Source

2: 3-Phase 200V

4: 3-Phase 400V

S: 1-Phase 200V

Applicable Motor Output

A20: 0.2kW

A40: 0.4kW

A75: 0.75kW

1A5: 1.5kW

2A2: 2.2kW

3A7: 3.7kW

5A5: 5.5kW

7A5: 7.5kW

■Nomenclature example

Easy Access to High Performance !

■High Torque

■Built-in Noise Filter

■Easy-Maintenance and Long

Lifetime

■Compact

Corresponds to major

standards of the world

LCI FURNACES - TPSI

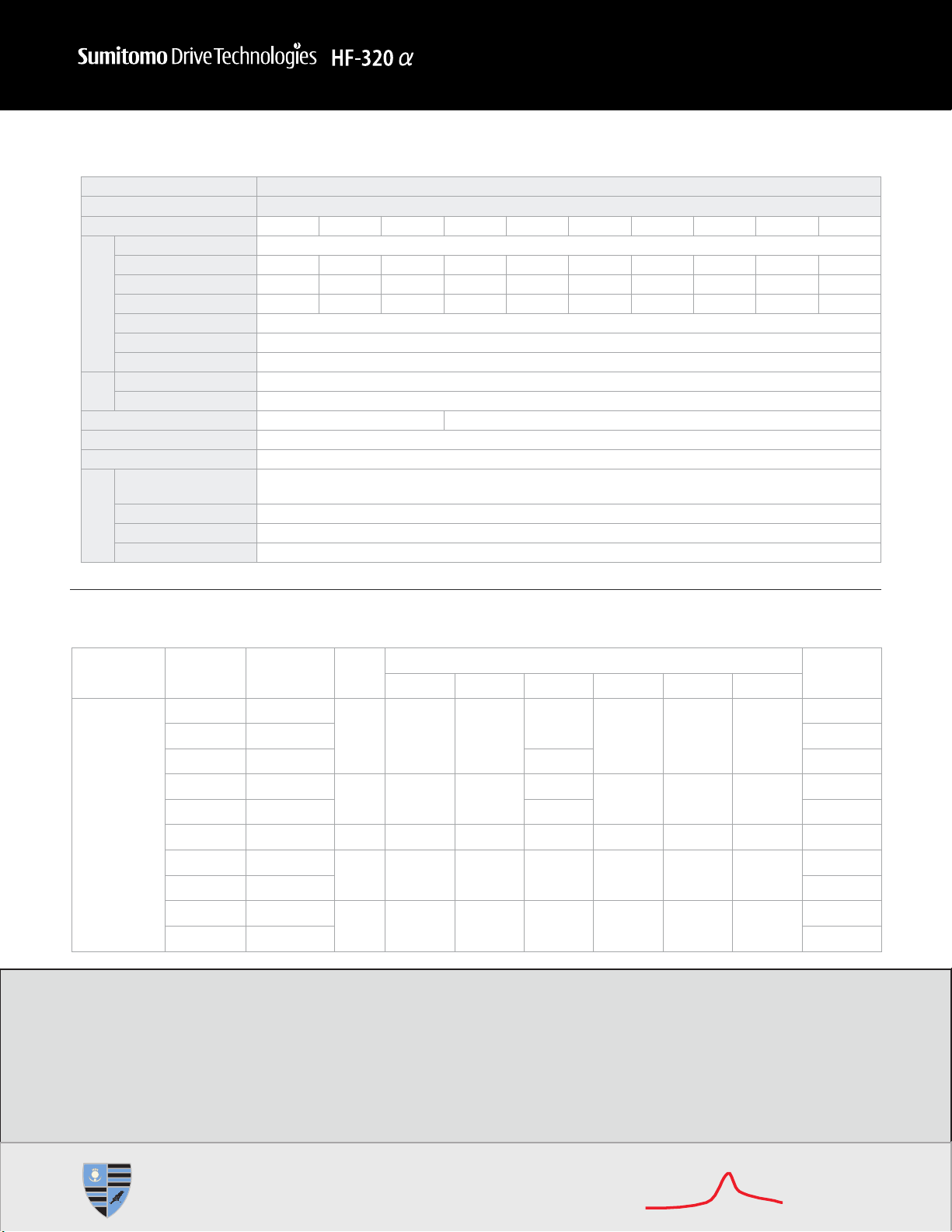

Item Specification

Input Voltage Class 3-Phase 200V

Motor HP (kW) 0.25 (0.2) 0.5 (0.4) 1 (0.75) 2 (1.5) 3 (2.2) 5 (3.7) 7.5 (5.5) 10 (7.5) 15 (11) 20 (15)

Rating

Type HF3212-

Motor Output A20 A40 A75 1A5 2A2 3A7 5A5 7A5 011 015

Capacity (kVA) [1] 0.6 1.3 1.8 3.1 4.2 6.7 10 13 21 25

Rated Output Current (A)[2] 1.6 (1.5) 3.3 (3.3) 5 (4.4) 8 (7.9) 11 (10) 17.5 (16.4) 27.5 (25) 33 (33) 54 (49) 66 (60)

Output Voltage [3] 3-phase 200V to 240V

Overload Current Rating 150% - 60 seconds, 200% - 0.5 seconds

Voltage Frequency 3-phase 200V to 240V - 50/60 Hz

Power

Supply

Allowable Fluctuation Voltage +10%, -15%[4], frequency ±5%

Protective Method IP20 enclosed type (JEM1030)

Cooling Method Self-cooling Forced air-cooled

Color Munsel 5Y-8/0.5

Built-in Filter RFI filter[5]

Environment

Atmosphere 2

Ambient Temperature -10°C to +50°C (above 40°C, remove the protective seal from the top of the inverter)

Storage Temperature -20°C to +65°C

Relative Humidity 20 to 93% (condensation free)

Notes:

[1] Capacity is calculated at 220V for the 200V class and at 440V for the 400V class.

[2] Indicates rated output current setting when the PWM carrier frequency (parameter F300) is 4kHz or less. When exceeding 4kHz, the rated output current setting is shown in parentheses

When the input power voltage of the 400V class model exceeds 480V, it is necessary to further reduce the setting. The default setting of the PWM carrier frequency is 12 kHz.

[3] Maximum output voltage is the same as the input voltage.

[4] ±10% when the inverver is used continuously (load of 100%).

[5] Built-in standard filter: Core and capacities; With RFI noise filter option: complies EN55011 Class AGroup 1 (Max. length of motor connecting cable 16.40 ft. or 5m) and Class B Group 1

(Max. length of motor connecting cable 3.28 ft. or 1m).

[6] in high-attenuation EMI filter: Complies EN55011 Class AGroup 1 (Max. length of motor connecting cable 16.40 ft. or 5m); With RFI noise filter option: complies EN55011 Class B

Group 1 (Max. length of motor connecting cable 65.62 ft. or 20m) and Class A Group 1(Max. length of motor connecting cable 164.04 FT OR 50 m.

Indoors; maximum altitude: 3,280.84 ft. (1000 m); not exposed to direct sunlight, corrosive or explosive gas,

vibration (less than 5.9m/s ) (10 to 55Hz)

Dimensions

Input Voltage Motor

HP (kW) Inverter Type Figure

Dimensions (mm) Approx.

Weight (kg)

W H D W1 H1 H2

3-phase 200V

0.25 (0.2) HF3212-A20

A 72 130 120 60 121.5 15

1.1

0.5 (0.4) HF3212-A40 1.2

1 (0.75) HF3212-A75 130 1.2

2 (1.5) HF3212-1A5 B 105 130 130 93 121.5 13 1.4

3 (2.2) HF3212-2A2 150 2.3

5 (3.7) HF3212-3A7 C 140 170 150 126 157 14 2.5

7.5 (5.5) HF3212-5A5 D 180 220 170 160 210 19.2 6.2

10 (7.5) HF3212-7A5 6.3

15 (11) HF3212-011 D*245 310 190 225 295 19.5 9.8

20 (15) HF3212-015 9.9

3-Phase 200V - 240V

Inverter

LOCHABER CORNWALL, INC.

LCI TPSI

Specifications

TD-3

■Sound Basic Functions

●With keypad and the frequency setting potentiometer on the

front panel, you can start operation easily and immediately.

●Every model has a regenerative braking circuit built-in, so only

an optional braking resistor needs to be connected if required.

●All three-phase and single-phase 200V models with a

capacity of 0.75kW or less are capable of self-cooling without

needing fans.

■Completely Noise-Proof

●An optional EMC plate can also be attached with a built-in

noise filter. This facilitates the wiring of shielded cables to

ground, and to the machine ground.

●If leakage current is a problem, disconnecting the grounding

capacitor can reduce it by simply pulling up a jumper switch

(Single-phase 200V and three-phase 400V models).

■

A Wide Variety of Input Terminal Functions

●Two analog input terminals can be used as logic input

terminals by changing parameter settings.

●If the two analog input terminals are switched over to logic

input terminals, up to eight contact input terminals can be

used at a same time.

●A function can be selected from among 65 functions and

assigned to each individual contact input terminal.

●With a slide switch, you can easily switch between sink logic

and source logic configurations.

●Power can be supplied from either the internal power supply

(24V) but also an external power supply (optional). In the

latter case, power is supplied through the PCS terminals.

■AGreat Variety of Output Terminals

●Three output terminals are provided: a relay contact output

terminal (1c), a relay contact terminal (1a) and an open

collector output terminal.

●The open collector output terminal (DRV-OM) completely

insulated from other terminals, which can also be used as a

pulse train output terminal.

●A function can be selected from 58 functions and assigned to

each individual output terminal.It is also possible to assign

two different functions to a single output terminal,

economizing on the use of terminals and cables.

●Analog output terminals can be be set for 0-10V, 0-1mA or 4-

20mA.

■Easy Selection and Installation

●Compact inverters with a wide range of capacities (0.2kW to

15kW) are available.

●Supporting a wide range of supply voltages:

240V class: 200V to 240V

500V class: 380V to 500V

Allowable fluctuations in voltage: +10%, -15%

●Operative in a wide range of ambient temperatures: -10°C to

+60°C (When the ambient temperature is 50°C and over, the

current needs to be reduced.)

■Dynamic Functions

●A dynamic energy saving mode specially designed for fan

motors provides substantial energy saving compared to

conventional modes.

●The energy saving effect can be checked easily by monitoring

integrated input and output kWh, in addition instantaneous

power.

●A dynamic quick deceleration control mode was added to

conventional deceleration modes achieving faster stopping

without using a braking resistor.

■AWide Choice of Monitor Menu Items

●A list of p to 20 parameters, including load current and torque

current, can be monitored during normal operation.

●Even if the inverter is tripped, monitoring of up to parameters

can continue until power is turned off.When power is turned

off, the last 10 parameters monitored at the occurrence of the

last four trips are retained.

●Up to 16 kinds of monitor menu items and up to 4 kinds of

outputs for adjustments can be assigned to the analog

terminals and the pulse train output terminals. Also,

adjustments can be made easily.

●A free-unit scaling function is provided so that various items,

such as the rotational speed and the line speed, can also be

displayed in addition to the operation frequency. Also, a bias

can be specified.

■Making Complicated Settings Easily

●With the automatic torque boost function, the motor can be

tuned easily for vector control. (The rated current, no-load

current and rated rotational speed of the motor need to be set

manually.)

●With the automatic acceleration/deceleration function, the

time can be set easily.

●With the automatic setting function, can be assigned easily to

input terminals on the terminal board.

●With the history function, a parameter that is used repeatedly

can be invoked and changed in one operation.

●Every HF-320Dinverter allows you to specify steps in which a

value changes each time a button on the operation panel is

pressed. For example, if you want to set the freguency by

steps of 10 Hz, this feature comes in very handy.

■Complete with Protective Functions

●All possible protective functions are provided to protect the

inverter and its peripheral devices.

●More than 30 kinds of information about causes of tripping and

more than 20 kinds of alarm information can be displayed.

●Every HF-320Dinverter has the function of protecting from

input/output open-phases detecting the breakage of analog

signal cables, and protecting from overcurrent, overvoltage

and overload.

■

Programmable for a Variety of Operations

●A PID control function is provided for every HF-320Dseries,

control devices are not required for PID control. It is also

possible to specify a control waiting time and to put out

command matching signals.

●Up to three different acceleration/deceleration times can be

set, so that the HF-320Dcan be put to a wide range of uses.

●A motor setting can be selected between two. It is possible to

select a base frequency, a voltage, an amount of torque

boost, a thermal protection level, a stall operation level, a V/F

pattern, and so on.

●The output frequency can be set within a range of up to 500Hz.

■

Complete with Communications Functions

●Terminal circuit boards are detachable and replaceable with a

large variety of optional circuit boards.

●An RS485 communications circuit board is optionally

available. It also suports Modbus RTU protocol.

●Optional software program enables you to set parameters

using a personal computer, you can easily check, read, edit,

write and save parameter settings.

●Using the block reading/writing function that was newly added to

communications functions, you can issue a command or

monitor the operating conditions more easily and more quickly.

●Communications circuit boards supporting DeviceNET,

LonWorks, and so on are on the drawing board.

Explanation of Function

3

TD-4

LCI FURNACES - TPSI

4

Before Using Our Inverters

■

Selecting the Capacity (Model) of the Inverter

Selection

●Capacity

Refer to the applicable motor capacities listed in the standard

specifications.

When driving a high-pole motor, special motor, or multiple

motors in parallel, select such an inverter that the sum of the

motor rated current multiplied by 1.05 to 1.1 is less than the

inverter's rated output current value.

●Acceleration/Deceleration Times

The actual acceleration and deceleration times of a motor

driven by an inverter are determined by the torque and

moment of inertia 2 of the load, and can be calculated by the

following equations.

The acceleration and deceleration times of an inverter can be

set individually. In any case, however, they should be set

longer than their respective values determined by the

following equations.

Acceleration time

ta = (JM+JL)u'N(sec)

9.56 u(TM+ TL)

Deceleration time

ta = (JM+JL)u'N(sec)

9.56 u(TB+ TL)

JM: Moment of inertia of motor (kg·m2)

JL:

Moment of inertia of load (kg

·

m

2

)

(converted

into value on motor shaft)

'N: Difference in rotating speed between before

and after acceleration or deceleration (min-1)

Conditions TL: Load torque (N·m)

TM:

Motor rated torque x 1.2-1.3 (N

·

m) [V/f control]

Motor rated torque x 1.5 (N·m) [Vector

operation control]

TB: Motor rated torque x 0.2 (N·m)

When a braking resistor or a braking resistor

unit is used:

Motor rated torque x 0.8-1.0 (N·m)

●Allowable Torque Characteristics

When a standard motor is combined with an inverter to

perform variable speed operation, the motor temperature

rises slightly higher than it normally does during commercial

power supply operation. This is because the inverter output

voltage has a sinusoidal (approximate) PWM waveform. In

addition, the cooling becomes less effective at low speed, so

the torque must be reduced according to the frequency.

When constant-torque operation must be performed at low speeds,

use an AF motor designed specifically for use with inverters.

Note 1. 100% of torque refers to the amount of torque that the motor

produces when it is running at a 60Hz-synchronized speed. The

starting torque is smaller in this case than that required when power

is supplied from a commercial power line. So, the characteristics of

the machine to be operated need to be taken into consideration.

Note 2. The maximum allowable torque at 50Hz can be calculated

approximately by multiplying the maximum allowable torque at a

base frequency of 60Hz by 0.8.

●Starting Characteristics

When a motor is driven by an inverter, its operation is

restricted by the inverter’s overload current rating, so the

starting characteristic is different from those obtained from

commercial power supply operation.

Although the starting torque is smaller with an inverter than

with the commercial power supply, a high starting torque can

be produced at low speeds by adjusting the V/f pattern torque

boost amount or by employing vector control. (200% in

sensorless control mode, though this rate varies with the

motor characteristics). When a larger starting torque is

necessary, select an inverter with a larger capacity and

examine the possibility of increasing the motor capacity.

■Harmonic Current and Influence to

Power Supply

●Harmonics are defined as sinusoidal waves that is multiple

freguency of commercial power (base frequency: 50Hz or

60Hz). Commercial power including harmonics has a

distorted waveform.

Some electrical and electronic devices produce distorted

waves in their rectifying and smoothing circuits on the input

side. Harmonics produced by a device influence other

electrical equipment and facilities in some cases (for example,

overheating of phase advancing capacitors and reactors).

■Measures for Suppressing Higher

Harmonics when Driving with Inverter

●Connecting a Reactor

Harmonic current leakage from the inverter may be suppressed

by connecting an input AC reactor (ACL) to the input side of

the inverter or DC reactor (DCL) to the DC section of the

inverter.

1. Input AC Reactor (ACL)

Used to improve the input power factor, reduce the harmonics,

and suppress external surge on the inverter power source

side.

2. DC Reactor (DCL)

DC reactor is more efficient on improving power factor for

inverter power source side. Use input AC reactor together,

for suppressing external surges.

Note: Refer to section on Peripheral Equipments, or Options for

measures on high frequency noise when using inverters.

0

0

20

40

60

80

100

120

140

160

180

200

10 20 30 40

Output Frequency (Hz)

Maximum torque

Maximum allowable continuous torque

50 60 70 80

Torque (%) (See Note 1.)

[An example of V/f

control at a base

frequency of 60 Hz]

TD-5

5

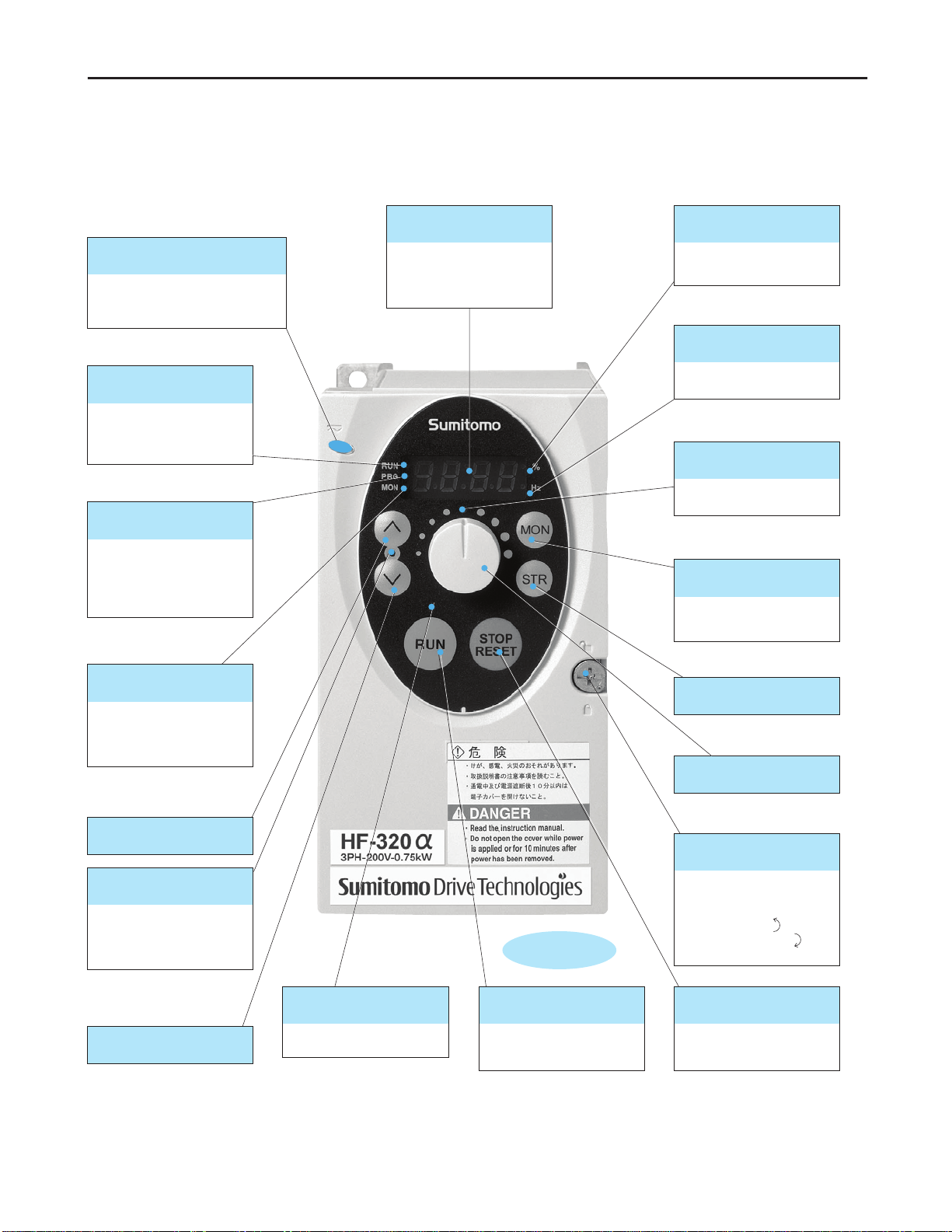

Operation

Full-scale

Displays the operation

frequency, a parameter, a

monitored item, the cause of

a failure, and so on.

■ Display

Lights when a numeric value

is displayed in %.

■ Percent (%) lamp

Lights when a numeric

value is displayed in Hz.

■ Hertz (Hz) lamp

Operation frequency can be

changed when lighted.

■

Built-in potentiometer lamp

Every pressing of this key while

the RUN key lamp is will cause

a slowdown stop.

■ STOP/RESET key

Displays operation

frequency, parameters, and

error causes.

■ Monitor (MON) key

Lights when an ON command

is issued but no frequency

signal is sent out. It blinks

when operation is started.

■ RUN lamp

Lights when the RUN key is

enabled.

■ RUN key lamp

Pressing this key while the RUN

key lamp is lighted starts

operation.

■ RUN key

Lights when the inverter is in

parameter setting mode. This

lamp blinks when the

parameter "AUH" or "Gr.U" is

selected.

■ PROGRAM lamp

Lights when the inverter is in

monitor mode. This lamp

blinks when a detailed past

trip record is displayed.

■ MONITOR lamp

■ Up key

■ Store (STR) key

■

Built-in potentiometer

■ Down key

Pressing up or down key

when this lamp is lighted

allows the setting of operation

frequency.

■ Up/Down key lamp Allows you to lock and unlock

the front panel easily.

Turn the screw 90°

counterclockwise to unlock,

or turn it 90° clockwise to lock

the front panel.

■

Front panel locking screw

Indicates that high voltage is still

present within the inverter. Do not

open the cover while this is lit.

■ CHARGE lamp

■Explanation of Operation Panel

TD-6

LCI FURNACES - TPSI

Operation

6

■How to Start and Stop

[Example of a CmOd setting procedure]

Key operated LED display Operation

0.0 Displays the operation frequency (operation stopped).

(When standard monitor display selection f710=0[Operation frequency])

auH Displays the first basic parameter [History (auH)].

CmOd Press either the or key to select "CmOd".

1Press STR key to display the parameter setting. (Default setting:1).

0Change the parameter to 0(terminal board) by pressing the key.

0CmOd Press the STR key to save the changed parameter. CmOd and the parameter set value

are displayed alternately.

■Start and Stop Using the Operation Panel Keys (CmOd=1)

Use the and keys on the operation panel to start and stop the motor.

: Motor starts.

: Motor stops.

■How to Set the Frequency

[Example of a fmOd setting procedure]

Key operated LED display Operation

0.0 Displays the operation frequency (operation stopped).

(When standard monitor display selection f710=0[Operation frequency])

auH Displays the first basic parameter [History (auH)].

fmOd Press either the or key to select "fmOd".

0Press STR key to display the parameter setting. (Default setting: 0).

3Change the parameter to 3(terminal board) by pressing the key.

3fmOd Press the STR key to save the changed parameter. fmOd and the parameter set value

are displayed alternately.

*Pressing the MON key twice returns the display to standard monitor mode (displaying operation frequency).

■

Setting the Frequency Using the Potentiometer on the Inverter Main Unit

(fmOd=0)

Set the frequency with the notches on the potentiometer.

Move clockwise for the higher frequencies.

The potentiometer has hysteresis. So the set value may slightly change when the inverter is turned off, and then turned back on.

STOP

RESET

RUN

STOP

RESET

RUN

MON

STR

STR

MON

STR

STR

TD-7

LCI FURNACES - TPSI

#

A?;0?90C3B7=)=7?A=@;8

1/3.?8BC2>>'

AB& 3B7=)=7?A=@;

;35AC@:A?+BC7:?88 1/3.?8BC2>>'

(33:=7?:BC&@A@9C,- ><2 ><* ><#4 6<4 2<2 1<# 4<4 #<4

1262/

(2> (*> (#4 6(4 2(2 1(# 4(4 #(4

"?3?7=A$C,'(-C%@ABC6 >< 6<1 6< 1<6 *<2 <# 6> 61

?AB0C@5A35AC7599B;A 6< 1<1 *< <> 66<> 6#<4 2#<4 11

,(-C%@ABC2 ,6<4- ,1<1- ,*<*- ,#<- ,6><>- ,6<*- ,24<>- ,11-

5A35AC@:A?+BC%@ABC1 1/3.?8BC2>>'CA@C2*>'

B9:@?0C7599B;AC9?A=;+ 64> />C8B7@;08C2>> /><4C8B7@;0

'@:A?+B/)9B5B;7$ 1/3.?8BC2>>'CA@C2*>'C/C4>>

(::@?:BC):57A5?A=@; '@:A?+BCC6> C/64 C%@ABC*C)9B5B;7$C4

9@AB7A=BC&BA.@0 2>C;7:@8B0CA$3BC,!6>1>-

"@@:=;+C&BA.@0 B:)/7@@:=;+ @97B0C?=9/7@@:B0

"@:@9 !5;8B:C4/><4

5=:A/=;C)=:AB9 ?8=7C)=:AB9C%@ABC4

1/3.?8BC*>>'

AB& 3B7=)=7?A=@;

;35AC@:A?+BC7:?88 1/3.?8BC*>>'

(33:=7?:BC&@A@9C,- ><* ><#4 6<4 2<2 *<> 4<4 #<4

126*/

(*> (#4 6(4 2(2 1(# 4(4 #(4

"?3?7=A$C,'(-C%@ABC6 6<6 6< 1<6 *<2 #<2 66 61

?AB0C@5A35AC7599B;A 6<4 2<4 *<6 4<4 <4 6*<1 6#

,(-C%@ABC2 ,6<4- ,2<6- ,1<#- ,4<>- ,<- ,61<>- ,6#-

5A35AC@:A?+BC%@ABC1 1/3.?8BC1>'CA@C4>>'

B9:@?0C7599B;AC9?A=;+ 64> />C8B7@;08C2>> /><4C8B7@;0

'@:A?+B/)9B5B;7$ 1/3.?8BC1>'CA@C4>>'C/C4>>

(::@?:BC):57A5?A=@; '@:A?+BCC6> C/64 C%@ABC*C)9B5B;7$C4

9@AB7A=BC&BA.@0 2>C;7:@8B0CA$3BC,!6>1>-

"@@:=;+C&BA.@0 @97B0C?=9/7@@:B0

"@:@9 !5;8B:C4/><4

5=:A/=;C)=:AB9 =+./?AAB;5?A=@;C!C)=:AB9C%@ABC

6/3.?8BC2>>'

AB& 3B7=)=7?A=@;

;35AC@:A?+BC7:?88 6/3.?8BC2>>'

(33:=7?:BC&@A@9C,- ><2 ><* ><#4 6<4 2<2

126/

(2> (*> (#4 6(4 2(2

"?3?7=A$C,'(-C%@ABC6 >< 6<1 6< 1<6 *<2

?AB0C@5A35AC7599B;A 6<4 1<1 *< <> 66<>

,(-C%@ABC2 ,6<4- ,1<1- ,*<*- ,#<- ,6><>-

5A35AC@:A?+BC%@ABC1 1/3.?8BC2>>'CA@C2*>'

B9:@?0C7599B;AC9?A=;+ 64> />C8B7@;08C2>> /><4C8B7@;0

'@:A?+B/)9B5B;7$ 1/3.?8BC2>>'CA@C2*>'C/C4>>

(::@?:BC):57A5?A=@; '@:A?+BCC6> C/64 C%@ABC*C)9B5B;7$C4

9@AB7A=BC&BA.@0 2>C;7:@8B0CA$3BC,!6>1>-

"@@:=;+C&BA.@0 B:)/7@@:=;+ @97B0C?=9/7@@:B0

"@:@9 !5;8B:C4/><4

5=:A/=;C)=:AB9 =+./?AAB;5?A=@;C!C)=:AB9C%@ABC

?A=;+

@B9

8533:$

?A=;+

@B9

8533:$

?A=;+

@B9

8533:$

%@ABC6< "?3?7=A$C=8C7?:75:?AB0C?AC22>'C)@9CA.BC2>>'C7:?88C?;0C?A

**>'C)@9CA.BC*>>'C7:?88<

%@ABC2< ;0=7?AB8C9?AB0C@5A35AC7599B;AC8BAA=;+C.B;CA.BC!C7?99=B9

)9B5B;7$C,3?9?&BAB9C1>>-C=8C*C@9C:B88<

.B;CB7BB0=;+C*CA.BC9?AB0C@5A35AC7599B;AC8BAA=;+C=8

=;0=7?AB0C=;CA.BC3?9B;A.B8=8<C.B;CA.BC=;35AC3@B9C@:A?+B

@)CA.BC*>>'C7:?88C&@0B:CB7BB08C*>'C=AC=8C;B7B88?9$CA@

)59A.B9C9B057BCA.BC8BAA=;+<C.BC0B)?5:AC8BAA=;+C@)CA.BC!

7?99=B9C9B5B;7$C=8C62<

%@ABC1< !?=&5&C@5A35AC@:A?+BC=8CA.BC8?&BC?8CA.BC=;35AC@:A?+B<

%@ABC*< 6> C.B;CA.BC=;B9AB9C=8C58B0C7@;A=;5@58:$C,:@?0C@)

6>> -<

%@ABC4< 5=:A/=;C8A?;0?90C)=:AB9C"@9BC?;0C7?3?7=A=B8

=A.CC;@=8BC)=:AB9C@3A=@;C"@&3:=B8C%44>66C":?88C(

9@53C6,!?<4&-C?;0C":?88CC9@53C6,!?<6&-

B;+A.C@)C&@A@9C7@;;B7A=;+C7?:B<

%@ABC< 5=:A/=;C.=+./?AAB;5?A=@;C!C)=:AB9

"@&3:=B8C%44>66C":?88C(C9@53C6,!?<4&-

=A.CC;@=8BC)=:AB9C@3A=@;C"@&3:=B8C%44>66C":?88C

9@53C6,!?<2>&-C?;0C":?88C(C9@53C6,!?<4>&-

B;+A.C@)C&@A@9C7@;;B7A=;+C7?:B<

$3BC@9&

$3BC@9&

$3BC@9&

TD-8

LCI FURNACES - TPSI

8

Common Specification

Item Specification

Control system Sinusoidal PWM control

Rated output voltage Adjustable within the range of 50 to 600V by correcting the supply voltage (not adjustable above the input voltage)

Output frequency range 0.5 to 500.0Hz, default setting: 0.5 to 80Hz, maximum frequency: 30 to 500Hz

Minimum setting steps of frequency

0.1Hz: operation panel setting, 0.2Hz: analog input (when the max. frequency is 100Hz).

Frequency accuracy Digital setting: within ±0.01% of the max. frequency (-10 to +60°C)

Analog setting: within ±0.5% of the max. frequency (25 C ±10°C)

Voltage/frequency characteristics

V/f constant, variable torque, automatic torque boost, vector control, automatic energy-saving, dynamic automatic energy-

saving control. Auto-tuning. Base frequency (25 - 500Hz) adjusting to 1 or 2, torque boost (0 - 30%) adjusting to 1 or 2,

adjusting frequency at start (0.5 - 10Hz)

Frequency setting signal Potentiometer on the front panel, external frequency potentiometer (connectable to a potentiometer with a rated impedance

of 1 - 10k ), 0 - 10Vdc (input impedance: VRF/VRF2=30k:), 4 - 20mAdc (Input impedance: 250 ).

Terminal board base frequency

The characteristic can be set arbitrarily by two-point setting. Possible to set individually for three functions: analog input

(VRF and VRF2) and communication command.

Frequency jump Three frequencies can be set. Setting of the jump frequency and the range.

Upper- and lower-limit frequencies

Upper-limit frequency: 0 to max. frequency, lower-limit frequency: 0 to upper-limit frequency

PWM carrier frequency Adjustable within a range of 2.0 to 16.0Hz (default: 4kHz).

PID control Setting of proportional gain, integral gain, differential gain and control wait time. Checking whether the amount of processing

amount and the amount of feedback agree.

Acceleration/deceleration time

Selectable from among acceleration/deceleration times 1, 2 or 3 (0.0 to 3200 sec.). Automatic acceleration/deceleration function.

S-pattern 1 or 2, and S-pattern value adjustable. Forced rapid deceleration and dynamic rapid deceleration function.

DC braking Braking start-up frequency: 0 to maximum frequency, braking rate: 0 to 100%, braking time: 0 to 20 seconds, emergency DC

braking, motor shaft fixing control

Dynamic braking Control and drive circuit is built in the inverter with the braking resistor outside (optional).

Input terminal function Possible to select from among 65 functions, such as forward/reverse run signal input, jog run signal input, operation base

signal input and reset signal input, to assign to 8 input terminals. Logic selectable between sink and source.

Output terminal functions

Possible to select from among 58 functions, such as upper/lower limit frequency signal output, low speed detection signal

output, specified speed reach signal output and failure signal output, to assign to FL relay output, open collector output and

RY output terminals.

Forward/reverse run

The RUN and STOP/RESET keys on the operation panel are used to start and stop operation, respectively. The switching between

forward run and reverse run can be done from one of the three control units: operation panel, terminal board and external control unit.

Jog run Jog mode, if selected, allows jog operation from the operation panel or the terminal board.

Preset speed operation Base frequency + 15-speed operation possible by changing the combination of 4 contacts on the terminal board.

Retry operation Capable of restarting automatically after a check of the main circuit elements in case the protective function is activated. 10

times (Max.) (selectable with a parameter)

Various prohibition settings

Possible to write-protect parameters and to prohibit the change of panel frequency settings and the use of operation panel

for operation, emergency stop or resetting.

Regenerative power ride-through control

Possible to keep the motor running using its regenerative energy in case of a momentary power failure. (Default: OFF)

Auto-restart operation In the event of a momentary power failure, the inverter reads the rotational speed of the coasting motor and outputs a

frequency appropriate to the rotational speed in order to restart the motor smoothly. This function can also be used when

switching to commercial power.

Drooping function When two or more inverters are used to operate a single load, this function prevents load from concentrating on one inverter

due to unbalance.

Override function The sum of two analog signals (VRF/VRF2) can be used as a frequency command value.

Failure detection signal 1c-contact output: (250Vac-0.5A-cos I= 0.4)

Protective function Stall prevention, current limitation, over-current, output short circuit, over-voltage, over-voltage limitation, undervoltage,

ground fault, power supply phase failure, output phase failure, overload protection by electronic thermal function, armature

over-current at start-up, load side over-current at start-up, over-torque, undercurrent, overheating, cumulative operation time,

life alarm, emergency stop, braking resistor over-current/overload, various pre-alarms

Electronic thermal characteristic

Switching between standard motor and constant-torque AF motor, switching between motors 1 and 2, setting of overload trip

time, adjustment of stall prevention levels 1 and 2, selection of overload stall

Reset function Function of resetting by closing contact 1a or by turning off power or the operation panel. This function is also used to save

and clear trip records.

Alarms Stall prevention, overvoltage, overload, under-voltage, setting error, retry in process, upper/lower limits

Causes of failures Over-current, overvoltage, overheating, short-circuit in load, ground fault, overload on inverter, over-current through arm at

start-up, over-current through load at start-up, CPU fault, EEPROM fault, RAM fault, ROM fault, communication error.

(Selectable: Over-current through braking resistor/overload, emergency stop, under-voltage, low voltage, over-torque, motor

overload, output open-phase)

Monitoring function Operation frequency, operation frequency command, forward/reverse run, output current, voltage in DC section, output

voltage, torque, torque current, load factor of inverter, integral load factor of PBR, input power, output power, information on

input terminals, information on output terminals, version of CPU1, version of CPU2, version of memory, PID feedback

amount, frequency command (after PID), integral input power, integral output power, rated current, causes of past trips 1

through 4, information on life alarm, cumulative operation time

Past trip monitoring function

Stores data on the past four trips: number of trips that occurred in succession, operation frequency, direction of rotation, load

current, input voltage, output voltage, information on input terminals, information on output terminals, and cumulative

operation time when each trip occurred.

Output for frequency meter

Analog output (1mAdc full-scale DC ammeter or 7.5Vdc full-scale DC voltmeter/rectifier type AC voltmeter, 4 to 20mA/0 to

20mA output)

4-digit 7-segments LED Frequency: inverter output frequency.

Alarm: stall alarm "C", overvoltage alarm "P", overload alarm "L", overheat alarm "H".

Status: inverter status (frequency, cause of activation of protective function, input/output voltage, output current, etc.) and

parameter settings.

Free-unit display: arbitrary unit (e.g. rotating speed) corresponding to output frequency.

Indicator Lamps indicating the inverter status by lighting, such as RUN lamp, MON lamp, PRG lamp, % lamp, Hz lamp, frequency

setting potentiometer lamp, UP/DOWN key lamp and RUN key lamp. The charge lamp indicates that the main circuit

capacitors are electrically charged.

Use environments

Indoor, altitude: 1000m (Max.), not exposed to direct sunlight, corrosive gas, explosive gas / vibration (less than 5.9m/s2) (10 to 55Hz)

Ambient temperature -10 to +50°C Note 1

Storage temperature -25 to +65°C

Relative humidity 20 to 93% (free from condensation and vapor).

Note 1. Above 40°C : Remove the protective seal from the top of the inverter.

Environments

Display function Protective function Operation specifications Principal control functions

(programmable)

(programmable)

9

Protective Functions

Error code Problem Possible causes

Overcurrent during

acceleration

Overcurrent flowing

in element during

acceleration

Overcurrent during

deceleration

Overcurrent flowing

in element during

decelearion

Overcurrent during

constant speed operation

Overcurrent flowing in

element during operation

Ground fault trip

Arm overcurrent at

start-up(for 11 and

15 kW models only)

Overcurrent (An

overcurrent on the

load side at start-up)

Arm overcurrent at

start-up

Input phase failure

Output phase failure

Overvoltage during

acceleration

Overvoltage during

deceleration

Overvoltage during

constant-speed

operation

Inverter overload

Motor overload

Error code Problem Possible causes

Dynamic braking

resistoroverload trip

Over-torque trip

Overheat

External thermal trip

Emergency stop

EEPROM fault 1

EEPROM fault 2

EEPROM fault 3

Main unit RAM fault

Main unit ROM fault

CPU fault 1

Remote control

error

Current detector

fault

Optional circuit

board format error

Low-current

operation

Trip

Undervoltage

trip(main circuit)

Ground fault trip

Auto-tuning error

Invertertype error

Brea in analog

signal cable

CPU

communications

error

Excessive torque

boosted

CPU fault 2

OL 1

OC IP

OC2

OC2P

OC3

OC3P

OC1P

OC2P

OC3P

OCL

OCA

*

EPHI

*

EPHO

OPI

OP2

OP3

OL1

OL2

OLr

*

Ot

OH

OH2

E

EEP1

EEP2

EEP3

Err2

Err3

Err4

Err5

Err7

Err8

*

UC

*

UPI

EF2

etnI

etyp

*

E-18

E-19

e-20

e-21

· The acceleration time acc is too short.

· The V/F setting is improper.

· A restart signal is imput to the rotating

motor after a momentary stop, etc.

· A special motor (e.g. motor with a small

impedance) is used.

· The deceleration time dec is too short.

· The load fluctuates abruptly.

· The load is in an abnormal condition.

· A current leaked from an output cable or

the motor to ground.

· A main circuit elements is defective.

· The insulation of the output main circuit or

motor is defective.

· The motor has too small impedance.

· A 11 or 15 kW model was started,

although a current is leaked from an

output cable or the motor to ground.

· A main circuit elements is defective.

· A phase failure occured in the input line of

the main circuit.

· The capacitor in the main circuit lacks

capacitance.

· A phase failure occurred in the output line

of the main circuit.

· The imput voltage fluctuates abnormally.

1. The power supply has a capacity of

200kVA or more.

2. A power factor improvement capacitor

is opened or closed.

3.

A system using a thyrister is connected

to the same power distribution line.

· A restart signal is input to the rotating

motor after a momentary stop, etc.

· The deceleration time dec is too short.

(Regenerative energy is too large.)

·f304 (dynamic braking resistor) is off.

·f305 (overvoltage limit operation) is off.

· The input voltage fluctuates abnormally.

1. The power supply has a capacity of

200kVA or more.

2. A power factor improvement capacitor

is opened and closed.

3. A system using a thyrister is connected

to the same power distribution line.

· The input voltage fluctuates abnormally.

1. The power supply has a capacity of

200kVA or more.

2. A power factor improvement capacitor

is opened or closed.

3. A system using a thyrister is connected

to the same power distribution line.

· The motor is in a regenerative state

because the load causes the motor to run

at a frequency higher than the inverter

output frequency.

· The acceleration time ACC is too short.

· The DC braking amout is too large.

· The V/F setting is improper.

· A restart signal is input to the rotating

motor after a momentary stop, etc.

· The load is too large.

· The V/F setting is improper.

· The motor is locked up.

· Low·speed operation is performed

continuously.

· An excessive load is applied to the motor

during operation.

· The deceleration time is too short.

· Dynamic braking is too large.

· Over-torque reaches to a detection level

during operation.

· The cooling fan does not rotate.

· The ambient temperature is too high.

· The vent is blocked up.

· A heat generating device is installed close

to the inverter.

· The thermistor in the unit is broken.

· An external thermal trip is input.

· During automatic operation or remote

operation, a stop command is entered

from the operation panel or a remote input

device.

· A data writing error occurs.

· Power supply is cut off during typ

operation and data writing is aborted.

· A data reading error occurred.

· The control RAM is defective.

· The control ROM is defective.

· The control CPU is defective.

· An error arises during remote operation.

· The current detector is defective.

· An optional circuit board in a different

format is installed.

· The output current decreased to a low-

current detection level during operation.

· The input voltage (in the main circuit) is

too low.

· A ground fault occurs in the output cable

or the motor.

· Check the motor parameter f401 to f494.

· The motor with the capacity of 2 classes

or less than the inverter is used.

· The output cable is too thin.

· The motor is rotating.

· The inverter is used for loads other than

those of three-phase induction motors.

· Circuit board is changed. (Or main

circuit/drive circuit board)

· The signal input via VRF is below the

analog sinal detectio level set with f633.

· A communications error occurs between

control CPUs.

· The torque boost parameter vb is set too

high.

· The motor has too small impedance.

· The control CPU is defective.

TD-10

LCI FURNACES - TPSI

10

Terminal Functions

■Main Circuit Teminal Functions

Terminals symbol Terminal function

Grounding terminal for connecting inverter. There are 3 terminals in total. 2 terminals in the terminal board, 1

terminal in the cooling fin.

200V class: single-phase 200~240V-50/60Hz *Single-phase input: R/L1 and S/L2 terminals

R/L1, S/L2, T/L3 3-phase 200~240V-50/60Hz

400V class: 3-phase 380~500V-50/60Hz

U/T1, V/T2, W/T3 Connect to a (three-phase induction) motor.

P(+), PR Connect to braking resistors. Change parameters f304,f305,f309, if necessary.

N(-) This is a negative potential terminal in the internal DC main circuit. DC common power can be input across

the P(+) terminals (positive potential).

P1, P(+) Terminals for connecting a DC reactor (DCL: optional external device). Shorted by a short bar when shipped

from the factory. Before installing DCL, remove the short bar.

■Control Circuit Terminal Functions

Multifunction programmable

contact input

Shorting across FR-COM causes forward rotation; open

causes slowdown and stop.

Shorting across FR-COM causes reverce rotation; open

causes slowdown and stop.

Shorting across RST-COM causes a held reset when the

inverter protector function is operating. Note that when

the inverter is operating normally, it will not operate even

if there is a short across RST-COM.

Shorting across DFL-COM causes preset speed operation.

Shorting across DFM-COM causes preset speed operation.

Shorting across DFH-COM causes preset speed opera

tion.

Terminal

symbol

FR

RR

RST

DFL

DFM

DFH

PCS External 24Vdc power input

Control circuit's equipotential terminal (sink logic).3 common

terminals for input/output.

24Vdc (Insulation resistance: 50Vdc)

10Vdc (permissible load current: 10mAdc)

10Vdc (internal impedance: 30k:)

4~20mA (Internal impedance: 250:)

10Vdc (internal impedance: 30k:)

1mA full-scale DC ammeter or 7.5Vdc

1mA full-scale

DC voltmeter

0-20mA (4-20mA) full-scale

DC ammeter

24Vdc - 100mA

Open collector output:

24Vdc - 50mA

Pulse train output

10mA or more

250Vac - 1A: at resistance load

30Vdc - 0.5A, 250Vac - 0.5A

(cosI= 0.4)

Dry contact input

24Vdc - 5mA or less

*Sink/Source/PCS

selectable using SW

COM

Power output for analog input setting.

+V Multifunction programmable analog input. Standard default

setting: 0-10Vdc input and 0-60Hz frequency. The function can

be changed to 4-20 mAdc (0-20 mA) current input by flipping

the VRF slide switch to the I position.

Multifunction programmable analog input. Standard default

setting: 0-10Vdc input and 0-50Hz (50Hz setting) or 0-60Hz

(60Hz setting) frequency.

Multifunction programmable analog output.

Standard default setting: output freguency. Connect a 1mAdc

full-scale ammeter or 7.5Vdc (10Vdc)-1mA full-scale voltmeter.

The function can be changed to 0-20mAdc (4-20mA) current

output by flipping the FRQ slide switch to the I position.

VRF

VRF2

FRQ

When the source logic is used, a common terminal 24Vdc is

connected.

P24V

Multifunction programmable open collector output. Standard

default settings detect and output speed reach signal output

frequencies.

The OM terminal is an isoelectric output terminal. It is insulated

from the COM terminal.

These terminals can also be used as multifunction

programmable pulse train output terminals.

DRV

OM

Multifunction programmable relay contact output.

Contact ratings: 250Vac - 2A (cos = 1), 30Vdc - 1A, 250Vac -

1A (cos = 0.4).

Standard default settings detect and output low-speed signal

output frequencies.

RC

RY

250Vac - 1A: at resistance load

30Vdc - 0.5A, 250Vac - 0.5A

(cosI= 0.4)

Multifunction programmable relay contact output.

Contact ratings: 250Vac-1A (cos = 1), 30Vdc-0.5A, 250Vac-

0.5A (cos = 0.4).

Detects the opertion of the inverter’s protection function.

Contact across FA-FC is closed and FB-FC is opened during

protection function operation.

FA

FB

FC

Note 1

Note 1

Note 2

Note 2

Electrical specifications Wire sizeFunction

Solid wire : 0.3 to 1.5 (mm2)

Stranded wire :

0.3 to 1.5 (mm2)

(AWG22 to 16)

Sheath strip length : 6 (mm)

Screwdriver:

Small-sized flat-blade screwdriver

Blade thickness:

0.4 mm or less

Blade width: 2.5 mm or less

Note 1: By changing parameter setting, this terminal can also be used as a multifunction programmable contact input terminal.

When the inverter is used in a sink logic configuration, a resistor (4.7k at 0.5W) should be inserted between the P24 and VRF/VRF2 terminals.

Also, the slide switch for the VRF terminal needs to be turned to the V position.

Note 2: Multifunction output terminals to which two different functions can be assigned.

TD-11

11

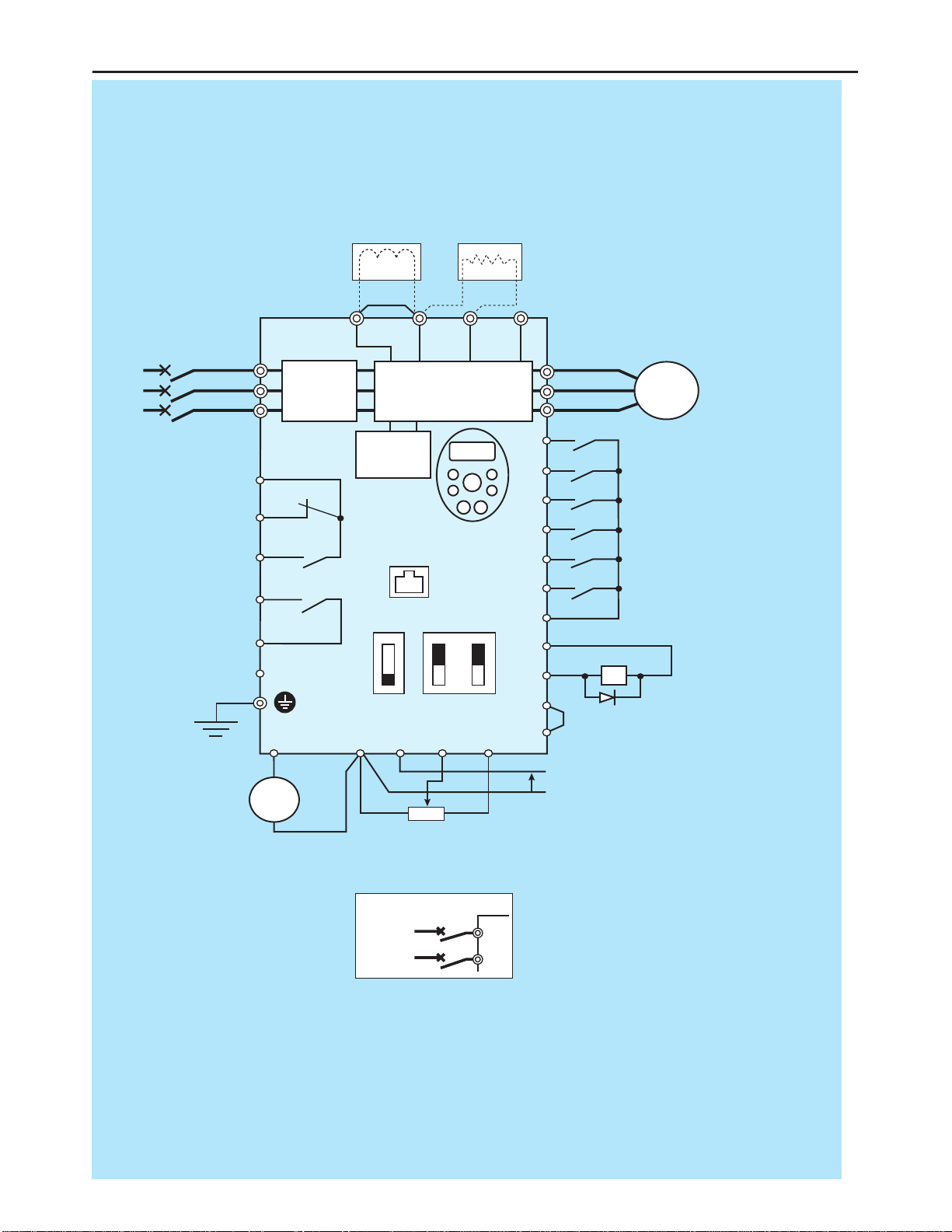

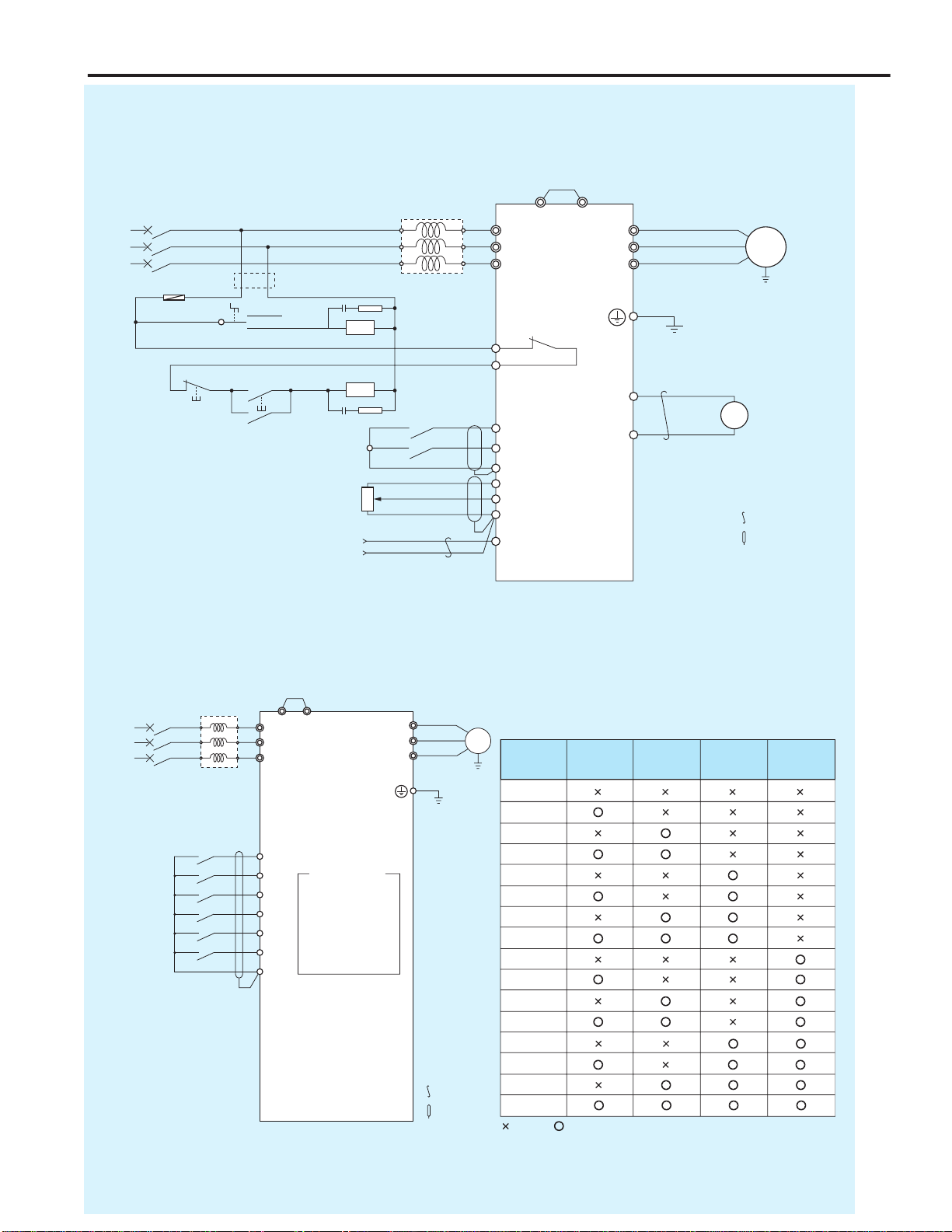

Standard Connection Diagram

MCCB

*1

R/L1

S/L2

T/L3

U/T1

V/T2

W/T3 I M

FC

FB

FA

RY

PCS

RC

Motor

FR

RR

RST

DFL

DFM

DFH

COM

P24V

DRV

OM

COM

FRQ

PCS

COM VRF VRF2 +V

++

−

−

P1 P(+) PR N(-)

Voltage signal: 0-10V

(Current signal: 4-20mA)

External potentiometer (1-10kΩ)

(or input voltage signal across VRF2-COM terminals: 0-10V)

Control

circuit

Operation

panel

Fault detection relay

Ry

HF-320α

Frequency

meter

(ammeter)

Main circuit

Noise

filter

DC reactor (DCL)

*2 (option)

Connector for

common serial

communications

Foward

Reverse

Reset

Preset-speed 1

Preset-speed 2

Preset-speed 3

Common

Braking resistor (option)

MCCB (2P)

R/L1

S/L2

Power supply

1φ200~240V

-50/60HZ

Speed reach

signal output

I ISINK

SW1

SOURCE

FRQ

VVRF

V

Main circuit power supply

200V class: 3-phase

200-240V -50/60Hz

400V class: 3-phase

380-500V -50/60Hz

*3

Low-speed

signal output

*1: The T/L3 terminal not providedfor signal-

phase models.

Use the R/L1 and S/L2 terminal as input

terminals.

*2: The inverter came with the P1 and the P(+)

terminals shorted by means of a shoeting

bar.

Before installing the DC reactor (DCL),

remove the bar.

*3: When using the DRV output terminal in sink

logic mode, short-circuit the OM and COM

terminals.

■Sink (Negative) Logic: Common = COM

TD-12

LCI FURNACES - TPSI

12

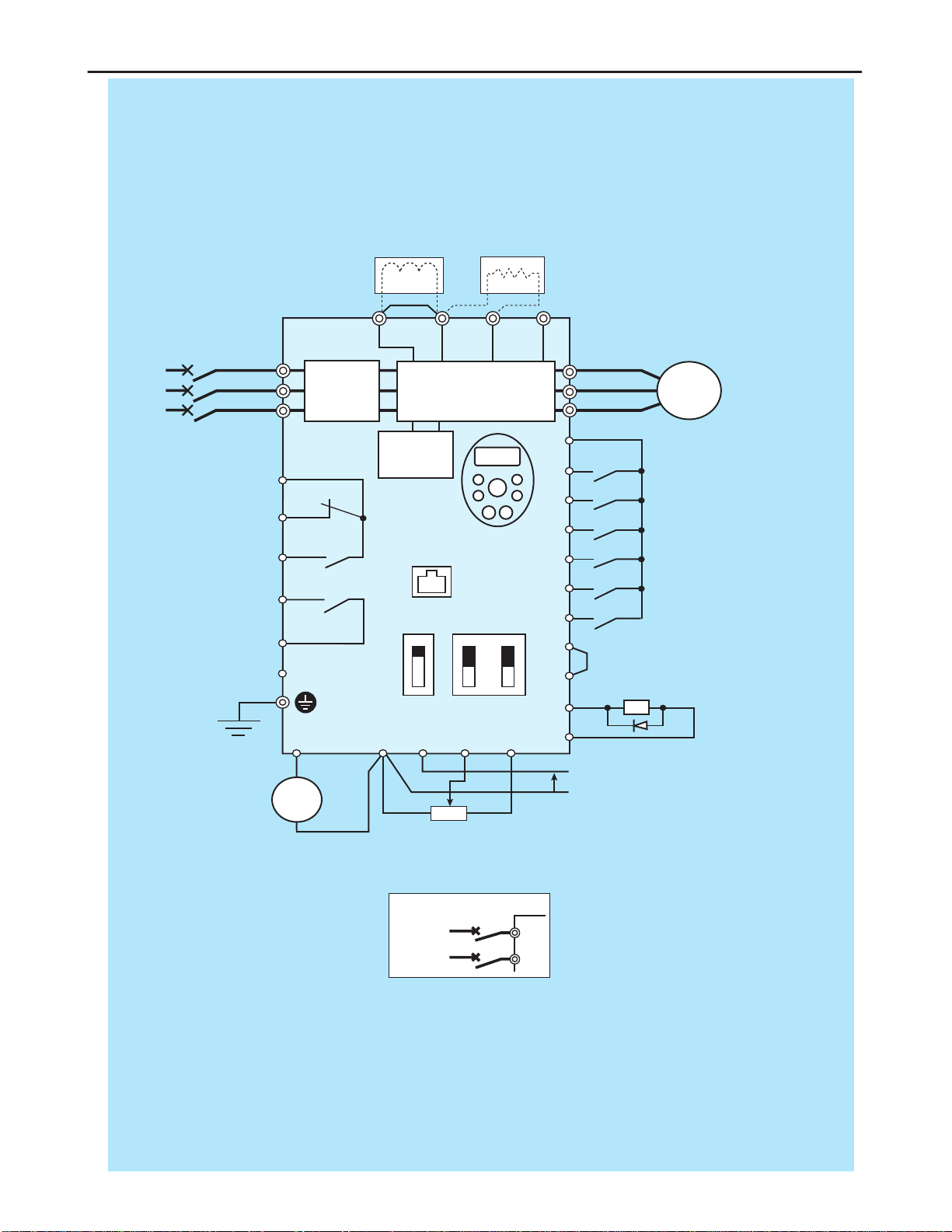

Standard Connection Diagram

MCCB

*1

R/L1

S/L2

T/L3

U/T1

V/T2

W/T3 I M

FC

FB

FA

RY

RC

P24V

FR

RR

RST

DFL

DFM

DFH

P24V

DRV

OM

COM

P1

MCCB(2P)

R/L1

S/L2

FRQ COM VRF VRF2 +V

PCS

P(+) PR N(-)

I ISINK

SW1

SOURCE

FRQ

VVRF

V

*3

Ry

PCS

Motor

++

−

−Voltage signal: 0-10V

(Current signal: 4-20mA)

External potentiometer (1-10kΩ)

(or input voltage signal across VRF2-COM terminals: 0-10V)

Control

circuit

Operation

panel

Fault detection relay HF-320α

Frequency

meter

(ammeter)

Main circuit

Noise

filter

DC reactor (DCL)

*2 (option)

Connector for

common serial

communications

Foward

Reverse

Reset

Preset-speed 1

Preset-speed 2

Preset-speed 3

Braking resistor (option)

Power supply

1φ200~240V

-50/60HZ

Speed reach

signal output

Main circuit power supply

200V class: 3-phase

200-240V -50/60Hz

400V class: 3-phase

380-500V -50/60Hz

Low-speed

signal output

*1: The T/L3 terminal not providedfor signal-

phase models.

Use the R/L1 and S/L2 terminal as input

terminals.

*2: The inverter came with the P1 and the P(+)

terminals shorted by means of a shoeting

bar.

Before installing the DC reactor (DCL),

remove the bar.

*3: When using the OM output terminal in

source logic mode, short-circuit the P24V

and DRV terminals.

■Source (Positive) Logic: Common = P24

TD-13

LCI FURNACES - TPSI

13

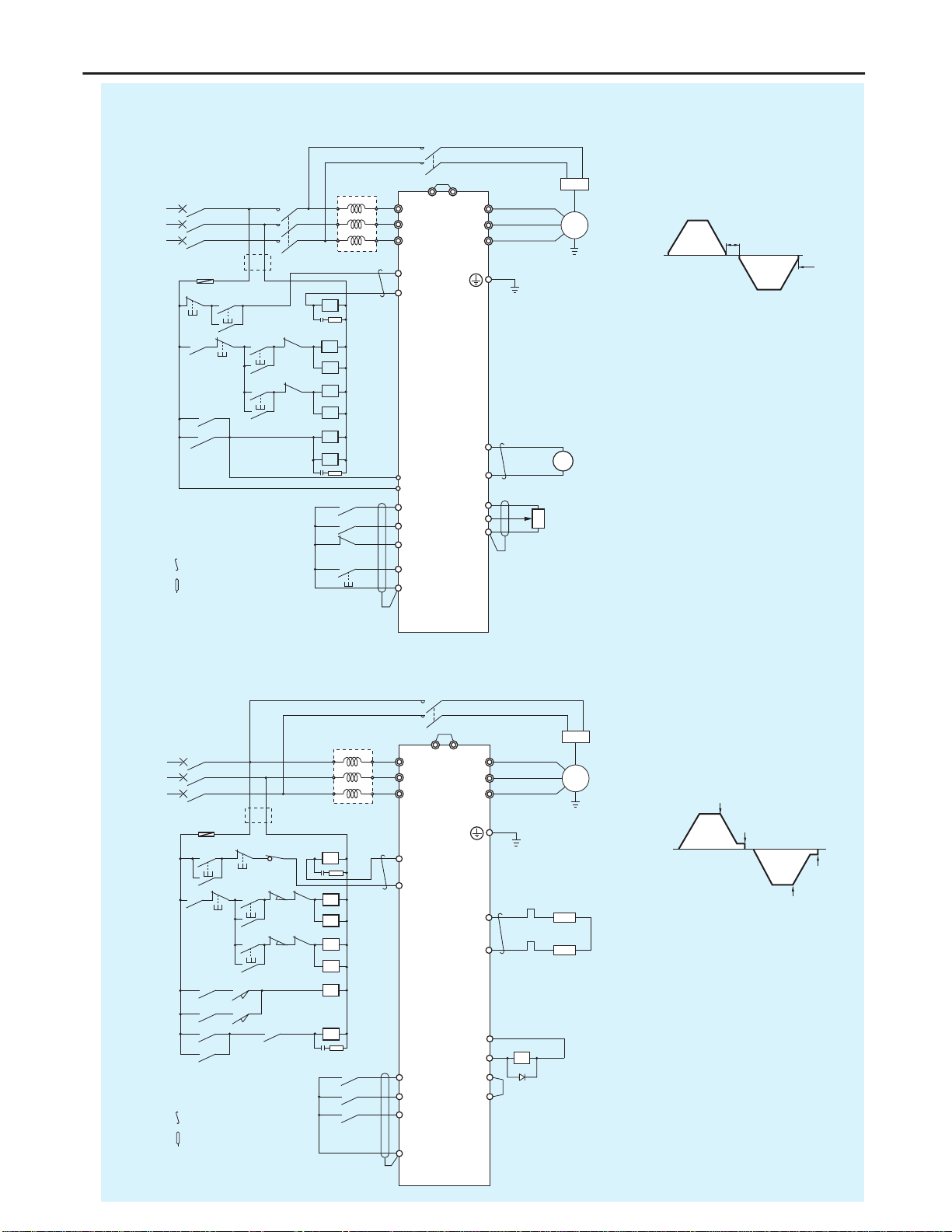

Applied Connection Diagram

P P1

ACL

U

V

W

X

Y

Z

MCCB

Tx

FU

RN

Run

Stop

RN

RN

AU

AU FB

FC

COM

+V

COM

VRF

+

-

+

FM

−

FRQ

COM

IM

HF-320α

R/L1

S/L2

T/L3

U/T1

V/T2

W/T3

(+)

Note 4

Manual

(Speed setting unit)

Auto (Current signal)

FR Note 1

2DF Note 3

VRF Note 2

Note 1: Set parameter CMOD to “0: Terminal board”

Note 2: Set parameter FMOD to “2: VRF2.” Set Parameter F201 to "1: VRF." and set switch VRF on 1 side.

Note 3: Set parameter F114 to “38: Frequency command forced awitching to F207”

Note 4: Install a step-down transformer when the power is 400 V-class.

Speed setting unit

1kΩ

Current signal

DC4–20mA

Frequency counter

10V F.S.

Ground

TH (Note)

: Twisted wire

: Shielded wire

Power

■Operation by Current Signal (4-20 mADC)

When terminal DFL is used as a current/voltage signal (speed setting unit) changeover signal

input.

■Multispeed Operation (16-Step Speed)

MCB P1

P

IM

FR

RR

DFL

DFM

DFH

RST

COM

F114=6

CMOD=0

F115=7

F116=8

F113=9

FC

Sr2

Sr1

Sr3

Sr4

Sr5

Sr6

Sr7

F287

F288

F289

F290

F291

F292

F293

F294

U X

Y

Z

V

W

HF-320α

R/L1

S/L2

T/L3

U/T1

V/T2

W/T3

(+)

Power

Forward rotation

Multi-stage speed 1

Multi-stage speed 2

Multi-stage speed 3

Multi-stage speed 4

TH

: Twisted wire

: Shielded wire

Multi-stage speed 1

Parameter setting

Multi-stage speed 2

Multi-stage speed 3

Multi-stage speed 4

Frequency

setting Multi-stage

speed

2

Multi-stage

speed

1

Multi-stage

speed

3

Multi-stage

speed

4

Frequency setting by external signal

(: Open, : Closed)

TD-14

LCI FURNACES - TPSI

MCCB ACL

BR

R/L1

X

U

YV

Z

W

S/L2

T/L3

FB

FC

U/T1

V/T2 IM

Br

W/T3

OFF

FU

ON

MC R

F

R

F

FX FR

RR

DFL

RST

COM

RX

BX

F

R

MC

F

FX

R

RX

BX

BR

MC

MC

+

FM

FRQ

COM −

+V

VRF

COM

HF-320α

PP1

(+)

RC

RY

Power

Preparation

for operation

Stop

Normal

rotation

Reverse

rotation

Note 2

Note 3

Reset

Frequency

counter

10V F.S.

Tx

Note 1

Speed setter

1kΩ

Note 1: When the power supply is a 400

V class, install a step-down

transformer.

Note 2: Set parameter F114 to 54.

Note 3: Set parameter F130 to 14.

: Twisted wire

: Shielded wire

Brake

Brake

Normal

rotation

Reverse

rotation

Operation pattern

MCCB ACL

BR

XU

YV

Z

W

FB

FC

IM

Br

P

PR

FU

R

LS2

LS4

F

R

F

FX FR

RR

DFL

COM

RX

DF

FLS1

R

F

R

LS3

F

FX

R

RX

DF

BR

Tx

LS1

HF-320α

LS2

LS1, LS3

LS3

LS4

P P1

THR

MC

MC

ON

MC

OFF THR

UPF

R/L1

S/L2

T/L3

U/T1

V/T2

W/T3

(+)

(+)

Power

Note 1

Stop

Normal

rotation

Reverse

rotation

Note 2

Note 4

Tx

Note 3

: Twisted wire

: Shielded wire

Normal

rotation

Normal

rotation

Operation pattern

Braking resistor

The limit switch is a

holding type.

Preparation

for operation

Note 1: Use inflammable cable for

braking resistor wiring.

Note 2: Parameter Sr1 is for

slow-speed frequency setting

and FC is for high-speed

setting.

Note 3: When the power supply is a

400 V class, install a

step-down transformer.

Note 4: Set parameter F131 to 4 and

adjust the braking timing by

F100 .Parameters F100

should be set at approx. 2 Hz

usually.

P24V

OM

DRV

COM

UPF

TD-15

15

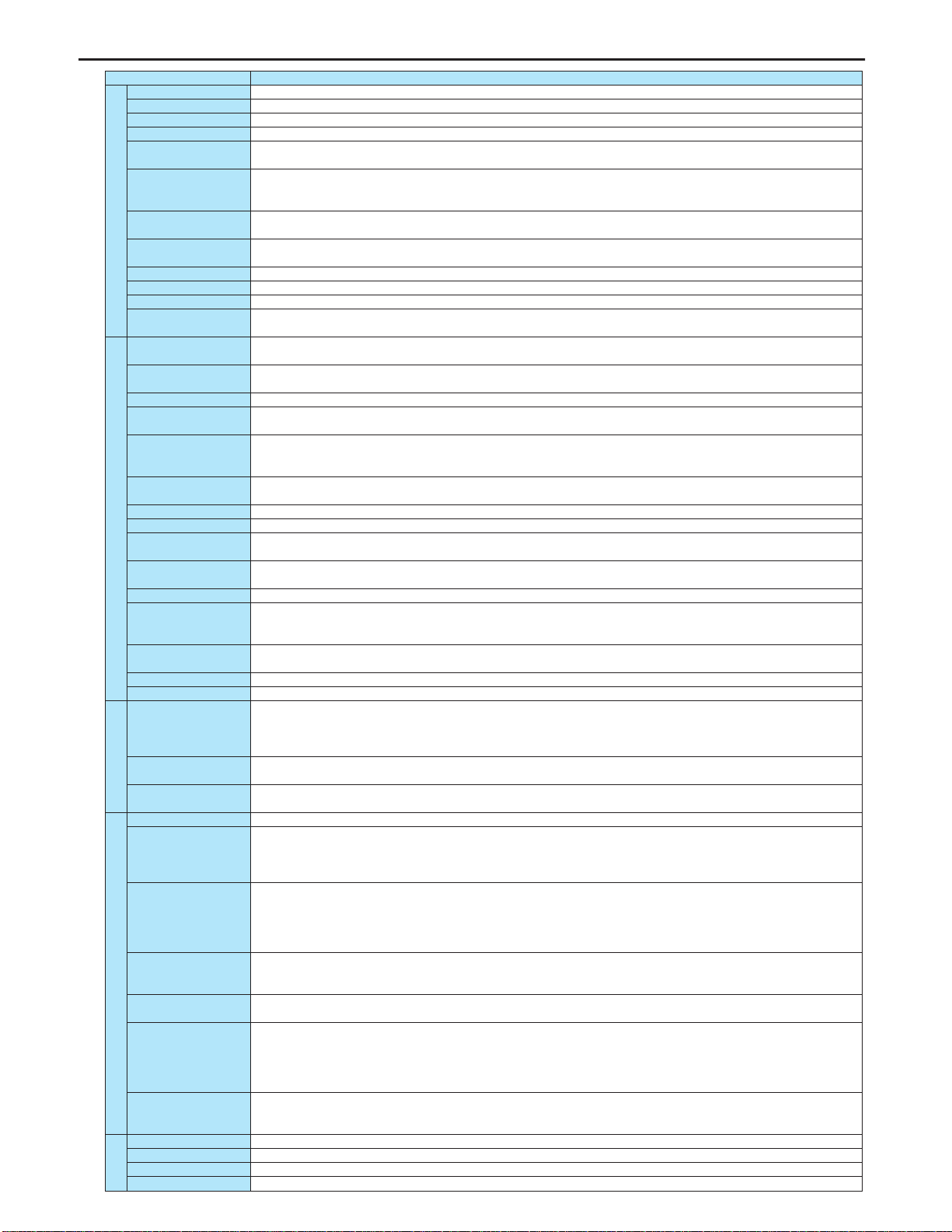

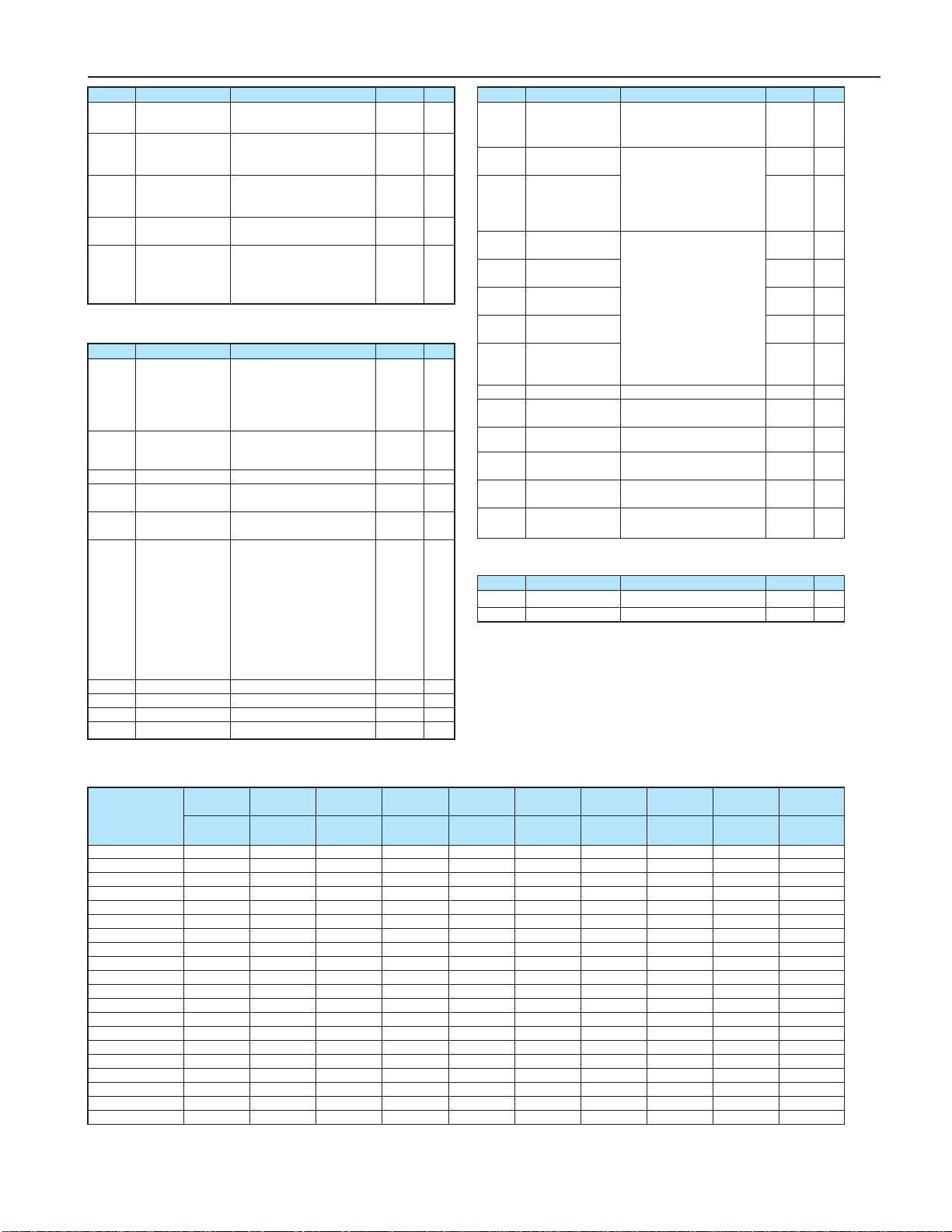

Table of Parameters

■Usage Information

■Basic Parameters

●Operational Frequency Parameter

FC 0.0

●4 Automatic Functions

AUH -

AU1 0

AU2 0

AU4 0

●Other Basic Parameters

CMOd 1

FMOd 0

FMSL 0

FM -

TyP 0

Fr 0

ACC 10.0

dEC 10.0

FH 60.0

UL 60.0

LL 0.0

VL 60.0

VLV 200/400

Title Function Adjustment range

Default setting

Note

Item Contents Item Contents

Date of setting/Name Customer name/End user name

Combined machine/Application

Machine nomenclature/product number

Motor manufacturer/Nomenclature

Motor capacity/Ratings

Inverter nomenclature/quantity HF-321-

Inverter product number/Serial number

Usage option Peripheral equipment used

Used control terminal blockNote P24V, DRV, OM, FRQ, COM, FA, FB, FC, +V, VRF, VRF2, COM, PCS, DFL, DFM, DFH, FR, RR, RST, COM

Used main circuit/SwitchNote R, S, T, U, W, E/G, P, PR, N, PI VRF (V, I), FRQ (V, I), SW1 (SOURCE, PLC, SINK)

*Fill in as necessary

Note: Circle the symbol of terminal block used.

Operation

frequency of

operation panel

LL - UL (Hz)

Title Function Adjustment range

Default setting

Note

History function

Automatic

acceleration/

deceleration

Automatic torque

boost

Automatic function

setting

Displays parameters in

groups of five in the reverse

order to that in which their

settings were changed.

(*Possible to edit)

0: Disabled (manual)

1: Automatic

2: Automatic (only at

acceleration)

0: Disabled

1: Automatic torque boost +

auto-tuning

2: Vector control+ auto-tuning

3: Energy saving+ auto-tuning

0: Disabled

1: Coast stop

2: 3-wire operation

3: External input UP/DOWN

setting

4: 4-20mA current input

operation

Title Function Adjustment range

Default setting

Note

Meter selection

Meter adjustment

Default setting

Forward/reverse

run selection

(Operation panel

operation)

Acceleration time 1

Deceleration time 1

Maximum frequency

Upper limit frequency

Lower limit frequency

Base frequency 1

Base frequency voltage 1

0: Output frequency

1: Output current

2: Set frequency

3: DC voltage

4:

Output voltage command value

5: Input power

6: Output power

7: Torque

8: Torque current

9: Motor cumulative load factor

10:

Inverter cumulative load factor

11: Braking resistor cumulative

load factor

12:Frequency setting value

(after PID)

13:VRF Input value

14:VRF2 Input value

15:Fixed output 1 (Output

current: 100%)

16:Fixed output 2 (Output

current: 50%)

17:Fixed output 3 (Other than

the output current: 100%)

18:Serial communication data

19:For adjustments (FM set

value is displayed.)

-

0: -

1: 50Hz default setting

2: 60Hz default setting

3: Don't choose

4: Trip record clear

5:

Cumulative operation time clear

6:

Initialization of type information

7: Don't choose

8: Standard default setting

(Initialization)

9: Cumulative fan operation

time record clear

0: Forward run

1: Reverse run

2: Forward run

(F/R switching possible)

3: Reverse run

(F/R switching possible)

0.0-3200 (s)

0.0-3200 (s)

30.0-500.0 (Hz)

0.5 - FH (Hz)

0.0 - UL (Hz)

25.0-500.0 (Hz)

200V class: 50-330 (V)

400/600V class: 50-660 (V)

Title Function Adjustment range

Default setting

Note

Command mode

selection

Frequency setting

mode selection 1

0: Terminal board

1: Operation panel

0: Built-in potentiometer

1: VRF

2: VRF2

3: Operation panel

4: Serial communication

5: UP/DOWN from external

contact

6: VRF+ VRF2 (Override)

Monitor Display

LED display on the control panel indicates numbers and

alphabets as below.

LED Display (Numbers)

LED Display (Alphabet)

0123456789-

0123456789-

Aa Bb C c Dd Ee Ff Gg H h I i Jj Kk Ll

AbCcdEFGHhIij L

Mm Nn O o Pp Qq Rr Ss Tt Uu Vv Ww Xx Yy Zz

MnOoPqrStUv y

TD-16

LCI FURNACES - TPSI

16

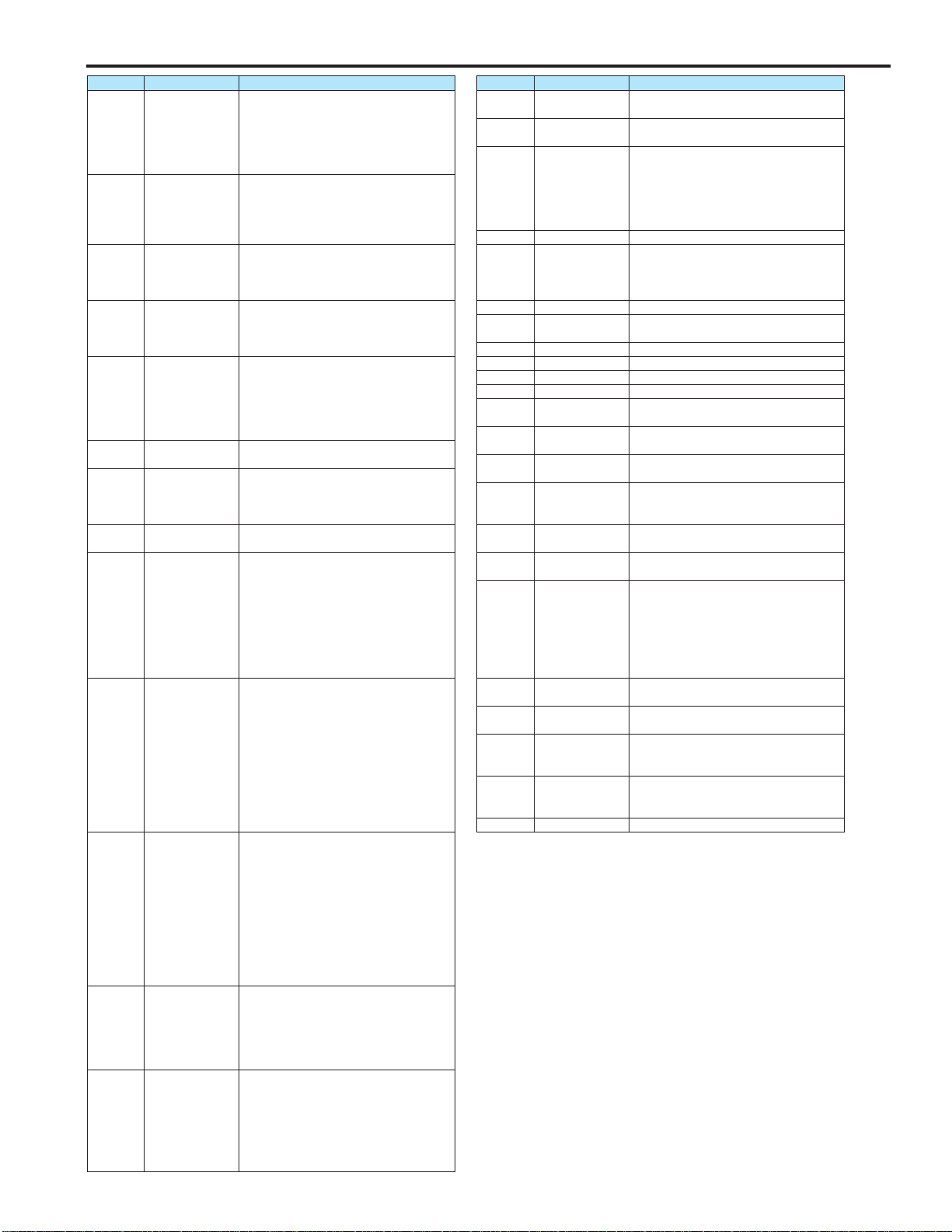

Table of Parameters

Pt 0

Vb *1

THR 100

OLM Valid

Sr1 5.0

Sr2 10.0

Sr3 15.0

Sr4 20.0

Sr5 30.0

Sr16 40.0

Sr7 50.0

F--- -

Gr.U -

nExtended Parameters

lInput/Output Parameters

F100 0.0

F101 0.0

F102 2.5

F105 1

F109 0

F110 1

F111 2

F112 3

F113 10

F114 6

F115 7

F116 8

F117 9

F118 5

F130 254

F131 14

F132 10

F137 255

F138 255

F139 0

F167 2.5

F170 60.0

F171 200/400

F172 *1

F173 100

F185 150

lFrequency Parameters

F200 0

F201 0

F202 0.0

F203 100

F204 60.0

F207 1

F210 0

F211 0.0

F212 100

F213 60.0

F240 0.5

F241 0.0

F242 0.0

F250 0.0

F251 50

F252 1.0

F254 0

F256 0.0

F260 5.0

F261 0

F262 0

Title Function Adjustment range

Default setting

Note

V/F control mode

selection 1

Torque boost 1

Motor electronic thermal

protection level 1

Electronic-thermal

protection

characteristic

selection

Preset-speed

operation frequency 1

Preset-speed

operation frequency 2

Preset-speed

operation frequency 3

Preset-speed

operation frequency 4

Preset-speed

operation frequency 5

Preset-speed

operation frequency 6

Preset-speed

operation frequency 7

Extended parameters

Automatic edit function

0:

V/F constant

1: Variable torque

2:

Automatic torque boost control

3: Sensorless Vector control

4: Automatic energy-saving

5: Dynamic automatic energy-

saving (for fans and pumps)

6: Don't choose

0.0 - 30.0 (%)

10 - 100 (%/A) *2

LL - UL (Hz)

LL - UL (Hz)

LL - UL (Hz)

LL - UL (Hz)

LL - UL (Hz)

LL - UL (Hz)

LL - UL (Hz)

-

-

Title Function Adjustment range

Default setting

Note

Frequency priority

selection

VRF input point 1

setting

VRF input point 1

frequency

VRF input point 2

setting

VRF input point 2

frequency

Frequency setting

mode selection 2

VRF2 input point 1

setting

VRF2 input point 1

frequency

VRF2 input point 2

setting

VRF2 input point 2

frequency

Starting frequency setting

Operation starting frequency

Operation starting

frequency hysteresis

DC braking starting

frequency

DC braking current

DC braking time

Motor shaft fixing

control

Auto-stop in case of lower-

limit frequency continuous

operation time

Jog run frequency

Jog run stopping

pattern

Panel jug run mode

0:

fMod

(Switchable to

F207

by the input terminal)

1:

F207 (F207 for output frequencies

equal to or lower than 1.0 Hz)

0-100 (%)

0.0-500.0 (Hz)

0-100 (%)

0.0-500.0 (Hz)

0: Built-in potentiometer

1: VRF

2: VRF2

3: Serial communication

4: Serial communication

5:

External contact point up-down

6: VRF + VRF2 (Override)

0-100 (%)

0.0-500.0 (Hz)

0-100 (%)

0.0-500.0 (Hz)

0.5-10.0 (Hz)

0.0-

FH

(Hz)

0.0-

FH

(Hz)

0.0-

FH

(Hz)

0.0-100 (%/A) *2

0.0- 20.0 (s)

0: Disabled

1: Enabled

0.0: None

0.1~600.0 (s)

F240

~20.0 (Hz)

0: Slowdown stop

1: Coast stop

2: DC braking

0: Disabled

1: Panel jog run mode enabled

Title Function Adjustment range

Default setting

Note

Low-speed signal

output frequency

Speed reach setting

frequency

Speed reach detection band

Priority selection

(both FR-COM, RR-

COM are ON)

Analog/contact input

function selection

(VRF/VRF2 terminal)

Always-active

function selection

Input terminal

selection 1 (FR)

Input terminal

selection 2 (RR)

Input terminal

selection 3 (RST)

Input terminal

selection 4 (DFL)

Input terminal

selection 5 (DFM)

Input terminal

selection 6 (DFH)

Input terminal

selection 7 (VRF2)

0.0 -

FH

(Hz)

0.0 -

FH

(Hz)

0.0 -

FH

(Hz)

0: Reverse

1: Stop

0: VRF - analog input VRF2 -

anolog input

1: VRF - anolog input VRF2 -

contact input (Sink)

2: VRF - analog input VRF2 -

contact input (Source)

3: VRF - contact input (Sink)

VRF2 - contact input (Sink)

4: VRF - contact input (Source)

VRF2 -

contact input (Source)

0-64 (ST)

0-64 (FR)

0-64 (RR)

0-64 (RST)

0-64 (DFL)

0-64 (DFM)

0-64 (DFH)

5-17 (DFHM)

Title Function Adjustment range

Default setting

Note

Input terminal

selection 8 (VRF)

Output terminal

selection 1A (RY-RC)

Output terminal

selection 2A (DRV-OM)

Output terminal

selection 3 (FL)

Output terminal

selection 1B (RY-RC)

Output terminal

selection 2B (DRV-OM)

Output terminal logic

selection (RY-RC,

DRV-OM)

Frequency command

agreement detection range

Base frequency 2

Base frequency

voltage 2

Torque boost quantity 2

Motor electronic-thermal

protection level 2

Stall prevention level 2

5-17 (AD2)

0-255

0-255

0-255

0-255

0-255

0:

F130

and

F137

,

F131

and

F138

1:

F130

or

F137

,

F131

and

F138

2:

F130

and

F137

,

F131

or

F138

3:

F130

or

F137

,

F131

or

F138

0.0 - (Hz)

25.0-500.0 (Hz)

200V class: 50-330 (V)

400V class: 50-660 (V)

0.0-30.0 (%)

10-100 (%/A) *2

10~199 (%/A) *2200: Disabled

Setting

Overload Overload

value

protection stall

0 Valid Invalid

1 Standard Valid Valid

2 motor Invalid Invalid

3 Invalid Valid

4 AF Valid Invalid

5 motor Valid Valid

6 (inverter Invalid Invalid

7 motor) Invalid Valid

*1: Default setting of the parameter differs by each inverter capacity. Refer to "Default settings by Inverter Rating" table on page 19 for actual values.

*2: Unit displayed may be selected by parameter F701 (Unit selection).

17

Table of Parameters

F264 0.1

F265 0.1

F266 0.1

F267 0.1

F268 0.0

F269 1

F270 0.0

F271 0.0

F272 0.0

F273 0.0

F274 0.0

F275 0.0

F287 60.0

F288 0.0

F289 0.0

F290 0.0

F291 0.0

F292 0.0

F293 0.0

F294 0.0

●Operation Mode Parameters

F300 4.0

F301 0

F302 0

F303 0

F304 0

F305 1

F307 3

F308 *1

F309 *1

F311 0

F312 1

F316 1

F320 0

F323 10

F342 0

F343 3.0

F344 0.05

F345 3.0

F346 0.10

F359 0

F360 0

F362 0.30

F363 0.20

F366 0.00

●Torque Boost Parameters 1

F400 0

F401 *1

F402 *1

F415 *1

F416 *1

F417 *1

F418 40

F419 20

●Input/Output Parameters 2

F470 128

F471 128

F472 128

F473 128

●Torque Boost Parameters 2

F480 100

F485 100

F492 100

F494 *1

●Acceleration/Deceleration Time Parameters

F500 10.0

F501 10.0

F502 0

Title Function Adjustment range

Default setting

Note

Input from external contacts

- UP response time

Input from external

contacts - UP

frequency step width

Input from external contacts

- DOWN response time

Input from external

contacts - DOWN

frequency step width

Initial value of

UP/DOWN frequency

Saving of changed

value of UP/DOWN

frequency

Jump frequency 1

Jumping width 1

Jump frequency 2

Jumping width 2

Jump frequency 3

Jumping width 3

Preset-speed operation

frequencies 8

Preset-speed operation

frequencies 9

Preset-speed operation

frequencies 10

Preset-speed operation

frequencies 11

Preset-speed operation

frequencies 12

Preset-speed operation

frequencies 13

Preset-speed operation

frequencies 14

Preset-speed operation

frequencies 15 (Fire-speed)

0.0-10.0 (s)

0.0-

FH

(Hz)

0.0-10.0 (s)

0.0-

FH

(Hz)

LL

-

UL

(Hz)

0: Not changed

1: Setting of

F268

changed

when power is turned off

0.0-

FH

(Hz)

0.0-30.0 (Hz)

0.0-

FH

(Hz)

0.0-30.0 (Hz)

0.0-

FH

(Hz)

0.0-30.0

LL

-

UL

(Hz)

LL

-

UL

(Hz)

LL

-

UL

(Hz)

LL

-

UL

(Hz)

LL

-

UL

(Hz)

LL

-

UL

(Hz)

LL

-

UL

(Hz)

LL

-

UL

(Hz)

Title Function Adjustment range

Default setting

Note

Carrier frequency

control mode

selection

Drooping gain

Drooping insensitive

torque band

Braking mode

selection

Release frequency

Release time

Creeping frequency

Creeping time

PID control wait time

PID control

Proportional gain

Integral gain

Differential (D) gain

0: Carrier frequency not

reduced automatically

1: Carrier frequency reduced

automatically

2:

Carrier frequency not reduced

automatically

Support for 400V models

3: Carrier frequency reduced

automaticallySupport for

400V models.

0-100%

0-100%

0: Disabled

1: Enabled (forward run)

2: Enabled (reverse run)

3: Enabled (operating direction)

F240

-20.0 (Hz)

0.00-2.50

F240

-20.0 (Hz)

0.00-2.50

0-2400 (s)

0: Disabled, 1: Enabled

0.01-100.0

0.01-100.0

0.00-2.55

Title Function Adjustment range

Default setting

Note

Auto-tuning

Slip frequency gain

Motor constant #1

(primary resistance)

Motor rated current

Motor no-load current

Motor rated rotational speed

Speed control

response coefficient

Speed control

stability coefficient

0: Auto-tuning disabled

(use of internal parameters)

1:

Application of individual settings

of

F402

(after execution: 0)

2: Auto-tuning enabled

(after execution: 0)

0-150 (%)

0.0-30.0 (%)

0.1-100.0 (A)

10-90 (%)

100-32000 (min-1)

1-150

1-100

Title Function Adjustment range

Default setting

Note

VRF input bias

VRF input gain

VRF2 input bias

VRF2 input gain

0-255

0-255

0-255

0-255

Title Function Adjustment range

Default setting

Note

Exciting

strengthening

coefficient

Stall cooperation

gain at field

weakening zone 1

Stall cooperation

gain at field

weakening zone 2

Motor adjustment

factor

100-130 (%)

10-250

50-150

0-200

Title Function Adjustment range

Default setting

Note

Acceleration time 2

Deceleration time 2

Acceleration/

deceleration 1

pattern

0.0-3200 (s)

0.0-3200 (s)

0: Linear,

1: S-pattern 1,

2: S-pattern 2

Title Function Adjustment range

Default setting

Note

PWM carrier

frequency

Auto-restart control

selection

Regenerative power

ride-through control

/Deceleration stop

Retry selection

(number of times)

Dynamic braking

selection

Overvoltage limit

operation

(Slowdown stop

mode selection)

Supply voltage

correction (output

voltage limited)

Dynamic braking

resistance

Dynamic braking

resistor capacity

Reverse-run prohibition

Random mode

2.0-16.0 (kHz)

0: Disabled

1:

At auto-restart after momentary stop

2:

When turning ST-COM on or off

3: At auto-restart or when

turning ST-COM on or off

4: At start-up

0: Disabled

1: Enabled

2: Slowdown stop

0: None,

1-10 times

0: Dynamic braking disabled

1: Dynamic braking enabled,

over-load protection enabled

0: Enabled

1: Prohibited

2:

Enabled (forced quick deceleration)

3: Enabled (dynamic quick

deceleration)

0: Supply voltage uncorrected,

output voltage limited

1: Supply voltage corrected,

output voltage limited

2: Supply voltage uncorrected,

output voltage unlimited

3: Supply voltage corrected,

output voltage unlimited

1.0-1000 (:)

0.01-30.00 (kW)

0:

Forward/reverse run permitted

1: Reverse run prohibited

2: Forward run prohibited

0: Disabled,

1: Enabled

TD-18

18

Table of Parameters

F503 0

F504 1

F505 0.0

F506 10

F507 10

F510 10.0

F511 10.0

F512 0

F513 0.0

●Protection Parameters

F601 150

F602 0

F603 0

F604 1.0

F605 0

F607 60

F608 1

F610 0

F611 0

F612 0

F613 0

F615 0

F616 150

F618 0.5

F619 10

F621 610

F626 *1

F627 1

F633 0

F634 3

F669 0

F676 0

F677 800

F691 1

F692 0

●Operation Panel Parameters

F700 0

F701 1

F702 0.00

F705 1

F706 0.00

F707 0.00

F708 0

F710 0

F719 1

F721 0

Title Function Adjustment range

Default setting

Note

Acceleration/

deceleration

2 pattern

Selecting an

acceleration/

deceleration pattern

Acceleration/deceleration 1

and 2 switching frequency

S-pattern lower-limit

adjustment amount

S-pattern upper-limit

adjustment amount

Acceleration time 3

Deceleration time 3

Acceleration/

deceleration

3 pattern

Acceleration/deceleration 2

and 3 switching frequency

0: Linear,

1: S-pattern 1,

2: S-pattern 2

1:

Acceleration/deceleration 1 pattern

2:

Acceleration/deceleration 2 pattern

3:

Acceleration/deceleration 3 pattern

0.0-

UL

(Hz)

0-50%

0-50%

0.0-3200 (s)

0.0-3200 (s)

1: Linear,

2: S-pattern 1,

3: S-pattern 2

0.0-

UL

(Hz)

Title Function Adjustment range

Default setting

Note

Annual average

ambient temperature

(calculation for life

alarms)

Logic output/pulse

train output selection

(DRV-OM)

Pulse train output

function selection

(DRV-OM)

Maximum numbers

of pulse train

Inclination

characteristic of

analog output

Bias of analog output

1: -10 ~ +10°C

2: 11~20°C

3: 21~30°C

4: 31~40°C

5: 41~50°C

6: 51~60°C

0: Logic output

1: Pulse train output

0: Output frequency

1: Output current

2: Set frequency

3: DC voltage

4:

Output voltage command value

5: Input power

6: Output power

7: Torque

8: Torque current

9: Motor cumulative load factor

10:

Inverter cumulative load factor

11: Braking reactor cumulative

load factor

12: Frequency setting value

(after PID)

13: VRF Input value

14: VRF2 Input value

15: Fixed output 1

(Output current: 100%)

16: Fixed output 2

(Output current: 50%)

17: Fixed output 3 (Other than

the output current: 100%)

500-1600 (PPS)

0:

Negative inclination (downward slope)

1:

Positive inclination (upward slope)

0-100%

Title Function Adjustment range

Default setting

Note

Prohibition of change

of parameter setting

Current/voltage

display mode

Frequency free unit

magnification

Inclination

characteristic of free

unit display

Bias of free unit

display

Free step 1

(pressing a panel

key once)

Free step 2 (panel

display)

Standard monitor

display selection

Canceling of operation

command when standby

terminal (ST) is turned off

Selection of operation

panel stop pattern

0: Permitted,

1: Prohibited

0: %

1: A (ampere)/V (volt)

0.00: Free unit display disabled

(display of frequency)

0.01-200.0 (times)

0:

Negative inclination (downward slope)

1:

Positive inclination (upward slope)

0.00-

FH

(Hz)

0.00: Disabled

0.01-

FH

(Hz)

0: Disabled

1-255

0: Operation frequency

(Hz/free unit)

1: Frequency command

(Hz/free unit)

2: Output current (%/A)

3: Inverter rated current (A)

4: Inverter load factor (%)

5: Output power (kW)

6: Frequency command after

PID control (Hz/free unit)

7: Optional item specified from

an external control unit

0: Operation command

canceled (cleared)

1:

Operation command retained

0: Slowdown stop

1: Coast stop

Title Function Adjustment range

Default setting

Note

Stall prevention level 1

Inverter trip retention

selection

Emergency stop

selection

Emergency DC

braking time

Output phase failure

detection mode

selection

Motor

150%-overload

time limit

Input phase failure

detection mode selection

Small current

trip/alarm selection

Small current detection current

Small current detection time

Detection of output

short-circuit during

start-up

Over-torque

trip/alarm selection

Over-torque

detection level

Over-torque

detection time

Over-torque

detection level

hysteresis

Cumulative operation

time alarm setting

Overvoltage limit

operation level

Undervoltage

trip/alarm selection

*3

Trip at VRF low level

input mode

10-199 (%/A)

200 (Deactivated)

0: Cleared if power is turned off

1:

Retained even if power is turned off

0: Coast stop

1: Slowdown stop

2: Emergency DC braking

0.0-20.0 (s)

0: Disabled

1: At start-up (Only one time