Page 1

v.06.18.20

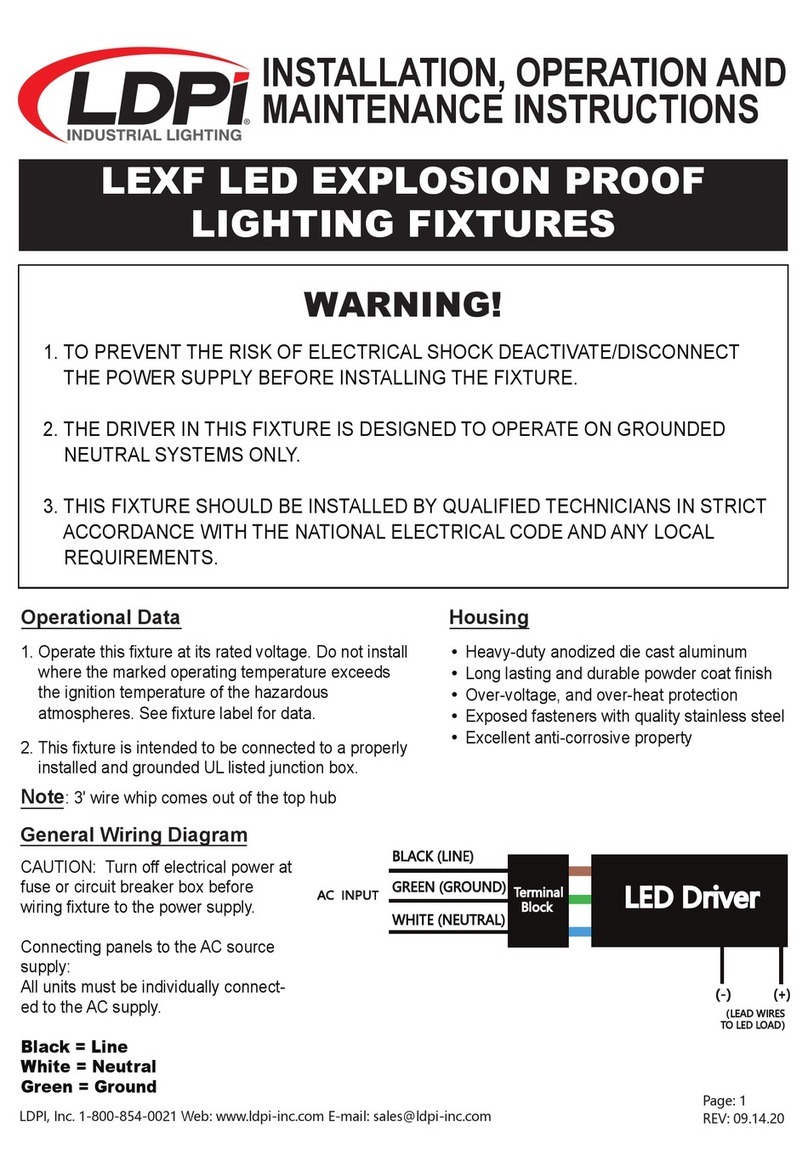

INSTALLATION, OPERATION AND

MAINTENANCE INSTRUCTIONS

LEHL2 LED HAZARDOUS LOCATION

LIGHTING FIXTURES

Class I Div. 2 (Grps A,B,C,D) / Class II Div. 1 (Grps E,F,G)

Class II Div. 2 (Grps F,G) / Class III Div. 1

General Safety Information

WARNING! RISK OF ELECTRICAL SHOCK

CAUTION! RISK OF INJURY AND FIRE

To reduce the risk of death, personal injury or property damage from fire, electic shock, falling parts, cut/abrasions and other

hazards, read all warnings and instructions included with and on the luminaire box and all luminaire labels.

Before installing, servicing or performing routine maintenance on this luminaire, follow these general precautions.

Commercial installation, service and maintenance of luminaires should be performed by a qualified licensed

electrician.

DO NOT INSTALL DAMAGED PRODUCT!

This luminaire is intended to be connected to a properly installed and grounded UL listed junction box.

Ensure the supply voltage is the same as the luminaire voltage.

Do not install in a location where the marked operating temperatures exceed the ignition temperatures of the

hazardous atmosphere.

Do not operate in ambient temperatures above those indicated on the luminaire nameplate.

All gasket seals must be clean and undamaged.

•

•

•

•

•

•

Turn off electrical power at fuse or circuit breaker box before wiring luminaire to the power supply.

Turn off the power when any maintenance is performed.

Verify that the supply voltage is the same as noted on the luminaire label

All electrical and grounded connections must be in accordance with the National Electrical Code and any applicable

local code and Hazardous location requirements.

All wiring connections must be capped with UL approved wire connectors.

Luminaire must be supplied by a wiring system with a equipment grounding conductor.

•

•

•

•

•

•

Wear gloves and safety glasses at all times when removing luminaire from carton, installing, servicing or performing

maintenance.

Avoid direct eye exposure to the light source when luminaire is turned on.

Account for small parts and pieces of packing material as these may be hazardous to children.

Keep combustible and flammable materials away from luminaire.

Minimum 194°F (90°C) Supply Conductors

•

•

•

•

•