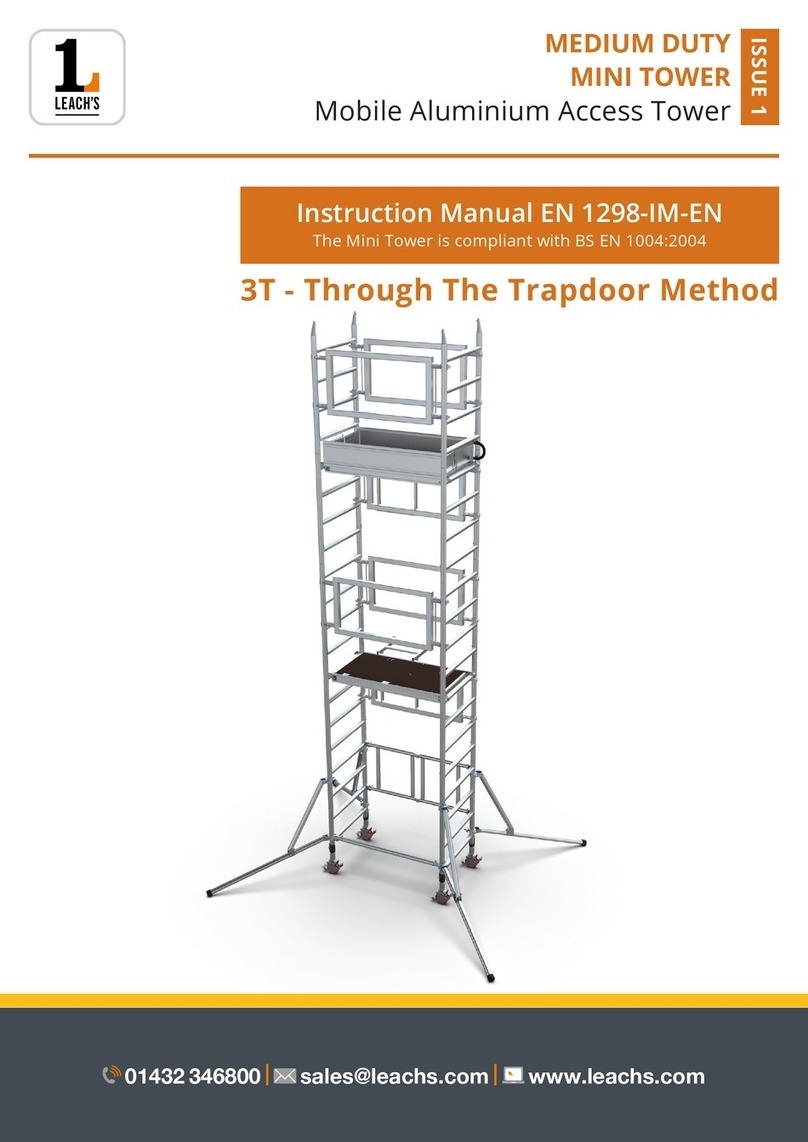

Page 3

Inspection Care & Maintenance

The equipment is designed and manufactured to the highest standards in the industry and is

stronger, more robust and safer than any comparable competitor product. Properly cared for, it will

give a long and productive service life.

•The equipment should be inspected and maintained as outlined in the “MD Tower Inspection

Procedures”. A free downloadable copy is available at www.leachs.com

•Equipment should always be inspected before and after each use.

•Whilst equipment is extremely robust, care should be exercised in loading, transporting and

handling components to avoid damage or injury to either the equipment or persons.

•Repairs should only be carried out by LEACH'S or their authorised repairers.

•In case of any doubt as to the integrity of any items of the equipment, the part should be

withdrawn from use, quarantined and subject to detailed examination to determine whether

repair or replacement is required. If returned to the factory, Lakeside Industries Limited will

provide a free of charge evaluation of any damaged components.

Safety

Check that all of the necessary components and equipment for the particular tower configuration to be

built are on site, undamaged and functioning correctly. Damaged or incorrect components must not be

used.

•Check that the surface on which the tower is to be located is capable of supporting the tower and

its payload.

•The safe working load of the tower is 2,000kg including its own weight. The maximum safe

working load of any individual platform is 282 kg evenly distributed.

•If the tower is to be used in an application outside the scope of EN1004, contact your supplier or

the manufacturer, Lakeside Industries Limited, for advice on loadings. Tel: +44 1527 500577 or

•Towers must always be climbed from the inside using the built in ladders only. If the work

carried out from the tower requires frequent carrying of equipment and materials up or down the

tower, a stair tower should be used in preference to a ladderspan tower.

•The tower must be levelled when erected using the adjustable jack or castor legs.

•Two or more persons are required for the safe erection and dismantling of a tower.

•It is recommended that the tower be tied in when left unattended.