9

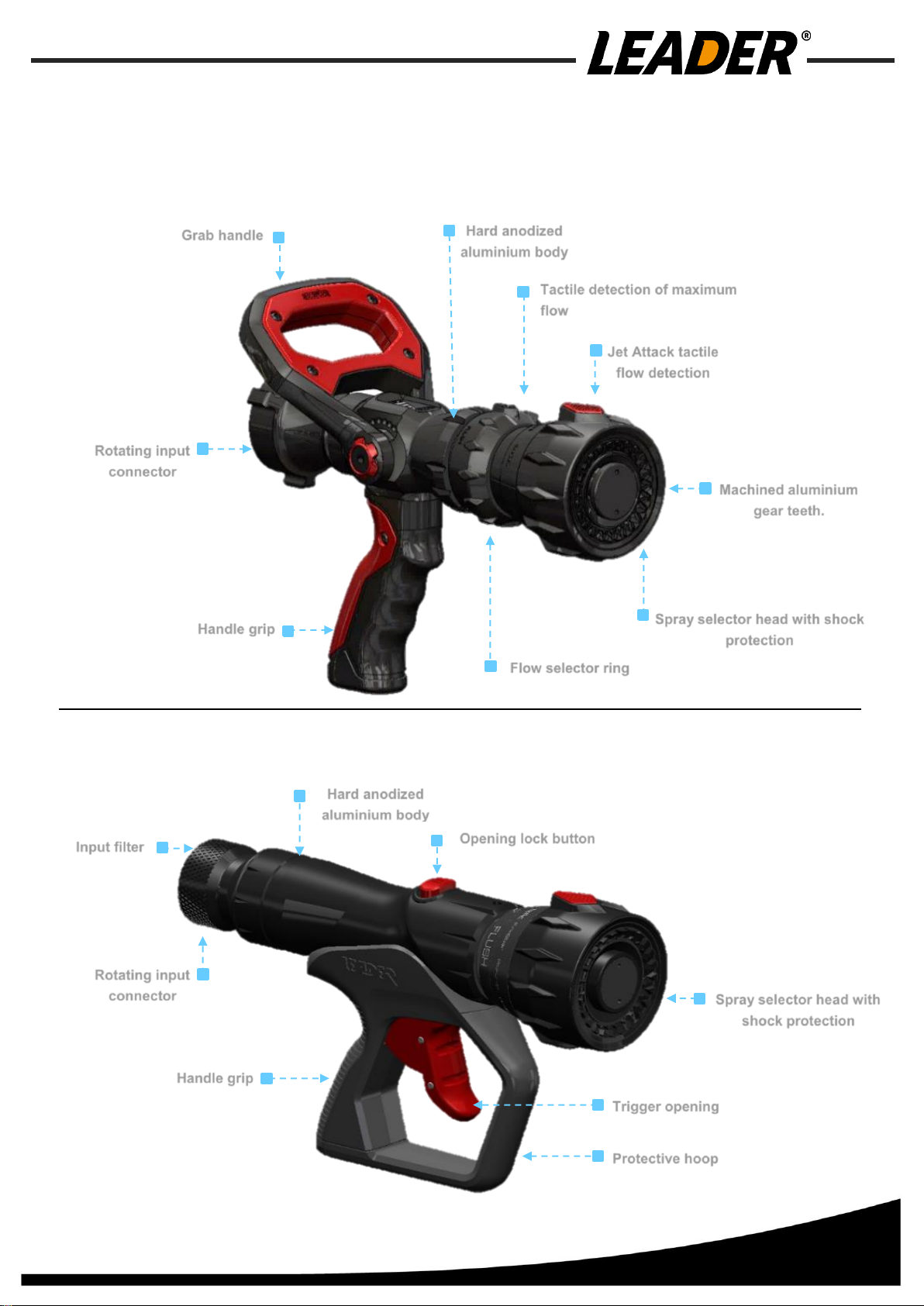

➢ALUMINIUM body with a Standard handle:

▪AGS T5 aluminium alloy construction.

▪Protection against mechanical and chemical attack by 50μ hard

anodization and Teflon impregnation.

▪Protection against shocks thanks to its heat and cold resistant

polyurethane head sheath. Excellent thermal insulation.

▪Its ergonomic grip is made of non-slip polyamide.

▪Stainless steel pins and screws.

▪Ergonomic handle.

➢ALUMINIUM body with a Trigger handle:

▪AGS T5 aluminium alloy construction.

▪Protection against mechanical and chemical attack by 50μ hard

anodization and Teflon impregnation.

▪Protection against shocks thanks to its heat and cold resistant

polyurethane head sheath.

Excellent thermal insulation.

▪Its ergonomic grip is made of non-slip polyamide.

▪Protective hoop (optional).

▪Stainless steel pins and screws.

▪Ergonomic handle.

➢Interchangeable handles:

▪Facilitates identifying the device after an intervention.

▪Possibility for users to choose the colour of the

handle grip between Red, Yellow, Orange, Blue, and

Green.

This option is valid on devices having a standard

aluminium handle.