Introduction 1

7

Building Technologies A6V10359489_a_en

CPS Fire Safety 30.09.2016

1Introduction

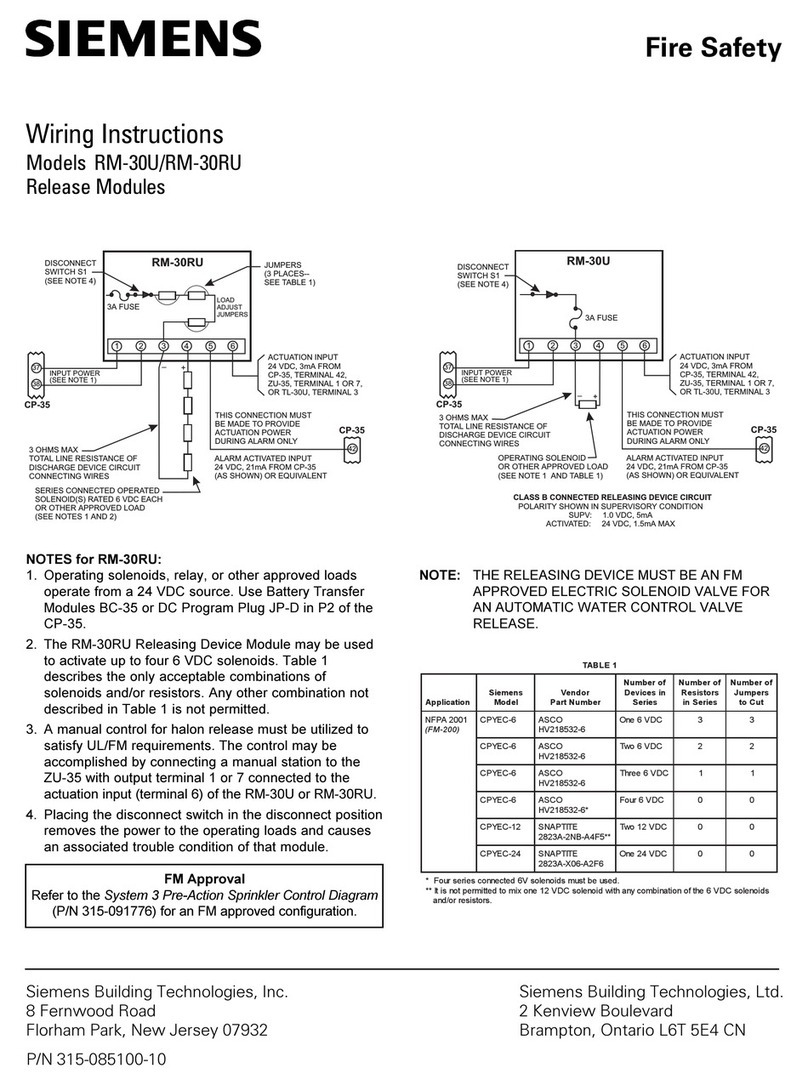

Siemens fire safety and security products are designed to work together. While

there are many occasions where only one product may be used in a facility, when

combined our products create a robust and flexible set of architectural and

connectivity solutions. The possible combinations of Danger Management Systems

(DMS), network choices, and subsystems used in any given plant are extensive.

However, the time involved with commissioning tasks can be substantial.

With the aim of reducing time spent on configuration, Siemens BT FS has

developed their products so that the DMS and the networks can all be configured

with a single tool called WW8000 Composer.

The networks and subsystems supported by our Danger Management Systems are

always configured in the same way within the Composer environment.

What this document contains

This document includes the configuration procedures for the video subsystems

supported by our DMS8000 products. It discusses in detail how to configure these

systems by hand.

What this document does not contain

Each DMS carries a different set of technical and behavioural characteristics that

interact with the networks and subsystems. These differences typically appear as

additional tabs in the network and subsystem work areas of Composer. However,

since these tabs are always associated with attributes specific to the DMS being

used, they are not discussed in this manual. This information can be found in the

corresponding product manual.

Reference documents are listed in the Resource Information document (see About

this document [➙4]).

1.1 Additional documents

Depending on your level of experience with Composer, and the architectural

solutions available with our products, as well as where you are in the

commissioning process, there are a number of additional documents that you may

find useful. If you need a document that you do not have, you can download it on

the Siemens Intranet.

Please see the following descriptions of relevant additional documents:

lThe Composer WW8000 Technical Manual contains mostly introductory

information for new users of Composer. In addition to general introductory

information, it contains details about several functions and shortcuts that can

be useful for users. This manual is typically included with the documentation

set that comes with each product. The document number is A6V10062401.

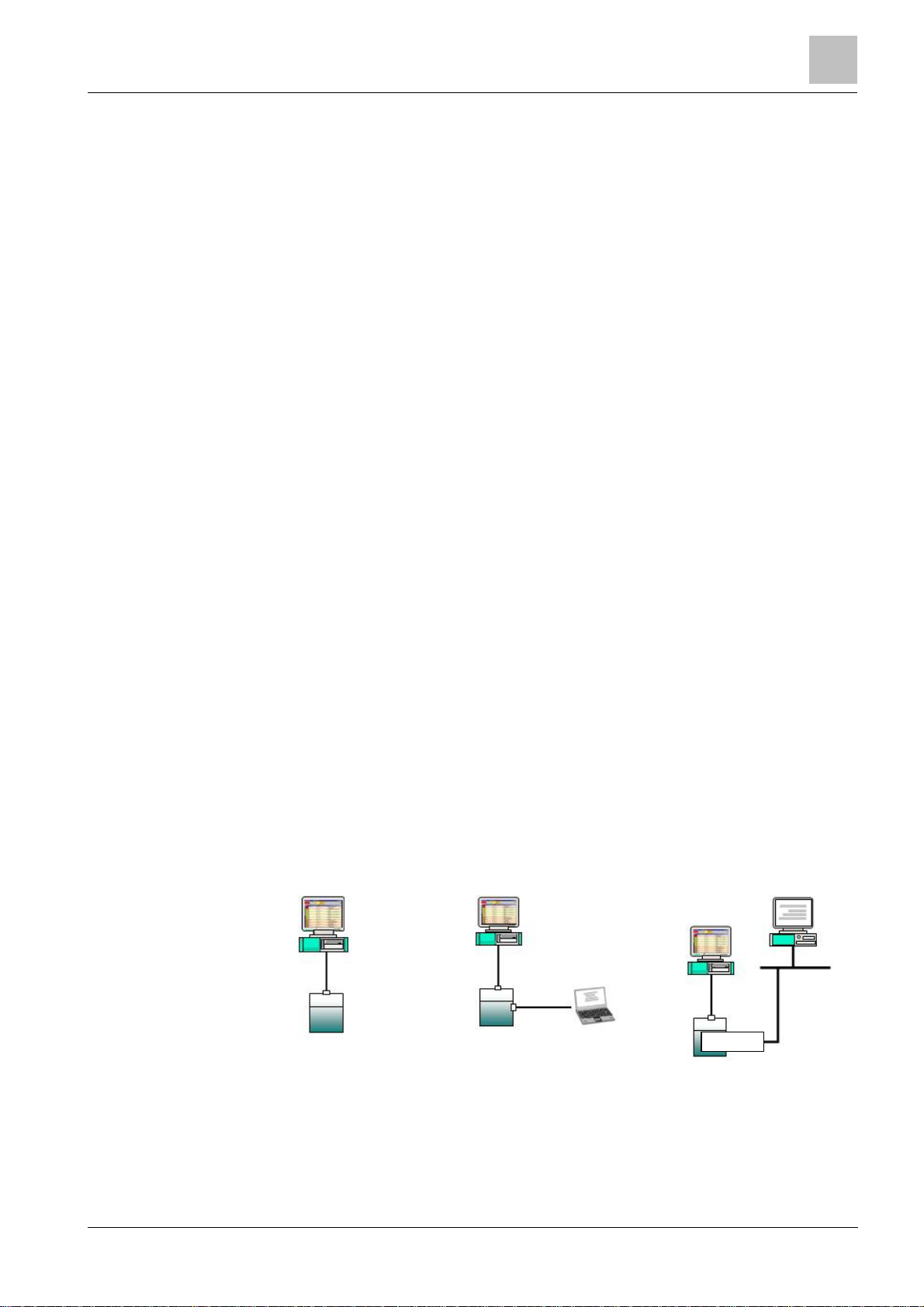

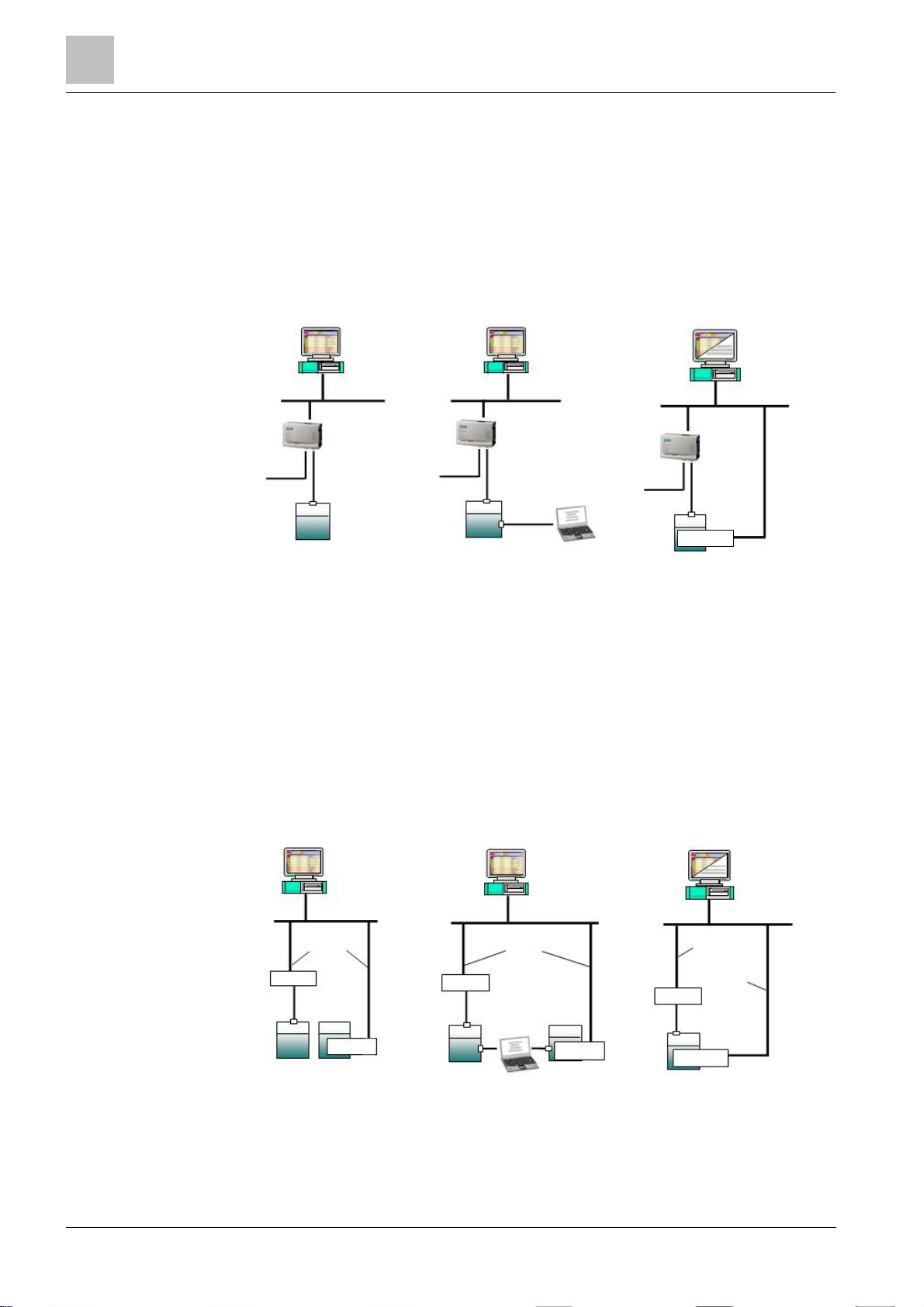

lThe Application and Planning guide (A6V10063710) shows the architectural

solutions currently available with the DMS systems, including network and

subsystem connectivity options. These documents are a kind of library of

technical solutions, and are intended primarily as sales tools, but provide an

overview of the relationships within the system that may be useful when

planning a configuration.

lThe product-specific Installation Configuration & Commissioning manual (ICC)

is the necessary complement to this manual for getting a complete view of the

configuration process. Please refer to the latest edition of the following

document:

– MM8000 ICC (A6V10062413)

– MT8001 ICC (A6V10096181)

– MK8000 ICC (A6V10062407)

– NK8000 ICC (A6V10062437)