4

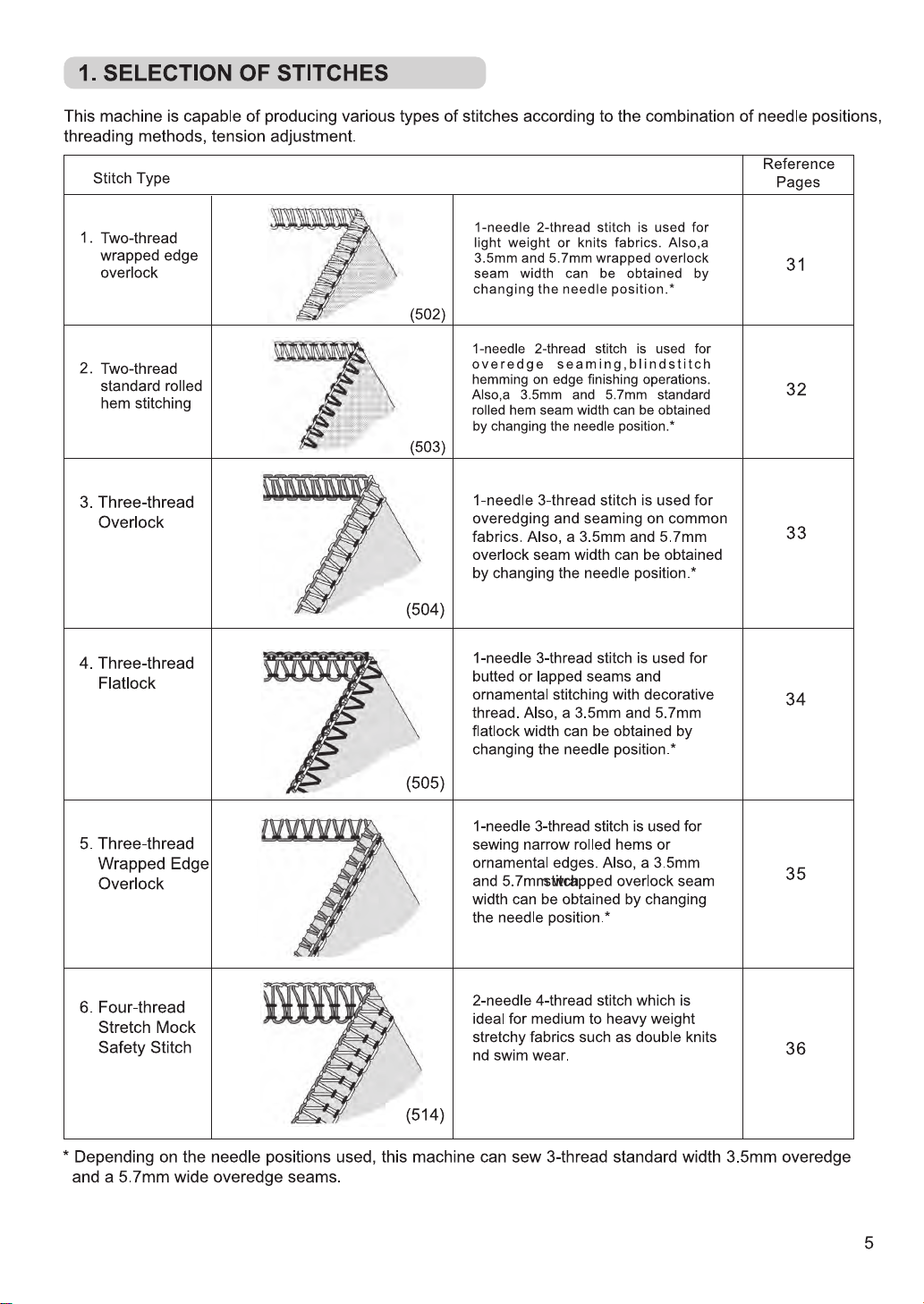

1. Selection of Stitches ........................................5

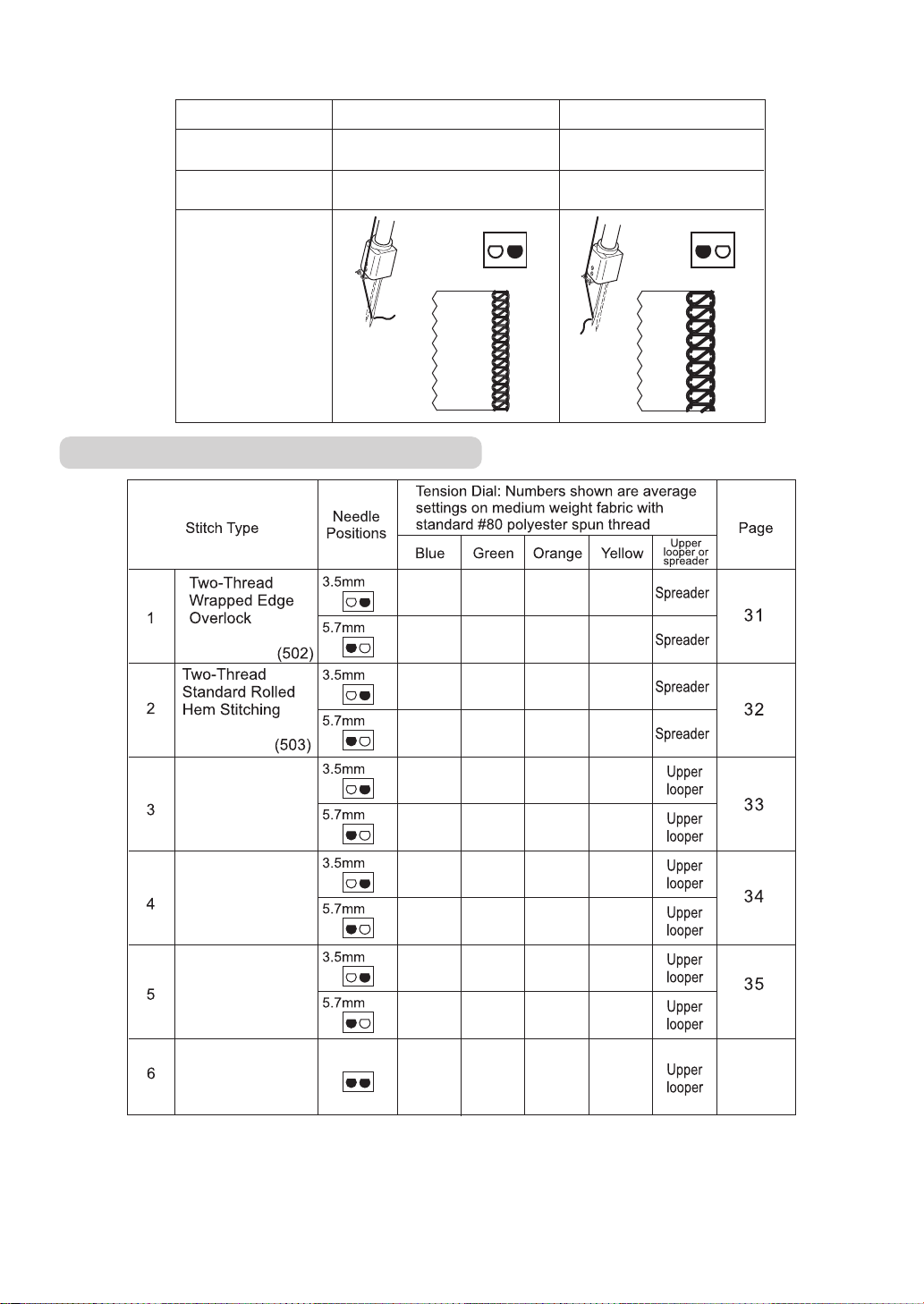

2. Handy Reference Chart ..................................6

3. Accessories ...................................................7

4. Needle Information ..........................................7

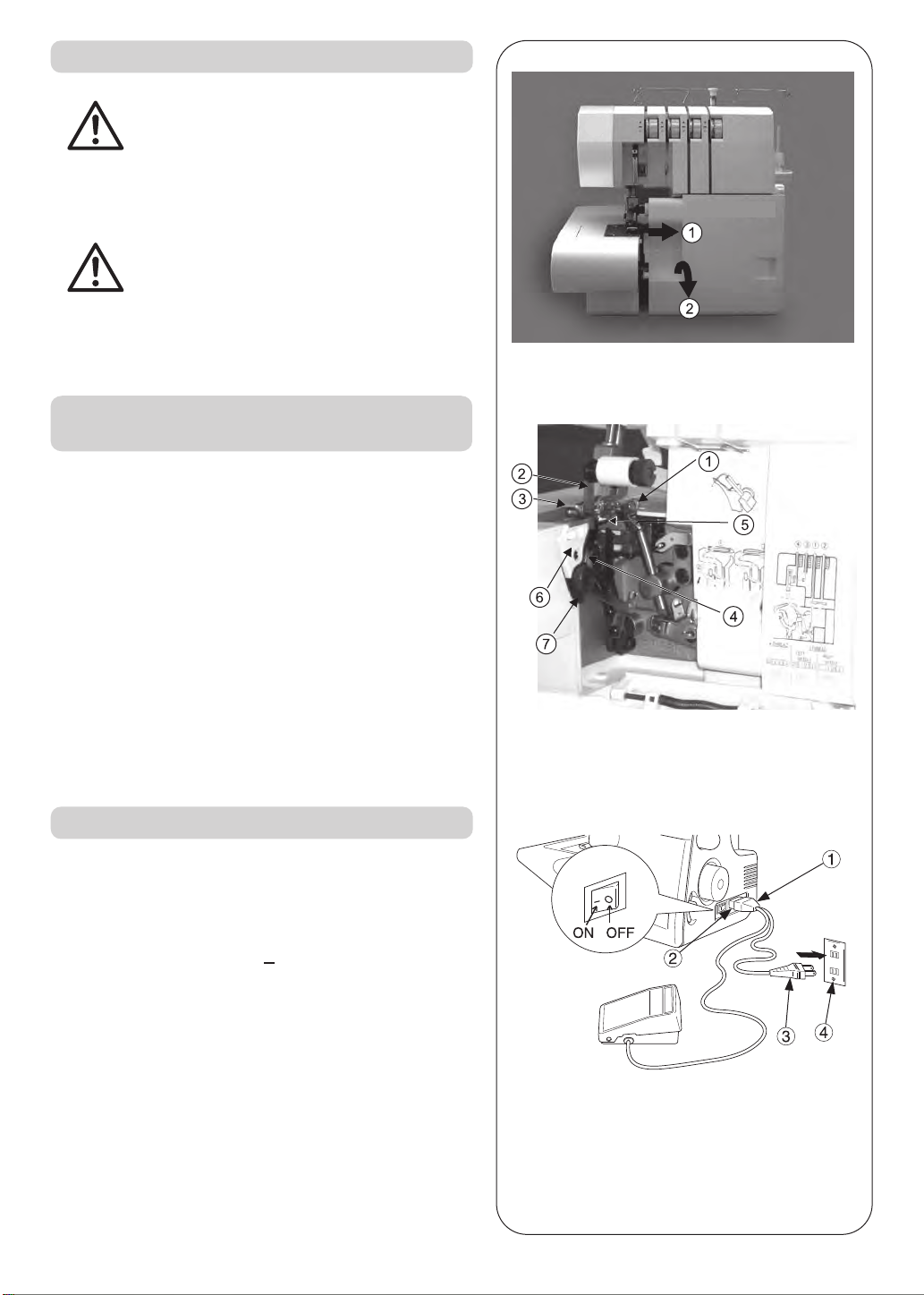

5. Principal Parts .................................................8

6. How to Open Looper Cover .............................9

7. Principal Parts Behind Looper Cover ..............9

8. Preparation Prior to Sewing ............................9

9. Preparation for Threading ..............................10

•Setting up the thread guide holder ...............10

10. How to Remove and Insert Needles...............11

•To remove needle(s) ....................................11

•To insert needle(s) .......................................11

11. Threading the Machine ..................................12

•Threading diagram .......................................12

•Understanding the color code ......................12

•To thread the machine correctly ...................12

1) Threading the upper looper (Orange) .......12

2) Threading the lower looper (Yellow) ..........14

3) Threading the right needle (Green) ...........16

4) Threading the left needle (Blue) ................18

•Important threading information ...................19

12. How to Change Threads / Tie on Method ......20

13. How to Adjust the Stitch Length ....................21

14. How to Adjust the Seam Width ......................21

•

Width adjustment by changing needle position

...21

•

Width adjustment with adjustment knob

............21

15. How to Adjust the Presser Foot Pressure .....22

16. Differential Feed

(If your machine has this device) ...................23

•Gathered overedge ......................................23

•Stretch overedge .........................................24

17. How to Disengage Movable Upper Knife .......25

19. Free Arm Sewing (Tubular Work) ..................27

20. Standard Overedge and Rolled Hem Stitching .....28

•To sew standard overedge ...........................28

•To sew rolled hem ........................................28

21. Chaining Off and Test Sewing .......................29

25. Stitch Variations and Sewing Techniques ..... 41

•How to sew a flatlock decorative seam ....... 41

•How to sew an overlock blind hem ............ 43

•How to sew pin tucks .................................. 43

•Turning square corners .............................. 44

•Pin placement ............................................. 45

•Securing the thread chain ........................... 45

•How to reinforce a seam ............................. 46

•Braiding by chaining off .............................. 46

26. Machine Maintenance .................................. 47

•Cleaning the machine ................................. 47

•Oiling the machine ...................................... 47

•How to replace the stationary knife ............. 48

27. Troubleshooting Chart .................................. 49

28. Relationship between Cloth, Thread and Needle .... 50

29. Specification ................................................. 51

CONTENTS

Page Page

18. Converting the upper looper into spreader ...........26

24. How to Sew a Rolled Hem ..................................

23. Suggested Tension Setting ................................

2-thread wrapped edge overlock

2-thread standard rolled hem stitching .............

1)

2)

3) 3-Thread Overlock ........................................

4) 3-Thread Flatlock ..........................................

5) 3-Thread Wrapped Edge Overlock ...............

6) 4-Thread Ultra Stretch Mock Safety Stitch ....

1) a. 2-thread wrapped edge overlock ..................

b. 2-thread standard rolled hem stitching .........

22. Starting and Ending Seams ................................ 30

30

30

31

31

32

33

34

35

36

37

38

38

39

39

2) a. 3-thread standard rolled hem stitching .........

b. 3-thread upper looper thread wrapped

rolled hem stitching ...........................................

●To Start a Seam .............................................

●To End a Seam ..............................................