Contents

Tel: (86)755-26434369IWebsite: www.leadshine.com

TableofContents

1. Introduction, FeaturesandApplications..................................................................1

Introduction..........................................................................................................1

Features................................................................................................................1

Applications.........................................................................................................2

2. SpecificationsandOperating Environment.............................................................2

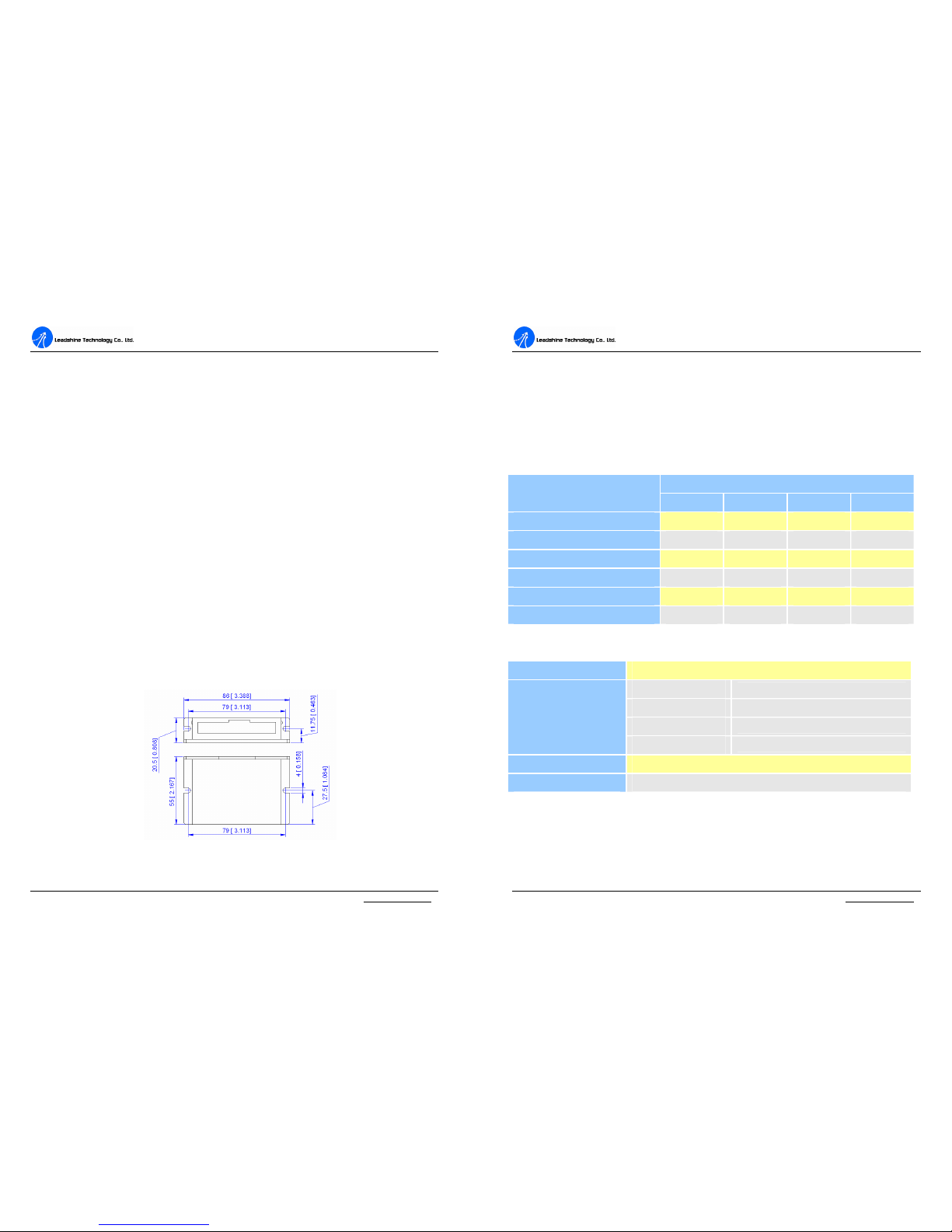

MechanicalSpecifications....................................................................................2

EliminationofHeat..............................................................................................3

ElectricalSpecifications.......................................................................................3

OperatingEnvironmentandParameters...............................................................3

3. Connections.............................................................................................................4

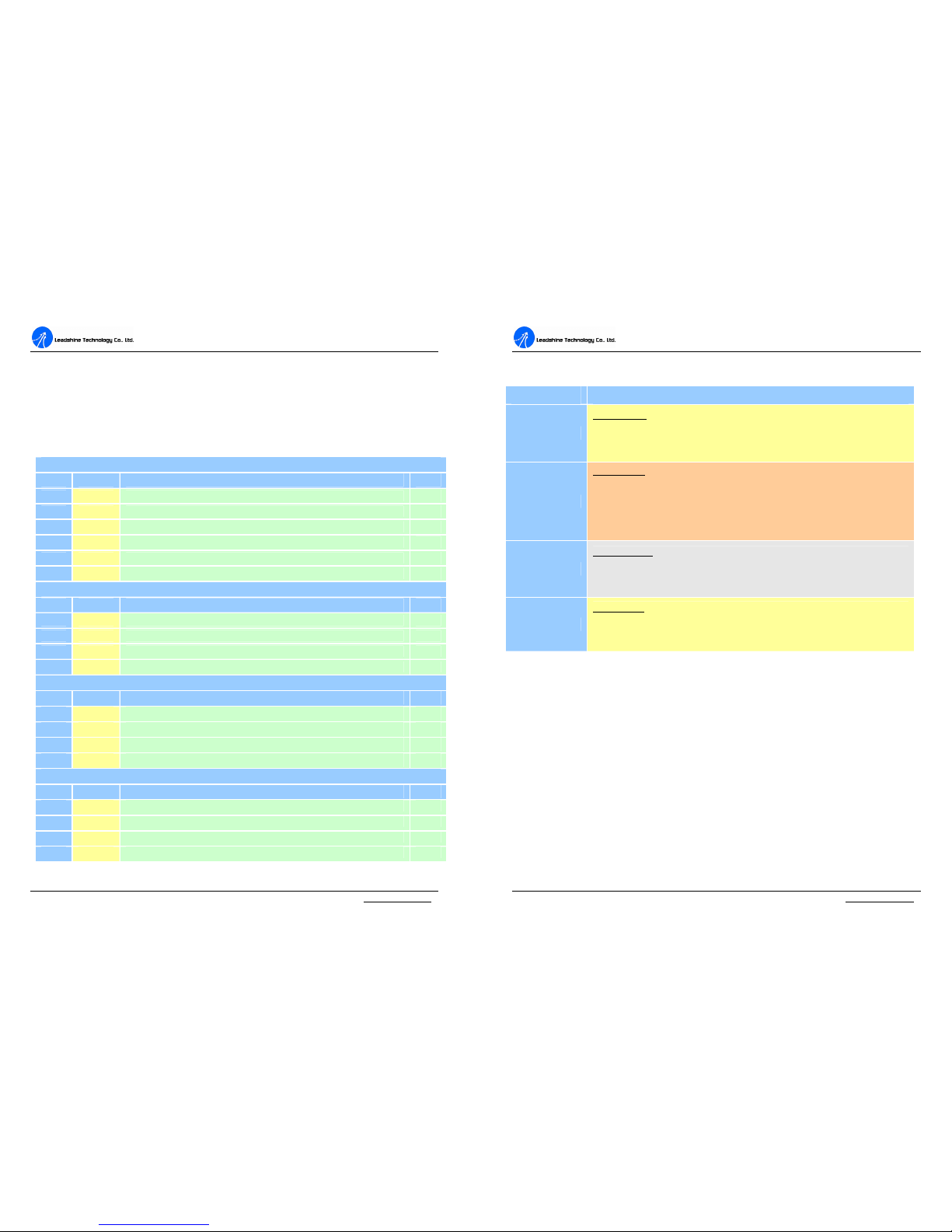

ConnectorConfiguration......................................................................................4

Generalinformation....................................................................................4

MoreaboutPUL/DIR/ENASignals............................................................5

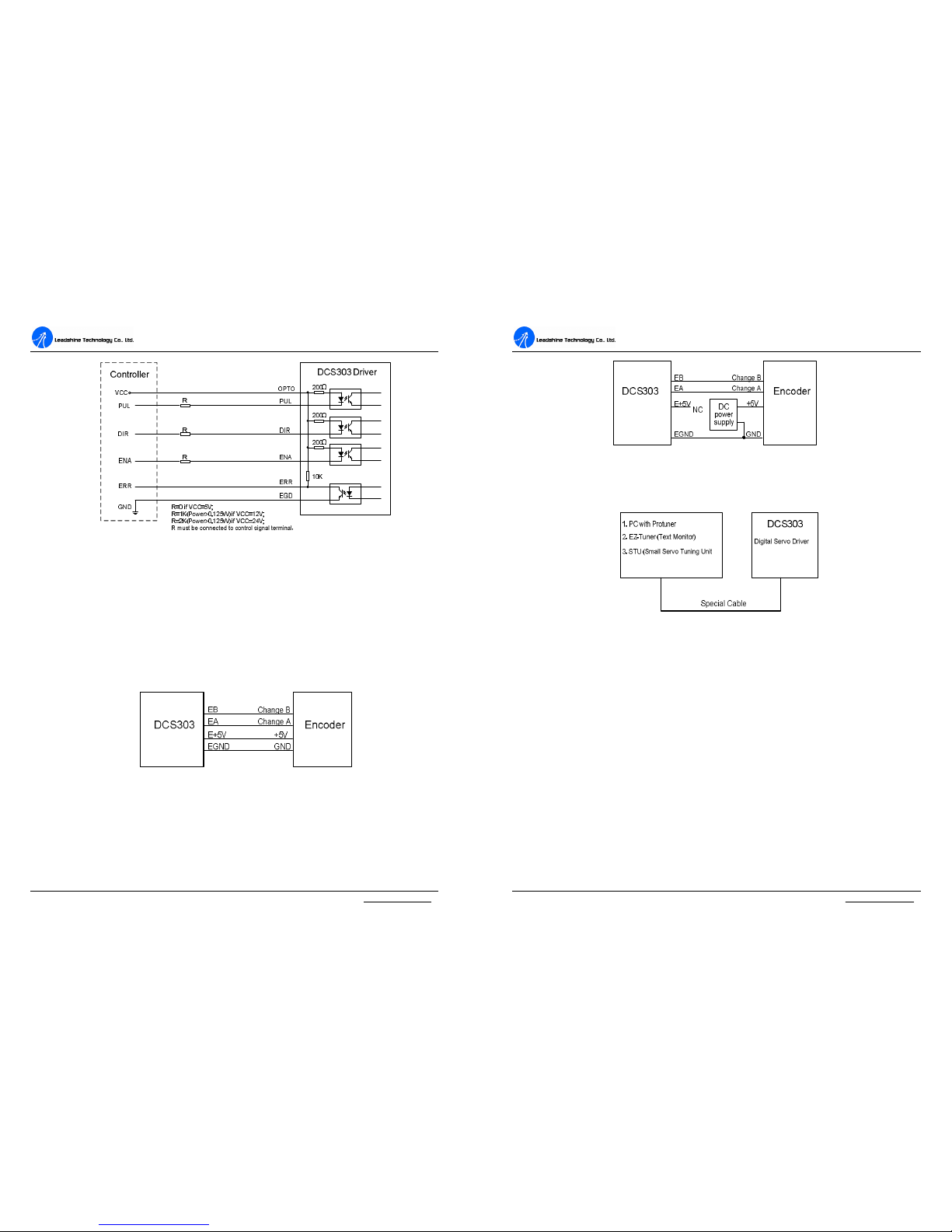

ControlSignalConnections..................................................................................5

EncoderConnections............................................................................................6

RS232 Interface Connection.................................................................................7

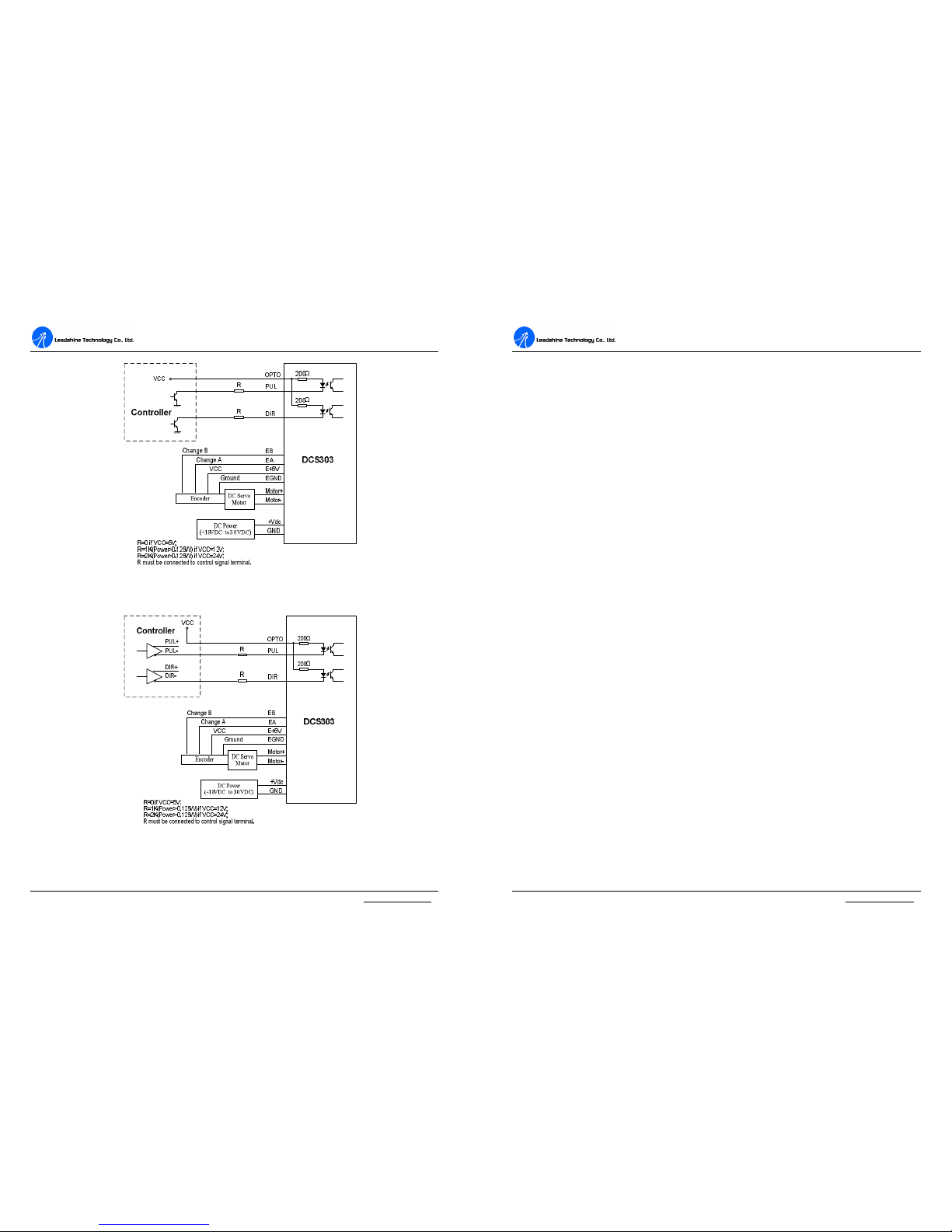

TypicalConnections.............................................................................................7

4. ServoSetup.............................................................................................................9

Install Encoder......................................................................................................9

PreparePowerSupply..........................................................................................9

RegulatedorUnregulatedPowerSupply....................................................9

SelectingSupplyVoltage.............................................................................9

PrepareController..............................................................................................10

SystemConnectionsandNoisePrevention........................................................10

WireGauge................................................................................................10

CableRouting............................................................................................11

Contents

Tel: (86)755-26434369II Website: www.leadshine.com

Twisted Wires............................................................................................11

CableShielding.........................................................................................11

SystemGrounding.....................................................................................11

PowerSupplyConnection.........................................................................12

5. Tuningtheservo....................................................................................................12

Testingtheservo.................................................................................................12

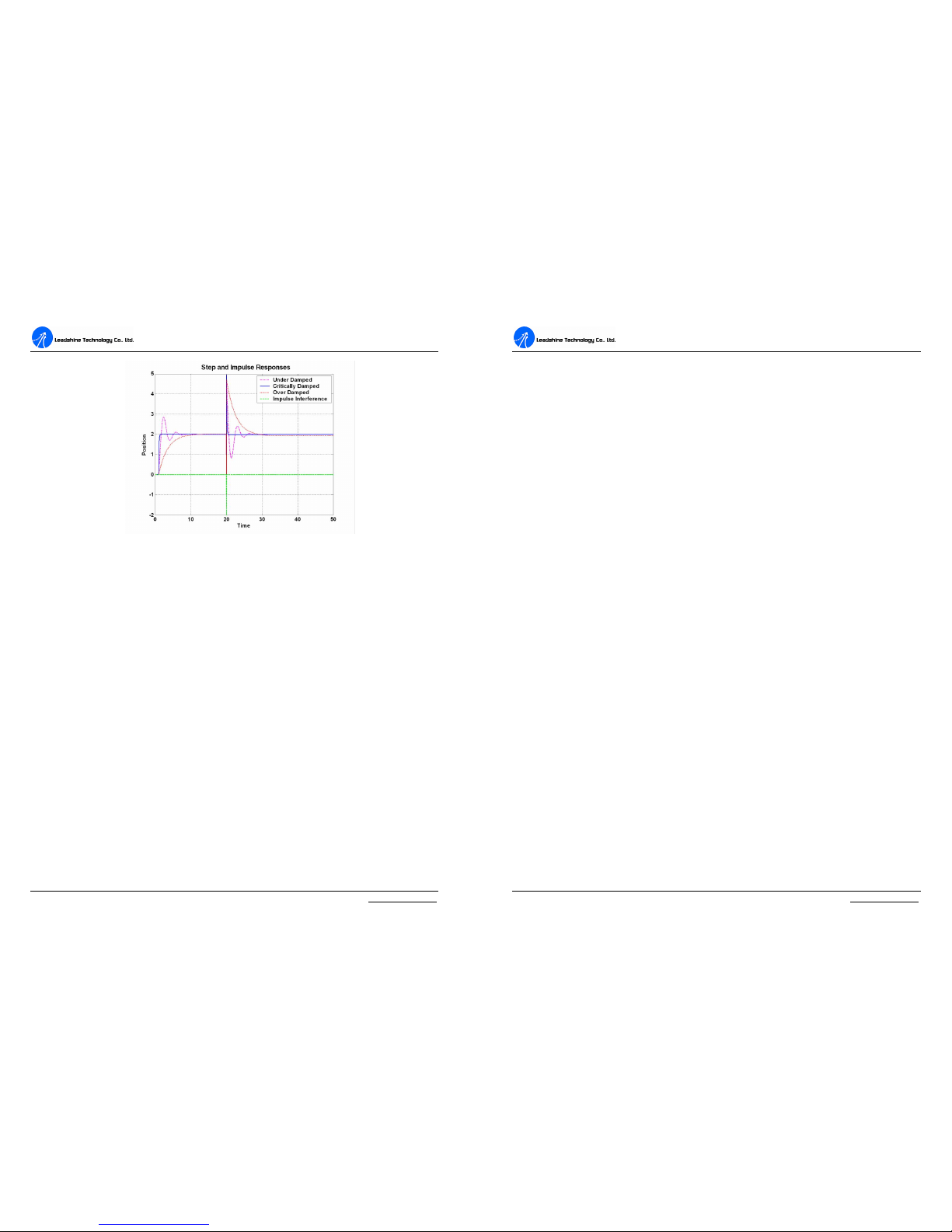

TuningtheServo................................................................................................13

6. PCwindowbasedTuningUsingProTuner...........................................................15

Introduction........................................................................................................15

SoftwareInstallation..........................................................................................15

RS232 Interface Connection..............................................................................19

Testingtheservo.................................................................................................20

SoftwareIntroduction.........................................................................................21

ProTunerMain Window............................................................................21

ComConfig Window................................................................................22

ServoTuning......................................................................................................30

Position LoopIntroduction.......................................................................30

Position aroundVelocity...........................................................................31

Position aroundTorque.............................................................................31

Position LoopTuning................................................................................32

7. UsingTips.............................................................................................................40

SequenceChartofControlSignals....................................................................40

ProtectionFunctions...........................................................................................40

Over-currentProtection.............................................................................41

Over-voltageProtection............................................................................41

PhaseErrorProtection...............................................................................41

EncoderErrorProtection...........................................................................41

Position FollowingErrorProtection.........................................................41

ProtectionIndications................................................................................42